PROTECTION — Once the units are properly positioned on the jobsite, they must be covered with either a shipping carton, vinyl film, or an equivalent protective covering. Open ends of pipes stored on the jobsite must be capped. This precaution is especially important in areas where painting, plastering, or spraying of fireproof material, etc. is not yet complete. Foreign material that is allowed to accumulate within the units can pre- vent proper

Before installing any of the system components, be sure to examine each pipe, fitting, and valve, and remove any dirt or foreign material found in or on these components.

![]() CAUTION

CAUTION

DO NOT store or install units in corrosive environments or in locations subject to temperature or humidity extremes (e.g., attics, garages, rooftops, etc.). Corrosive conditions and high temperature or humidity can significantly reduce performance, reliability, and service life. Always move units in an upright position. Tilting units on their sides may cause equipment damage.

INSPECT UNIT — To prepare the unit for installation, com- plete the procedures listed below:

1.Compare the electrical data on the unit nameplate with ordering and shipping information to verify that the correct unit has been shipped.

2.Do not remove the packaging until the unit is ready for installation.

3.Verify that the unit’s refrigerant tubing is free of kinks or dents, and that it does not touch other unit components.

4.Inspect all electrical connections. Be sure connections are clean and tight at their terminations.

5.Loosen compressor bolts until the compressor rides freely on springs. Remove shipping restraints.

6.Remove the four 1/4 in. (6 mm) shipping bolts from com- pressor support plate (two bolts on each side) to maxi- mize vibration and sound alternation.

![]() CAUTION

CAUTION

Failure to remove shipping brackets from

7.Remove any blower support cardboard from inlet of the blower.

8.Locate and verify any accessory kit located in compressor and/or blower section.

9.Remove any access panel screws that may be difficult to remove once unit is installed.

Step 3 — Locate Unit — The following guidelines should be considered when choosing a location for a WSHP:

•Units are for indoor use only.

•Locate in areas where ambient temperatures are between 4.4 C and 37.8 C and relative humidity is no greater than 75%.

•Provide sufficient space for water, electrical and duct connections.

NOTE: Water inlets/outlets and high/low voltage electrical access are available on either side of the unit. Electrical ac- cess is also available on the unit front. See Fig. 2 and 3.

•Locate unit in an area that allows for easy access and removal of filter and access panels.

NOTE: Unit has full filter frame bottom access for 25, 51, or 102 mm filters.

•ALLOW enough space for service personnel to perform maintenance.

•Provisions must be made for return air to freely enter the space if unit needs to be installed in a confined area such as a closet.

Step 4 — Mount the Unit — Vertical units are avail- able in rear or front return air configurations.

DISCHARGE CONFIGURATION CONVERSION — To change the discharge configuration of the unit from top dis- charge to straight (right or left) discharge, follow the procedure below. To change the discharge configuration of the unit from straight (right or left) discharge to top discharge, reverse the procedure below.

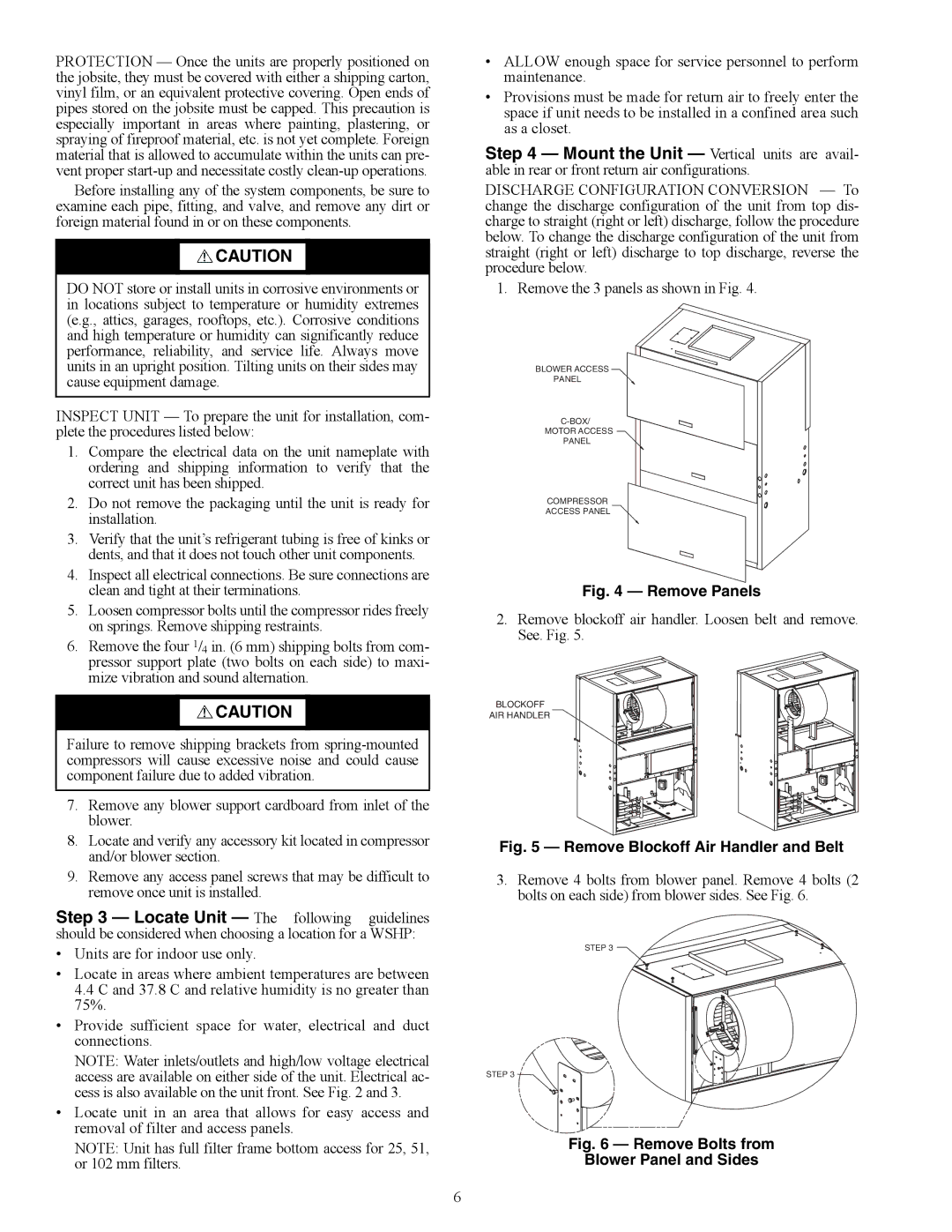

1. Remove the 3 panels as shown in Fig. 4.

BLOWER ACCESS

PANEL

MOTOR ACCESS

PANEL

COMPRESSOR

ACCESS PANEL![]()

a50-8466

Fig. 4 — Remove Panels

2.Remove blockoff air handler. Loosen belt and remove. See. Fig. 5.

a50-8467

BLOCKOFF

AIR HANDLER

Fig. 5 — Remove Blockoff Air Handler and Belt

3.Remove 4 bolts from blower panel. Remove 4 bolts (2 bolts on each side) from blower sides. See Fig. 6.

STEP 3 ![]()

![]()

a50-8468

STEP 3 ![]()

Fig. 6 — Remove Bolts from

Blower Panel and Sides

6