DIC181p

Enclosed Accessories

Accessories

Names of Machine Parts and Their Functions

Front view

Needle and presser foot section Right-side/rear view

Presser foot

Thread cassette indicator

Operation buttons

Operation panel

Stitches

Optional Accessories

Following are available as optional accessories

Sewing Machine Features

Introduction

Contents

Adjusting the Thread Tension

Adjusting the Stitch Width and Length

Sewing

Useful Sewing Tips

Stitch Settings

Maintenance

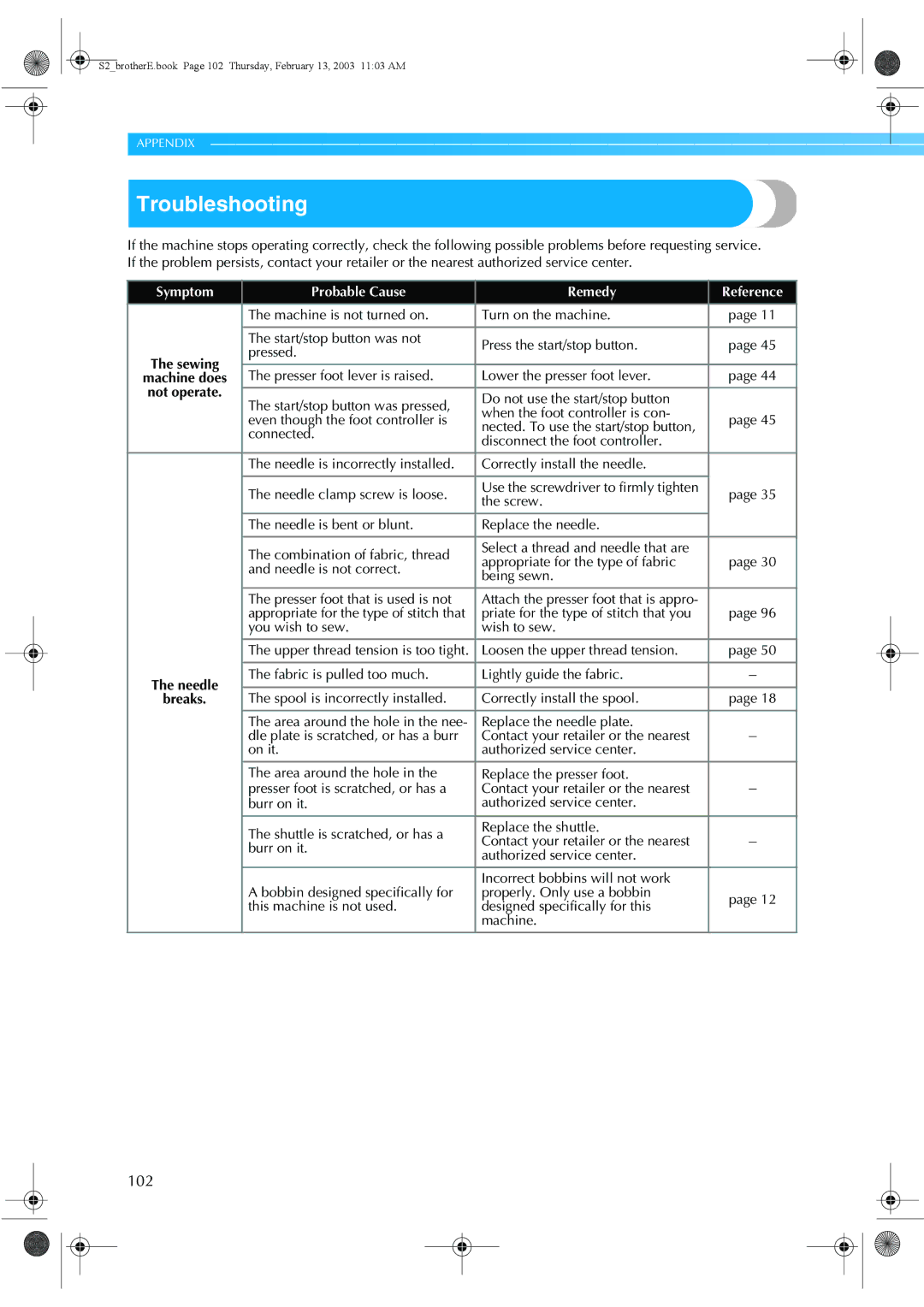

Troubleshooting

Error messages

Important Safety Instructions

For Users in the UK, EIRE, Malta and Cyprus only

Congratulations on Choosing OUR Machine

Getting Ready

Power supply precautions

Turning the Machine On/Off

3Unplug the power supply cord from the electrical outlet

4Unplug the power supply cord from the power supply jack

Turning on the machine

Turning off the machine

Winding/Installing the Bobbin

Bobbin precautions

Winding the bobbin

Move the bobbin thread spool pin up as far as possible

Winding/Installing the Bobbin

Thread is cut to a suitable length

BPress start/stop button once

Sewing machine stops

Installing the bobbin

Slide the bobbin cover latch to the right

7Reattach the bobbin cover

Upper Threading

About the spool of thread

Spools that can be loaded into the thread cassette

Spools that cannot be loaded into the thread cassette

Loading the spool into the thread cassette

Upper Threading

Thread cassette is raised

Place the spool for the upper thread onto the spool pin

Follow arrow 2 indicated on the thread cassette

Follow arrow 5 indicated on the thread cassette

Check that the thread cassette indicator is lit up in green

Threading the needle

Spool of thread is now loaded in the thread cassette

Upper threading is finished

Using the extra spool pin

5Close the thread cassette compartment cover

1Placepin. the spool of thread onto the extra spool

For more details, refer to About the spool of thread

Extra spool pin is now installed

3Install a needle

Remove the needle

Refer to Replacing the needle

Using the twin needle

For details, refer to Replacing the needle

Install the twin needle

For details, refer to Thread the needle manually

Turnstitch.on the sewing machine, and then select a

S2brotherE.book Page 28 Thursday, February 13, 2003 1103 AM

Refer to steps 1 through 5 of Installing the bobbin

Pulling up the bobbin thread

Insert the bobbin into the shuttle

Needle precautions

Replacing the Needle

Needle types and their uses

Fabrics

Checking the needle

Correct needle

Incorrect needle

Replacing the needle

Checking the needle

Install the twin needle in the same way

3Using the screwdriver, loosen the needle clamp screw

Needle is installed

4Lower the needle-changing tool

Needle can be removed from the needle bar

8Lowerneedle.the needle-changing tool off

