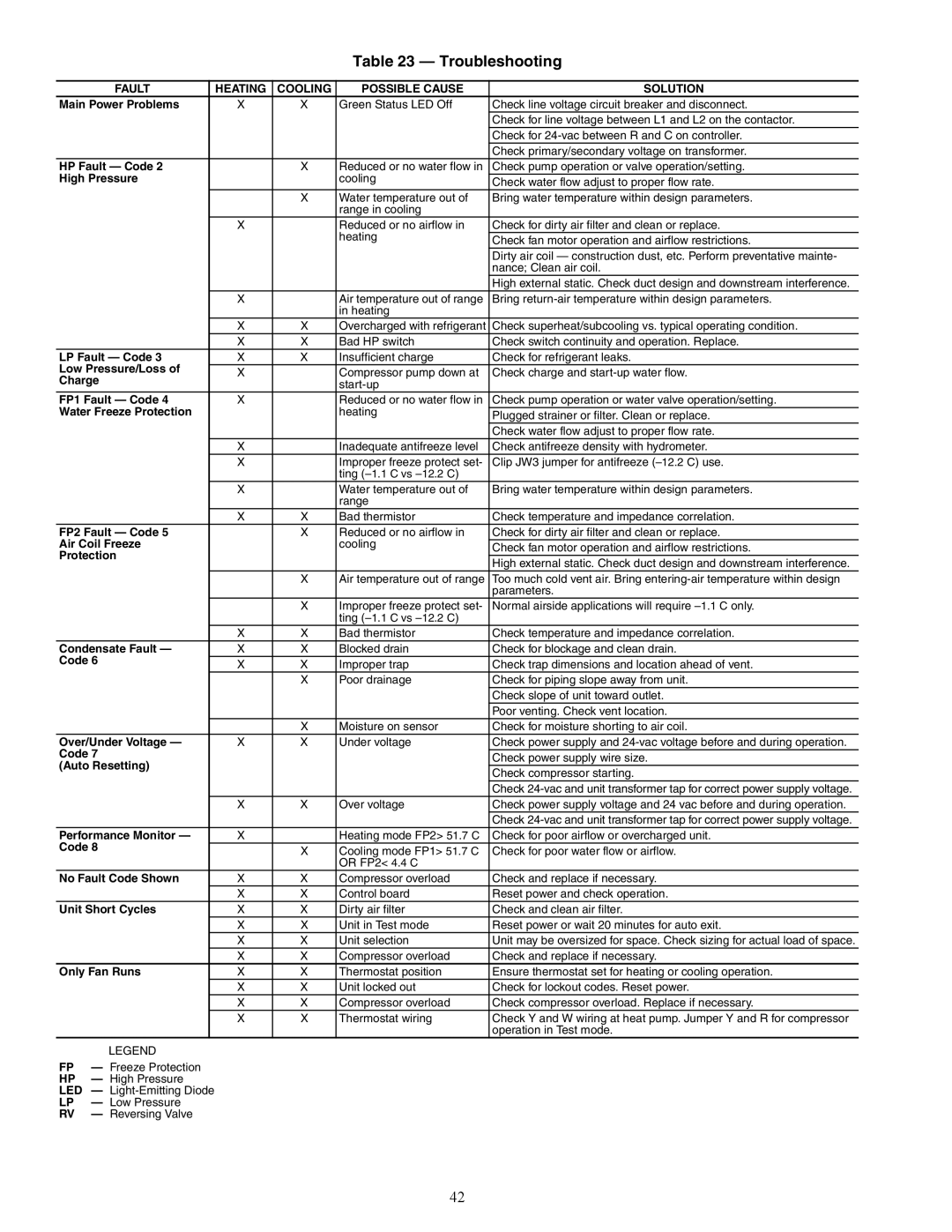

Table 23 — Troubleshooting

| FAULT |

| HEATING | COOLING | POSSIBLE CAUSE | SOLUTION |

Main Power Problems |

| X | X | Green Status LED Off | Check line voltage circuit breaker and disconnect. | |

|

|

|

|

|

| Check for line voltage between L1 and L2 on the contactor. |

|

|

|

|

|

| Check for |

|

|

|

|

|

| Check primary/secondary voltage on transformer. |

HP Fault — Code 2 |

|

| X | Reduced or no water flow in | Check pump operation or valve operation/setting. | |

