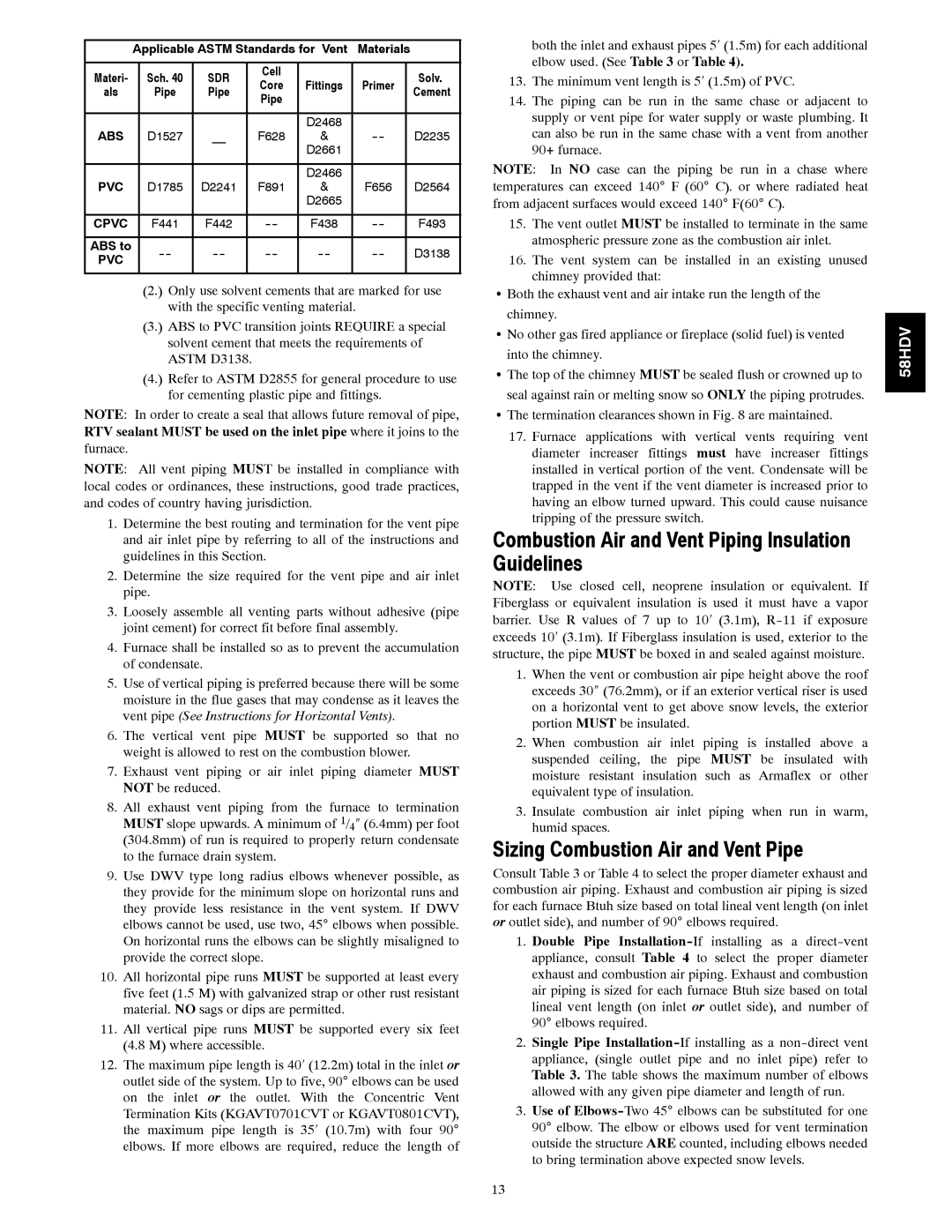

| Applicable ASTM Standards for Vent | Materials |

| |||||

|

|

|

|

|

|

|

|

|

Materi- |

| Sch. 40 | SDR | Cell |

|

|

| Solv. |

| Core | Fittings | Primer |

| ||||

als |

| Pipe | Pipe |

| Cement | |||

| Pipe |

|

|

| ||||

|

|

|

|

|

|

|

| |

|

|

|

|

|

|

|

|

|

|

|

|

|

| D2468 |

|

|

|

ABS |

| D1527 | __ | F628 | & |

| D2235 | |

|

|

|

|

| D2661 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| D2466 |

|

|

|

PVC |

| D1785 | D2241 | F891 | & | F656 |

| D2564 |

|

|

|

|

| D2665 |

|

|

|

|

|

|

|

|

|

|

|

|

CPVC |

| F441 | F442 | F438 |

| F493 | ||

|

|

|

|

|

|

|

|

|

ABS to |

|

| D3138 | |||||

PVC |

|

| ||||||

|

|

|

|

|

|

|

| |

|

|

|

|

|

|

|

|

|

(2.) Only use solvent cements that are marked for use with the specific venting material.

