4.All above ground gas piping upstream from manual gas valve must be electrically continuous and bonded to a grounding electrode. Do not use gas piping as a grounding electrode. Refer to the National Electrical Code, ANSI/NFPA 70 and/or CSA C22.1 Electrical Code.

C.Pressure Test. The boiler and its gas connection must be leak tested before placing boiler in operation.

1.Protect boiler gas valve. For all testing over ½ psig, boiler an its individual

½ psig or less, isolate boiler from gas supply piping by closing boiler's individual manual

2.Using soap solution, or similar

DANGER

Doe not use matches, candles, open flames or other ignition source to check for leaks.

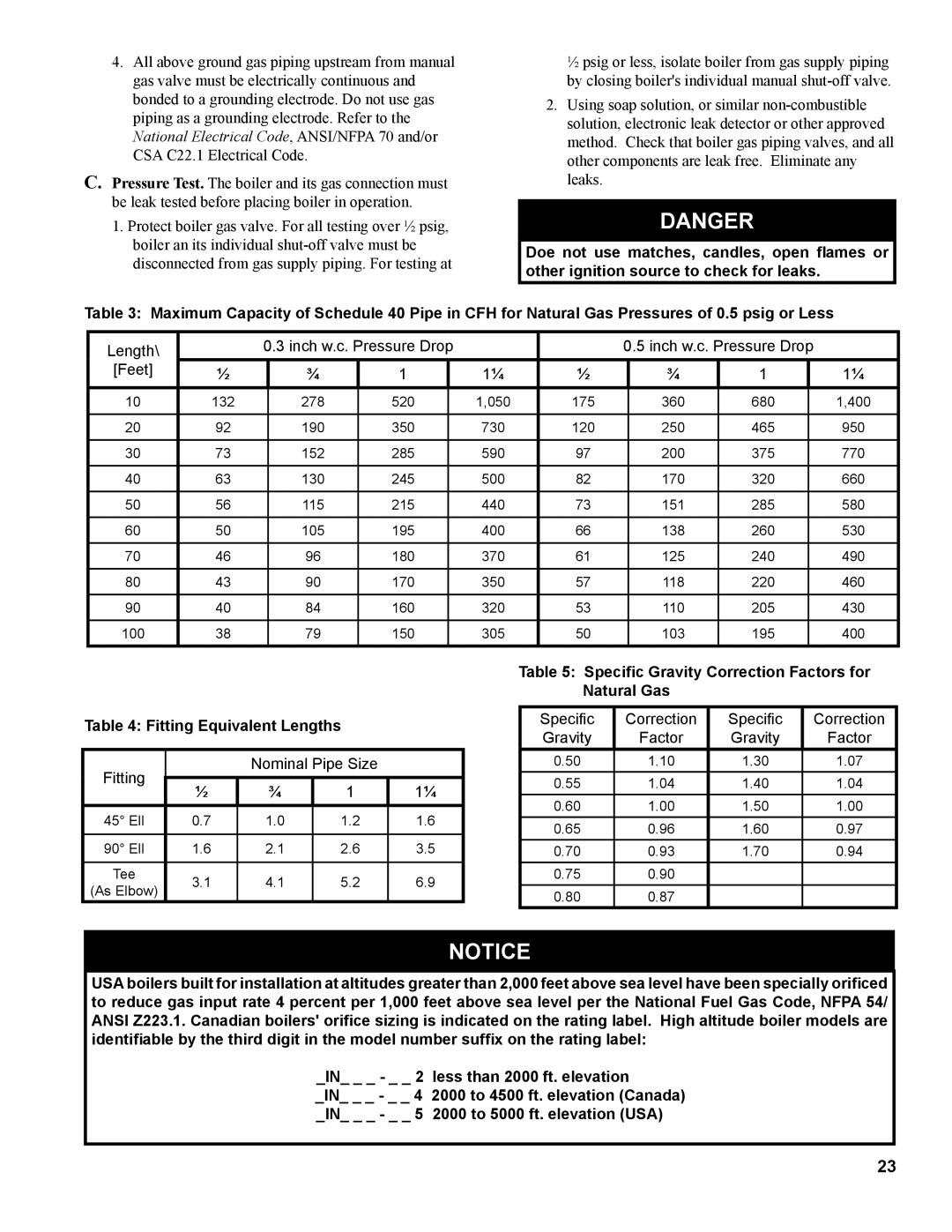

Table 3: Maximum Capacity of Schedule 40 Pipe in CFH for Natural Gas Pressures of 0.5 psig or Less

