II. Knocked-Down Boiler Assembly

WARNING

Installation of this boiler should be undertaken only by trained and skilled personnel from a qualified service agency.

A.Install Base-Burner-Manifold Assembly

1.

2.Unpack base assembly and place in location where boiler is to be installed (Refer to Section I: Pre- Installation).

B.Install assembled cast iron sections on base assembly:

1.Install (4) 5/16" x ¼"

(4) holes in upper base flange with screw heads on underside of flange. Note: Screws are located in fiber gasket parts bag.

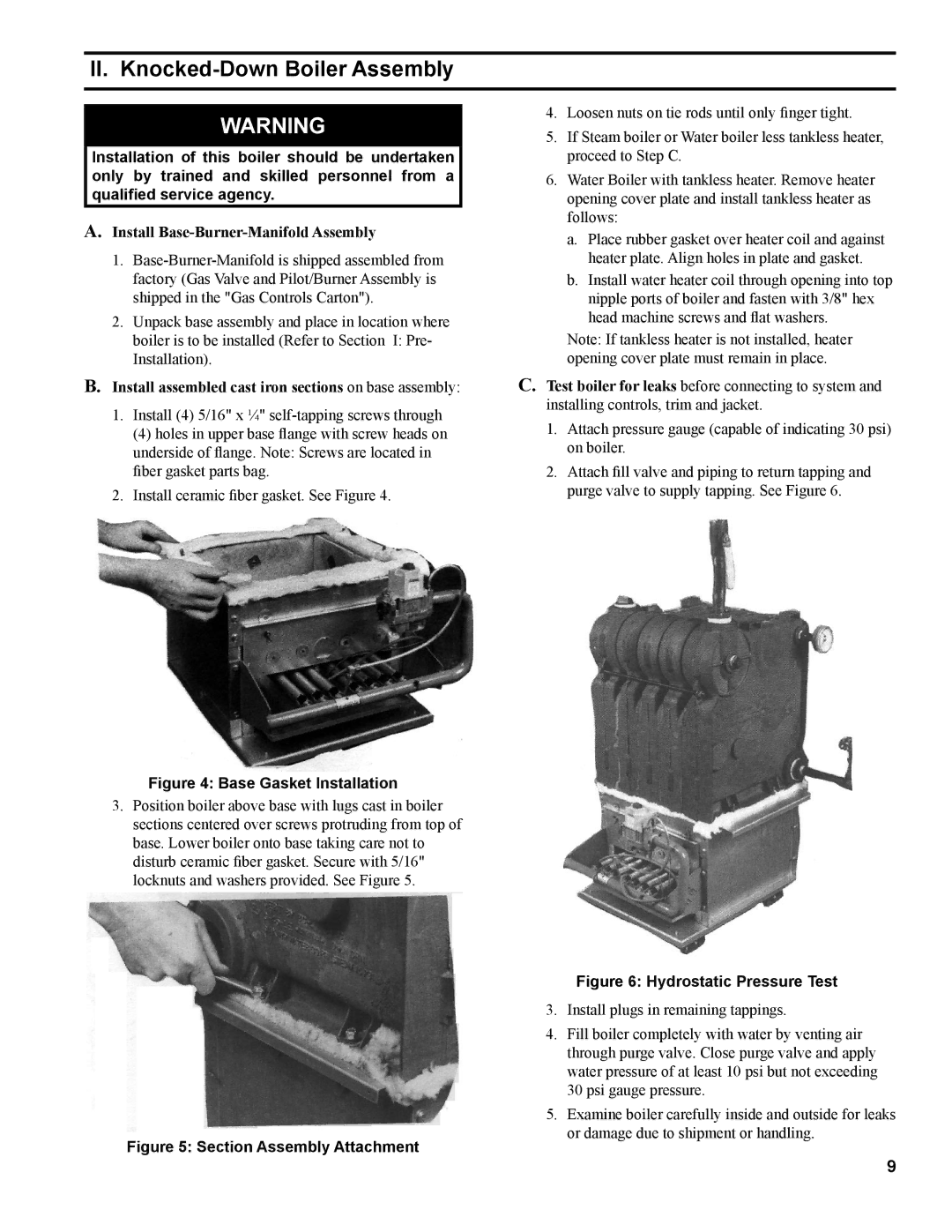

2.Install ceramic fiber gasket. See Figure 4.

4.Loosen nuts on tie rods until only finger tight.

5.If Steam boiler or Water boiler less tankless heater, proceed to Step C.

6.Water Boiler with tankless heater. Remove heater opening cover plate and install tankless heater as follows:

a.Place rubber gasket over heater coil and against heater plate. Align holes in plate and gasket.

b.Install water heater coil through opening into top nipple ports of boiler and fasten with 3/8" hex head machine screws and flat washers.

Note: If tankless heater is not installed, heater opening cover plate must remain in place.

C.Test boiler for leaks before connecting to system and installing controls, trim and jacket.

1.Attach pressure gauge (capable of indicating 30 psi) on boiler.

2.Attach fill valve and piping to return tapping and purge valve to supply tapping. See Figure 6.

Figure 4: Base Gasket Installation

3.Position boiler above base with lugs cast in boiler sections centered over screws protruding from top of base. Lower boiler onto base taking care not to disturb ceramic fiber gasket. Secure with 5/16" locknuts and washers provided. See Figure 5.

Figure 5: Section Assembly Attachment

Figure 6: Hydrostatic Pressure Test

3. Install plugs in remaining tappings.

4. Fill boiler completely with water by venting air through purge valve. Close purge valve and apply water pressure of at least 10 psi but not exceeding 30 psi gauge pressure.

5. Examine boiler carefully inside and outside for leaks or damage due to shipment or handling.