![]() BM 2610021316

BM 2610021316

Saw Operations

Crown Molding Auxiliary fence

When making a compound cut on a molding lying flat on the table, narrow

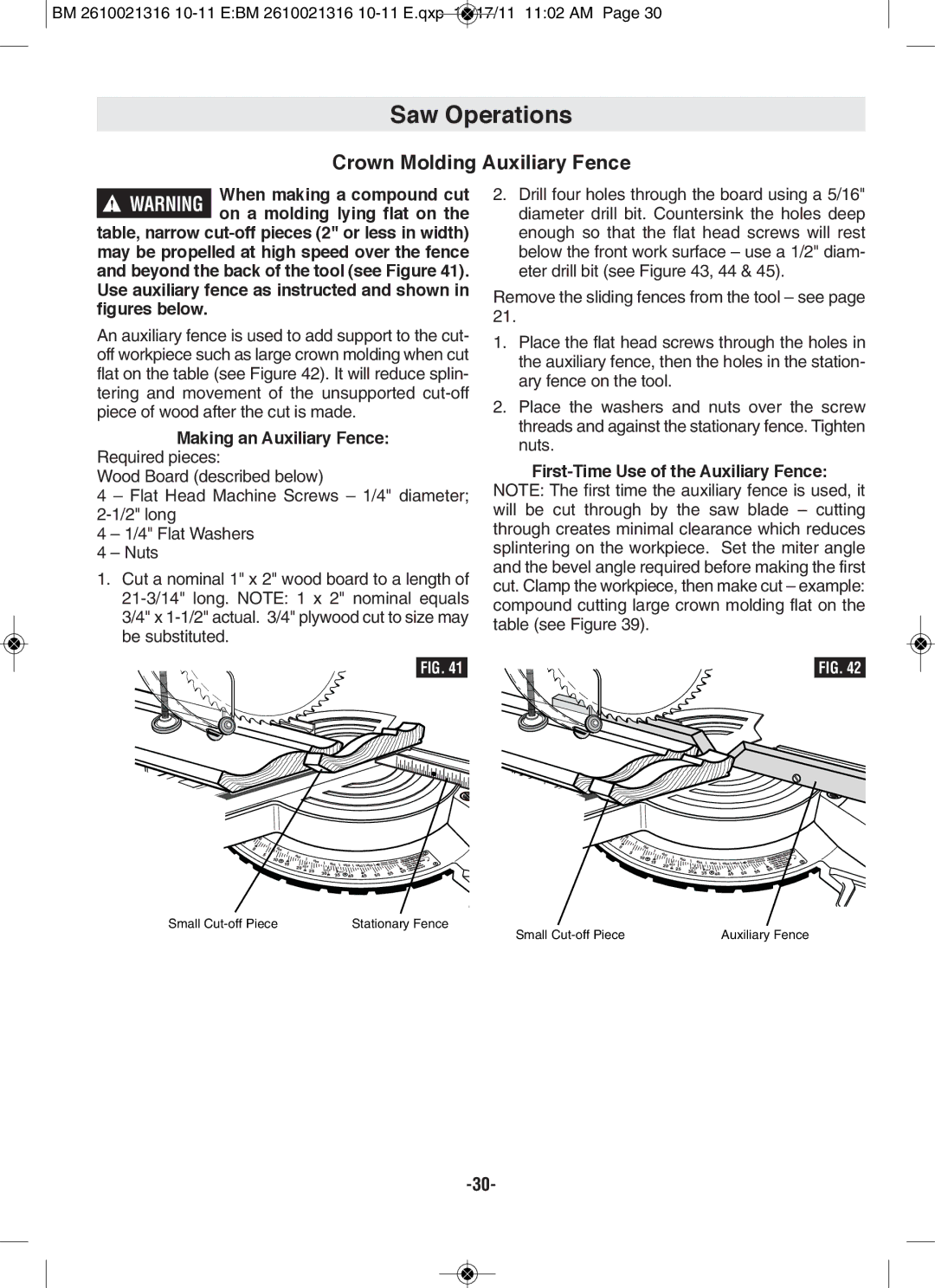

may be propelled at high speed over the fence and beyond the back of the tool (see figure 41). Use auxiliary fence as instructed and shown in figures below.

An auxiliary fence is used to add support to the cut- off workpiece such as large crown molding when cut flat on the table (see Figure 42). It will reduce splin- tering and movement of the unsupported

Making an Auxiliary fence: Required pieces:

Wood Board (described below)

4 – Flat Head Machine Screws – 1/4" diameter;

4 – 1/4" Flat Washers

4 – Nuts

1.Cut a nominal 1" x 2" wood board to a length of

FIG. 41

2.Drill four holes through the board using a 5/16" diameter drill bit. Countersink the holes deep enough so that the flat head screws will rest below the front work surface – use a 1/2" diam- eter drill bit (see Figure 43, 44 & 45).

Remove the sliding fences from the tool – see page 21.

1.Place the flat head screws through the holes in the auxiliary fence, then the holes in the station- ary fence on the tool.

2.Place the washers and nuts over the screw threads and against the stationary fence. Tighten nuts.

first-Time Use of the Auxiliary fence:

NOTE: The first time the auxiliary fence is used, it will be cut through by the saw blade – cutting through creates minimal clearance which reduces splintering on the workpiece. Set the miter angle and the bevel angle required before making the first cut. Clamp the workpiece, then make cut – example: compound cutting large crown molding flat on the table (see Figure 39).

FIG. 42

Small | Stationary Fence |

Small | Auxiliary Fence |