Length\ |

| 0.3 inch w.c. Pressure Drop |

|

| 0.5 inch w.c. Pressure Drop |

| ||||||

[Feet] | ½ |

| ¾ | 1 |

| 1¼ | ½ |

| ¾ | 1 |

| 1¼ |

|

|

|

|

|

|

|

|

|

|

|

|

|

10 | 132 |

| 278 | 520 |

| 1,050 | 175 |

| 360 | 680 |

| 1,400 |

|

|

|

|

|

|

|

|

|

|

|

|

|

20 | 92 |

| 190 | 350 |

| 730 | 120 |

| 250 | 465 |

| 950 |

|

|

|

|

|

|

|

|

|

|

|

|

|

30 | 73 |

| 152 | 285 |

| 590 | 97 |

| 200 | 375 |

| 770 |

|

|

|

|

|

|

|

|

|

|

|

|

|

40 | 63 |

| 130 | 245 |

| 500 | 82 |

| 170 | 320 |

| 660 |

|

|

|

|

|

|

|

|

|

|

|

|

|

50 | 56 |

| 115 | 215 |

| 440 | 73 |

| 151 | 285 |

| 580 |

|

|

|

|

|

|

|

|

|

|

|

|

|

60 | 50 |

| 105 | 195 |

| 400 | 66 |

| 138 | 260 |

| 530 |

|

|

|

|

|

|

|

|

|

|

|

|

|

70 | 46 |

| 96 | 180 |

| 370 | 61 |

| 125 | 240 |

| 490 |

|

|

|

|

|

|

|

|

|

|

|

|

|

80 | 43 |

| 90 | 170 |

| 350 | 57 |

| 118 | 220 |

| 460 |

|

|

|

|

|

|

|

|

|

|

|

|

|

90 | 40 |

| 84 | 160 |

| 320 | 53 |

| 110 | 205 |

| 430 |

|

|

|

|

|

|

|

|

|

|

|

|

|

100 | 38 |

| 79 | 150 |

| 305 | 50 |

| 103 | 195 |

| 400 |

Table 4: Fitting Equivalent Lengths

Fitting |

| Nominal Pipe Size |

| ||

½ | ¾ | 1 | 1¼ | ||

| |||||

45° Ell | 0.7 | 1.0 | 1.2 | 1.6 | |

|

|

|

|

| |

90° Ell | 1.6 | 2.1 | 2.6 | 3.5 | |

|

|

|

|

| |

Tee | 3.1 | 4.1 | 5.2 | 6.9 | |

(As Elbow) | |||||

|

|

|

| ||

Table 5: Specific Gravity Correction Factors for Natural Gas

Specific | Correction | Specific | Correction |

Gravity | Factor | Gravity | Factor |

0.50 | 1.10 | 1.30 | 1.07 |

0.55 | 1.04 | 1.40 | 1.04 |

0.60 | 1.00 | 1.50 | 1.00 |

0.65 | 0.96 | 1.60 | 0.97 |

0.70 | 0.93 | 1.70 | 0.94 |

0.75 | 0.90 |

|

|

0.80 | 0.87 |

|

|

NOTICE![]()

USA boilers built for installation at altitudes greater than 2,000 feet above sea level have been specially orificed to reduce gas input rate 4 percent per 1,000 feet above sea level per the National Fuel Gas Code, NFPA 54/ ANSI Z223.1. Canadian boilers' orifice sizing is indicated on the rating label. High altitude boiler models are identifiable by the third digit in the model number suffix on the rating label:

_IN_ _ _ - _ _ 2 | less than 2000 ft. elevation |

_IN_ _ _ - _ _ 4 | 2000 to 4500 ft. elevation (Canada) |

_IN_ _ _ - _ _ 5 | 2000 to 5000 ft. elevation (USA) |

23