(3.) ABS to PVC transition joints REQUIRE a special

solvent cement that meets the requirements of ASTM D3138.

(4.) Refer to ASTM D2855 for general procedure to use for cementing plastic pipe and fittings.

NOTE: In order to create a seal that allows future removal of pipe, RTV sealant MUST be used on the inlet pipe where it joins to the furnace.

NOTE: All vent piping MUST be installed in compliance with local codes or ordinances, these instructions, good trade practices, and codes of country having jurisdiction.

1.Determine the best routing and termination for the vent pipe and air inlet pipe by referring to all of the instructions and guidelines in this Section.

2.Determine the size required for the vent pipe and air inlet pipe.

3.Loosely assemble all venting parts without adhesive (pipe joint cement) for correct fit before final assembly.

4.Furnace shall be installed so as to prevent the accumulation of condensate.

5.Use of vertical piping is preferred because there will be some moisture in the flue gases that may condense as it leaves the vent pipe (See Instructions for Horizontal Vents).

6.The vertical vent pipe MUST be supported so that no weight is allowed to rest on the combustion blower.

7.Exhaust vent piping or air inlet piping diameter MUST NOT be reduced.

8.All exhaust vent piping from the furnace to termination

MUST slope upwards. A minimum of 1/4″ (6.4mm) per foot (304.8mm) of run is required to properly return condensate to the furnace drain system.

9.Use DWV type long radius elbows whenever possible, as they provide for the minimum slope on horizontal runs and they provide less resistance in the vent system. If DWV elbows cannot be used, use two, 45° elbows when possible. On horizontal runs the elbows can be slightly misaligned to provide the correct slope.

10.All horizontal pipe runs MUST be supported at least every five feet (1.5 M) with galvanized strap or other rust resistant material. NO sags or dips are permitted.

11.All vertical pipe runs MUST be supported every six feet (4.8 M) where accessible.

12.The maximum pipe length is 40′ (12.2m) total in the inlet or outlet side of the system. Up to five, 90° elbows can be used on the inlet or the outlet. With the Concentric Vent Termination Kits (KGAVT0701CVT or KGAVT0801CVT), the maximum pipe length is 35′ (10.7m) with four 90° elbows. If more elbows are required, reduce the length of

both the inlet and exhaust pipes 5′ (1.5m) for each additional elbow used. (See Table 3 or Table 4).

13.The minimum vent length is 5′ (1.5m) of PVC.

14.The piping can be run in the same chase or adjacent to supply or vent pipe for water supply or waste plumbing. It can also be run in the same chase with a vent from another 90+ furnace.

NOTE: In NO case can the piping be run in a chase where temperatures can exceed 140° F (60° C). or where radiated heat from adjacent surfaces would exceed 140° F(60° C).

15.The vent outlet MUST be installed to terminate in the same atmospheric pressure zone as the combustion air inlet.

16.The vent system can be installed in an existing unused chimney provided that:

SBoth the exhaust vent and air intake run the length of the chimney.

SNo other gas fired appliance or fireplace (solid fuel) is vented into the chimney.

SThe top of the chimney MUST be sealed flush or crowned up to seal against rain or melting snow so ONLY the piping protrudes.

SThe termination clearances shown in Fig. 8 are maintained.

17.Furnace applications with vertical vents requiring vent diameter increaser fittings must have increaser fittings installed in vertical portion of the vent. Condensate will be trapped in the vent if the vent diameter is increased prior to having an elbow turned upward. This could cause nuisance tripping of the pressure switch.

Combustion Air and Vent Piping Insulation Guidelines

NOTE: Use closed cell, neoprene insulation or equivalent. If Fiberglass or equivalent insulation is used it must have a vapor barrier. Use R values of 7 up to 10′ (3.1m),

1.When the vent or combustion air pipe height above the roof exceeds 30″ (76.2mm), or if an exterior vertical riser is used on a horizontal vent to get above snow levels, the exterior portion MUST be insulated.

2.When combustion air inlet piping is installed above a suspended ceiling, the pipe MUST be insulated with moisture resistant insulation such as Armaflex or other equivalent type of insulation.

3.Insulate combustion air inlet piping when run in warm, humid spaces.

Sizing Combustion Air and Vent Pipe

Consult Table 3 or Table 4 to select the proper diameter exhaust and combustion air piping. Exhaust and combustion air piping is sized for each furnace Btuh size based on total lineal vent length (on inlet or outlet side), and number of 90° elbows required.

1.Double Pipe

2.Single Pipe

3.Use of

58HDV

13