Presser foot precautions

Replacing the Presser Foot

Replacing the presser foot

Presser foot holder releases the presser foot

Presser foot is attached

Removing the presser foot holder

Removing the presser foot holder 1Remove the presser foot

For details, refer to Replacing the presser foot

Using the optional walking foot

Attaching the walking foot 1Remove the presser foot holder

2Turn off the sewing machine

5Attach the presser foot holder

For details, refer to Removing the presser foot holder

Sewing Cylindrical Pieces

Free-arm sewing

Slide the flap off to the left

With the flap removed, free-arm sewing is possible

Sewing Basics

Sewing

General sewing procedure

Positioning the fabric

Turn on the sewing machine

3Place the fabric under the presser foot

Fabric is now positioned to be sewn

Starting to sew

Machine stops sewing with the needle lowered in the fabric

Securing the stitching

For details, refer to Starting to sew Machine starts sewing

Machine stops sewing

Machine starts sewing in the normal sewing direction

Release the start/stop button or foot controller

Sewing reinforcement stitches

When you have finished sewing, cut the threads

Cutting the thread

2Raise the presser foot lever

Threads are cut and the needle is raised

Adjusting the Thread Tension

Changing the tension of the upper thread

Correct thread tension

Upper thread is too tight

Adjusting the Stitch Width and Length

Adjusting the stitch width

Stitch width adjustment indicator lights up

Changing the needle position

Adjusting the stitch length

Stitch length adjustment indicator lights up

Useful Sewing Tips

Trial sewing

Changing the sewing direction

Sewing curves

Sewing thick fabrics

Sewing thin fabrics

Sewing stretch fabrics

Sewing an even seam allowance

Aligning the fabric with the presser foot

S2brotherE.book Page 56 Thursday, February 13, 2003 1103 AM

Utility Stitches

6Iflength,necessary,etc. width and length adjust the stitch

Selecting Stitching

Selecting stitching

Attach the presser foot

Selecting Stitching

Sewing overcasting stitches using overcasting foot G

Overcasting Stitches

Stitch

Attach overcasting foot G

Sewing overcasting stitches using zigzag foot J

Preventing fraying center baseline

Reverse stitching

Stretch fabrics

Sewing overcasting stitches using the optional side cutter

Fabric

Sewing zigzag stitches while cutting Fabric

Remove the presser foot

Guide plate

When sewing is finished, cut the thread

Basic Stitching

Basic stitching

Position

Sew a blind hem according to the following procedure

Blind Hem Stitching

For details, refer to Replacing the presser

Position the fabric with the edge of the folded

If the needle catches too much of the hem fold

Buttonhole Stitching

Buttonhole

Buttonhole sewing

If the button does not fit in the button guide plate

Size of the buttonhole is set

