|

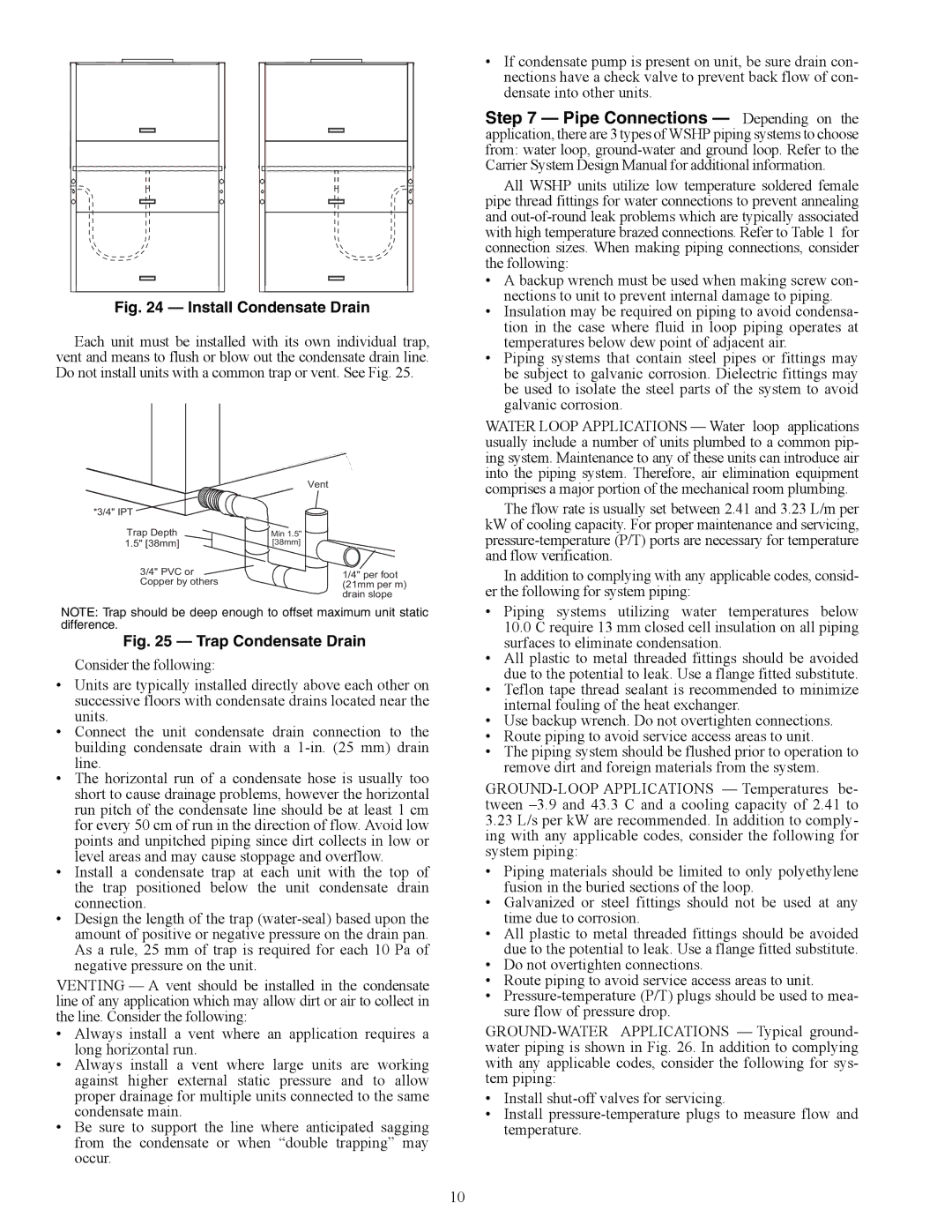

Fig. 24 — Install Condensate Drain

Each unit must be installed with its own individual trap, vent and means to flush or blow out the condensate drain line. Do not install units with a common trap or vent. See Fig. 25.

Vent

*3/4" IPT

Trap Depth | Min 1.5" |

1.5" [38mm] | [38mm] |

3/4" PVC or | 1/4" per foot |

Copper by others | (21mm per m) |

| drain slope |

NOTE: Trap should be deep enough to offset maximum unit static difference.

Fig. 25 — Trap Condensate Drain

Consider the following:

•Units are typically installed directly above each other on successive floors with condensate drains located near the units.

•Connect the unit condensate drain connection to the building condensate drain with a

•The horizontal run of a condensate hose is usually too short to cause drainage problems, however the horizontal run pitch of the condensate line should be at least 1 cm for every 50 cm of run in the direction of flow. Avoid low points and unpitched piping since dirt collects in low or level areas and may cause stoppage and overflow.

•Install a condensate trap at each unit with the top of the trap positioned below the unit condensate drain connection.

•Design the length of the trap

VENTING — A vent should be installed in the condensate line of any application which may allow dirt or air to collect in the line. Consider the following:

•Always install a vent where an application requires a long horizontal run.

•Always install a vent where large units are working against higher external static pressure and to allow proper drainage for multiple units connected to the same condensate main.

•Be sure to support the line where anticipated sagging from the condensate or when “double trapping” may occur.

•If condensate pump is present on unit, be sure drain con- nections have a check valve to prevent back flow of con- densate into other units.

Step 7 — Pipe Connections — Depending on the application, there are 3 types of WSHP piping systems to choose from: water loop,

All WSHP units utilize low temperature soldered female pipe thread fittings for water connections to prevent annealing and

•A backup wrench must be used when making screw con- nections to unit to prevent internal damage to piping.

•Insulation may be required on piping to avoid condensa- tion in the case where fluid in loop piping operates at temperatures below dew point of adjacent air.

•Piping systems that contain steel pipes or fittings may be subject to galvanic corrosion. Dielectric fittings may be used to isolate the steel parts of the system to avoid galvanic corrosion.

WATER LOOP APPLICATIONS — Water loop applications usually include a number of units plumbed to a common pip- ing system. Maintenance to any of these units can introduce air into the piping system. Therefore, air elimination equipment comprises a major portion of the mechanical room plumbing.

The flow rate is usually set between 2.41 and 3.23 L/m per kW of cooling capacity. For proper maintenance and servicing,

In addition to complying with any applicable codes, consid- er the following for system piping:

•Piping systems utilizing water temperatures below 10.0 C require 13 mm closed cell insulation on all piping

surfaces to eliminate condensation.

•All plastic to metal threaded fittings should be avoided due to the potential to leak. Use a flange fitted substitute.

•Teflon tape thread sealant is recommended to minimize internal fouling of the heat exchanger.

•Use backup wrench. Do not overtighten connections.

•Route piping to avoid service access areas to unit.

•The piping system should be flushed prior to operation to remove dirt and foreign materials from the system.

3.23L/s per kW are recommended. In addition to comply- ing with any applicable codes, consider the following for system piping:

•Piping materials should be limited to only polyethylene fusion in the buried sections of the loop.

•Galvanized or steel fittings should not be used at any time due to corrosion.

•All plastic to metal threaded fittings should be avoided due to the potential to leak. Use a flange fitted substitute.

•Do not overtighten connections.

•Route piping to avoid service access areas to unit.

•

•Install

•Install

10