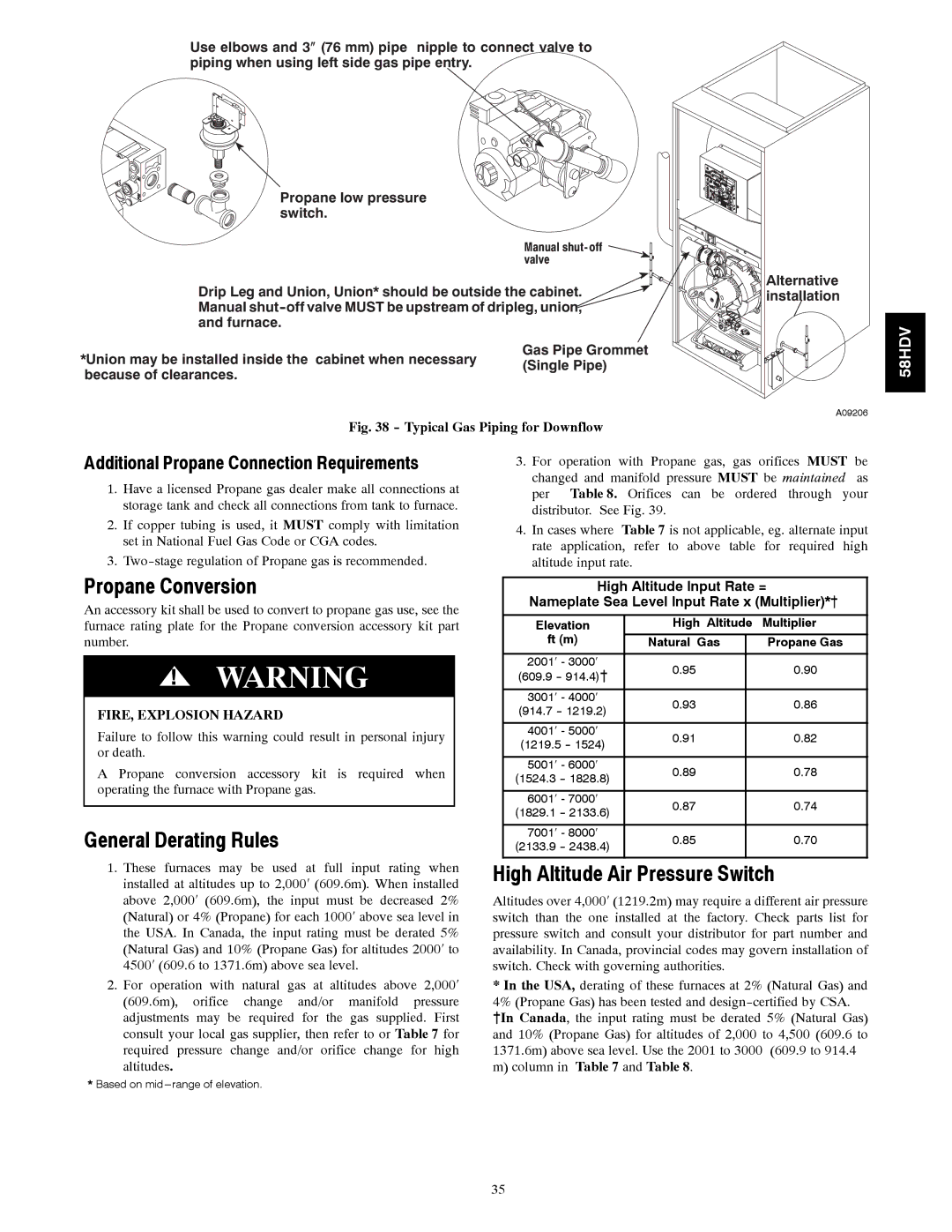

Use elbows and 3″ (76 mm) pipe nipple to connect valve to piping when using left side gas pipe entry.

Propane low pressure switch.

| Manual shut- off | |

| valve | |

Drip Leg and Union, Union* should be outside the cabinet. | ||

Manual | ||

and furnace. |

| |

*Union may be installed inside the cabinet when necessary | Gas Pipe Grommet | |

(Single Pipe) | ||

because of clearances. | ||

| ||

Alternative installation

A09206

58HDV

Fig. 38 - Typical Gas Piping for Downflow

Additional Propane Connection Requirements

1.Have a licensed Propane gas dealer make all connections at storage tank and check all connections from tank to furnace.

2.If copper tubing is used, it MUST comply with limitation set in National Fuel Gas Code or CGA codes.

3.

Propane Conversion

An accessory kit shall be used to convert to propane gas use, see the furnace rating plate for the Propane conversion accessory kit part number.

!WARNING

FIRE, EXPLOSION HAZARD

Failure to follow this warning could result in personal injury or death.

A Propane conversion accessory kit is required when operating the furnace with Propane gas.

General Derating Rules

1.These furnaces may be used at full input rating when installed at altitudes up to 2,000′ (609.6m). When installed above 2,000′ (609.6m), the input must be decreased 2% (Natural) or 4% (Propane) for each 1000′ above sea level in the USA. In Canada, the input rating must be derated 5% (Natural Gas) and 10% (Propane Gas) for altitudes 2000′ to 4500′ (609.6 to 1371.6m) above sea level.

2.For operation with natural gas at altitudes above 2,000′ (609.6m), orifice change and/or manifold pressure adjustments may be required for the gas supplied. First consult your local gas supplier, then refer to or Table 7 for required pressure change and/or orifice change for high altitudes.

*Based on

3.For operation with Propane gas, gas orifices MUST be changed and manifold pressure MUST be maintained as per Table 8. Orifices can be ordered through your distributor. See Fig. 39.

4.In cases where Table 7 is not applicable, eg. alternate input rate application, refer to above table for required high altitude input rate.

High Altitude Input Rate =

Nameplate Sea Level Input Rate x (Multiplier)*{

Elevation | High Altitude | Multiplier | |

ft (m) | Natural Gas |

| Propane Gas |

|

|

|

|

2001′ - 3000′ | 0.95 |

| 0.90 |

(609.9 |

| ||

|

|

| |

|

|

|

|

3001′ - 4000′ | 0.93 |

| 0.86 |

(914.7 |

| ||

|

|

| |

|

|

|

|

4001′ - 5000′ | 0.91 |

| 0.82 |

(1219.5 |

| ||

|

|

| |

|

|

|

|

5001′ - 6000′ | 0.89 |

| 0.78 |

(1524.3 |

| ||

|

|

| |

|

|

|

|

6001′ - 7000′ | 0.87 |

| 0.74 |

(1829.1 |

| ||

|

|

| |

|

|

|

|

7001′ - 8000′ | 0.85 |

| 0.70 |

(2133.9 |

| ||

|

|

| |

|

|

|

|

High Altitude Air Pressure Switch

Altitudes over 4,000′ (1219.2m) may require a different air pressure switch than the one installed at the factory. Check parts list for pressure switch and consult your distributor for part number and availability. In Canada, provincial codes may govern installation of switch. Check with governing authorities.

*In the USA, derating of these furnaces at 2% (Natural Gas) and 4% (Propane Gas) has been tested and

35