3Attach buttonhole foot a

4Select a stitch

For details, refer to Adjusting the stitch width

Changing the stitch width

Button sewing

Sewing buttonholes on stretch fabrics

To the right as Seen from the front of the machine

Attach button-sewing foot M

Place the button into button-sewing foot M

5Select stitch

9Start Aftersewing.sewing for about 10 seconds at low

Zipper Insertion

Inserting a centered zipper

Zipper can be sewn in place

Inserting a side zipper

6Select stitch

7Select stitch

Wrong side of fabric Mm 1/8 inch

BTopstitch around the zipper

Sewing Stretch Fabrics and Elastic Tape

Stretch stitching Elastic attaching

3Select stitch

Appliqué, Patchwork and Quilt Stitching

Quilting

Appliqué stitching

Remove the thick paper after pressing the seam allowance

4Attach zigzag foot J Select a stitch

Edge of the fabric, and sew using stitch

Patchwork crazy quilt stitching

Piecing

3Select stitch or

For details, refer to Using the optional walking foot

Quilting

Baste the fabric to be quilted Attach the walking foot

Using the optional quilting guide

Free-motion quilting

Walking foot Presser foot holder

1holder

4Slide the drop feed lever, located at the rear

Normally, the drop feed lever is positioned at the left

Reinforcement Stitching

Triple stretch stitching Bar tack stitching

Inseams

Reinforcing the ends of openings

5Pullpossible.down the buttonhole lever as far as

3Adjust the stitch width to select the desired eyelet size

Eyelet Stitching

Attach monogramming foot N

Decorative Stitching

Decorative

Fagoting

3Attach zigzag foot J

4Select stitch

Set the stitch width to 7.0 mm 1/4 inch

Scallop stitching

Smocking

4Trim along the stitches

3Sew parallel stitching at intervals of 1 cm 3/8 inch

Joining

3Select stitch , or

Heirloom stitching

4Sew along the center of the unfrayed section

S2brotherE.book Page 94 Thursday, February 13, 2003 1103 AM

Stitch Settings Maintenance

Appendix

Stitch Settings

Utility stitches

Stitch Settings

Appliqué stitch For quilting

Pattern

Maintenance

Cleaning the machine surface

Cleaning the shuttle

Needle plate cover is removed

Remove the shuttle

Grasp the shuttle, and then pull it out

Do not apply oil to the shuttle

Troubleshooting

Presser foot lever is raised Lower the presser foot lever

Loosen the upper thread tension

Clean the shuttle Bobbin designed specifically for

Correctly install the presser foot

Shuttle

Needle is bent or blunt Replace the needle

Authorized service center Bobbin designed specifically for

Thread tension is incorrect Adjust the tension of the upper

Needle was not raised

Red Green

Sewing lamp is damaged Contact your retailer or the nearest

Error messages

Operation beep

If you press

Message disappears

Changing the needle stop position

Needle stop position changes to the raised position

Index

Numerics

Index