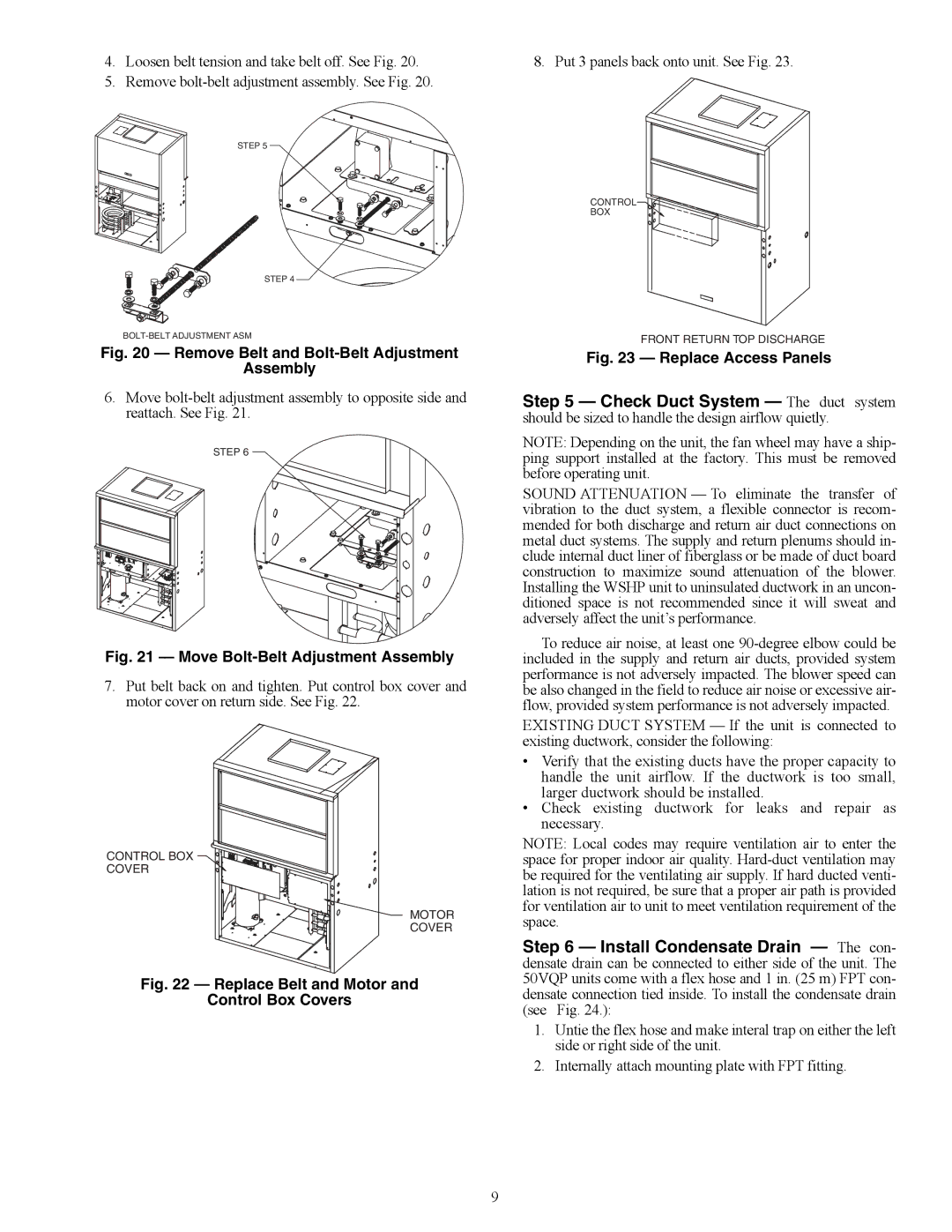

4.Loosen belt tension and take belt off. See Fig. 20.

5.Remove

a50-8482

STEP 5

8. Put 3 panels back onto unit. See Fig. 23.

CONTROL

BOX

STEP 4

a50-8485

Fig. 20 — Remove Belt and Bolt-Belt Adjustment

Assembly

6.Move

a50-8483

STEP 6

Fig. 21 — Move Bolt-Belt Adjustment Assembly

7.Put belt back on and tighten. Put control box cover and motor cover on return side. See Fig. 22.

a50-8484

CONTROL BOX

COVER

![]()

![]() MOTOR

MOTOR

COVER

Fig. 22 — Replace Belt and Motor and

Control Box Covers

FRONT RETURN TOP DISCHARGE

Fig. 23 — Replace Access Panels

Step 5 — Check Duct System — The duct system should be sized to handle the design airflow quietly.

NOTE: Depending on the unit, the fan wheel may have a ship- ping support installed at the factory. This must be removed before operating unit.

SOUND ATTENUATION — To eliminate the transfer of vibration to the duct system, a flexible connector is recom- mended for both discharge and return air duct connections on metal duct systems. The supply and return plenums should in- clude internal duct liner of fiberglass or be made of duct board construction to maximize sound attenuation of the blower. Installing the WSHP unit to uninsulated ductwork in an uncon- ditioned space is not recommended since it will sweat and adversely affect the unit’s performance.

To reduce air noise, at least one

•Verify that the existing ducts have the proper capacity to handle the unit airflow. If the ductwork is too small, larger ductwork should be installed.

•Check existing ductwork for leaks and repair as necessary.

NOTE: Local codes may require ventilation air to enter the space for proper indoor air quality.

Step 6 — Install Condensate Drain — The con- densate drain can be connected to either side of the unit. The 50VQP units come with a flex hose and 1 in. (25 m) FPT con- densate connection tied inside. To install the condensate drain (see Fig. 24.):

1.Untie the flex hose and make interal trap on either the left side or right side of the unit.

2.Internally attach mounting plate with FPT fitting.

9