High Pressure |

|

|

| cooling |

| |

|

|

| Check water flow adjust to proper flow rate. | |||

|

|

|

|

|

| |

|

|

|

| X | Water temperature out of | Bring water temperature within design parameters. |

|

|

|

|

| range in cooling |

|

|

|

| X |

| Reduced or no airflow in | Check for dirty air filter and clean or replace. |

|

|

|

|

| heating | Check fan motor operation and airflow restrictions. |

|

|

|

|

|

| |

|

|

|

|

|

| Dirty air coil — construction dust, etc. Perform preventative mainte- |

|

|

|

|

|

| nance; Clean air coil. |

|

|

|

|

|

| High external static. Check duct design and downstream interference. |

|

|

| X |

| Air temperature out of range | Bring |

|

|

|

|

| in heating |

|

|

|

| X | X | Overcharged with refrigerant | Check superheat/subcooling vs. typical operating condition. |

|

|

| X | X | Bad HP switch | Check switch continuity and operation. Replace. |

LP Fault — Code 3 |

| X | X | Insufficient charge | Check for refrigerant leaks. | |

Low Pressure/Loss of |

| X |

| Compressor pump down at | Check charge and | |

Charge |

|

| ||||

|

|

|

| |||

|

|

|

|

|

| |

FP1 Fault — Code 4 |

| X |

| Reduced or no water flow in | Check pump operation or water valve operation/setting. | |

Water Freeze Protection |

|

|

| heating |

| |

|

|

| Plugged strainer or filter. Clean or replace. | |||

|

|

|

|

|

| |

|

|

|

|

|

| Check water flow adjust to proper flow rate. |

|

|

| X |

| Inadequate antifreeze level | Check antifreeze density with hydrometer. |

|

|

| X |

| Improper freeze protect set- | Clip JW3 jumper for antifreeze |

|

|

|

|

| ting |

|

|

|

| X |

| Water temperature out of | Bring water temperature within design parameters. |

|

|

|

|

| range |

|

|

|

| X | X | Bad thermistor | Check temperature and impedance correlation. |

FP2 Fault — Code 5 |

|

| X | Reduced or no airflow in | Check for dirty air filter and clean or replace. | |

Air Coil Freeze |

|

|

| cooling | Check fan motor operation and airflow restrictions. | |

Protection |

|

|

|

| ||

|

|

|

| High external static. Check duct design and downstream interference. | ||

|

|

|

|

|

| |

|

|

|

| X | Air temperature out of range | Too much cold vent air. Bring |

|

|

|

|

|

| parameters. |

|

|

|

| X | Improper freeze protect set- | Normal airside applications will require |

|

|

|

|

| ting |

|

|

|

| X | X | Bad thermistor | Check temperature and impedance correlation. |

Condensate Fault — |

| X | X | Blocked drain | Check for blockage and clean drain. | |

Code 6 |

| X | X | Improper trap | Check trap dimensions and location ahead of vent. | |

|

|

| ||||

|

|

|

| X | Poor drainage | Check for piping slope away from unit. |

|

|

|

|

|

| Check slope of unit toward outlet. |

|

|

|

|

|

| Poor venting. Check vent location. |

|

|

|

| X | Moisture on sensor | Check for moisture shorting to air coil. |

Over/Under Voltage — |

| X | X | Under voltage | Check power supply and | |

Code 7 |

|

|

|

| Check power supply wire size. | |

(Auto Resetting) |

|

|

|

| ||

|

|

|

| Check compressor starting. | ||

|

|

|

|

|

| |

|

|

|

|

|

| Check |

|

|

| X | X | Over voltage | Check power supply voltage and 24 vac before and during operation. |

|

|

|

|

|

| Check |

Performance Monitor — |

| X |

| Heating mode FP2> 51.7 C | Check for poor airflow or overcharged unit. | |

Code 8 |

|

| X | Cooling mode FP1> 51.7 C | Check for poor water flow or airflow. | |

|

|

|

|

| OR FP2< 4.4 C |

|

No Fault Code Shown |

| X | X | Compressor overload | Check and replace if necessary. | |

|

|

| X | X | Control board | Reset power and check operation. |

Unit Short Cycles |

| X | X | Dirty air filter | Check and clean air filter. | |

|

|

| X | X | Unit in Test mode | Reset power or wait 20 minutes for auto exit. |

|

|

| X | X | Unit selection | Unit may be oversized for space. Check sizing for actual load of space. |

|

|

| X | X | Compressor overload | Check and replace if necessary. |

Only Fan Runs |

| X | X | Thermostat position | Ensure thermostat set for heating or cooling operation. | |

|

|

| X | X | Unit locked out | Check for lockout codes. Reset power. |

|

|

| X | X | Compressor overload | Check compressor overload. Replace if necessary. |

|

|

| X | X | Thermostat wiring | Check Y and W wiring at heat pump. Jumper Y and R for compressor |

|

|

|

|

|

| operation in Test mode. |

| LEGEND |

|

|

|

| |

FP | — Freeze Protection |

|

|

|

| |

HP | — High Pressure |

|

|

|

| |

LED — |

|

|

|

| ||

LP | — Low Pressure |

|

|

|

| |

RV | — Reversing Valve |

|

|

|

| |

42