Antifreeze — In areas where entering loop temperatures drop below 40 F or where piping will be routed through areas subject to freezing, antifreeze is needed.

Alcohols and glycols are commonly used as antifreeze agents. Freeze protection should be maintained to 15 F below the lowest expected entering loop temperature. For example, if the lowest expected entering loop temperature is 30 F, the leaving loop temperature would be 22 to 25 F. Therefore, the freeze protection should be at 15 F (30 F – 15 F = 15 F).

IMPORTANT: All alcohols should be pre-mixed and pumped from a reservoir outside of the building or introduced under water level to prevent fuming.

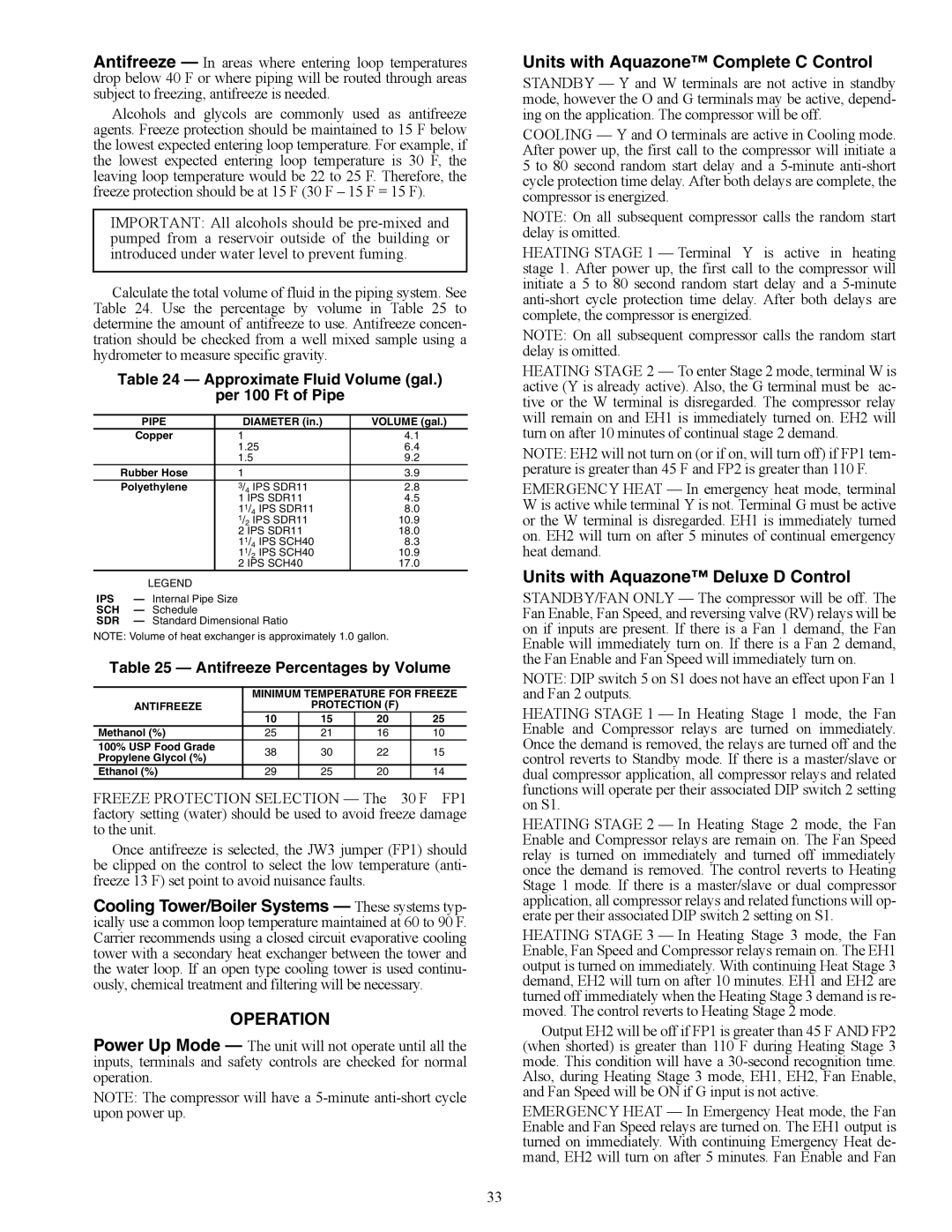

Calculate the total volume of fluid in the piping system. See Table 24. Use the percentage by volume in Table 25 to determine the amount of antifreeze to use. Antifreeze concen- tration should be checked from a well mixed sample using a hydrometer to measure specific gravity.

Table 24 — Approximate Fluid Volume (gal.)

per 100 Ft of Pipe

| PIPE | | DIAMETER (in.) | VOLUME (gal.) |

| Copper | | 1 | 4.1 |

| | | 1.25 | 6.4 |

| | | 1.5 | 9.2 |

| Rubber Hose | | 1 | 3.9 |

| Polyethylene | | 3/4 IPS SDR11 | 2.8 |

| | | 1 IPS SDR11 | 4.5 |

| | | 11/4 IPS SDR11 | 8.0 |

| | | 1/2 IPS SDR11 | 10.9 |

| | | 2 IPS SDR11 | 18.0 |

| | | 11/4 IPS SCH40 | 8.3 |

| | | 11/2 IPS SCH40 | 10.9 |

| | | 2 IPS SCH40 | 17.0 |

| LEGEND | | |

IPS | — Internal Pipe Size | | |

SCH | — Schedule | | |

SDR | — Standard Dimensional Ratio | |

NOTE: Volume of heat exchanger is approximately 1.0 gallon.

Table 25 — Antifreeze Percentages by Volume

| MINIMUM TEMPERATURE FOR FREEZE |

ANTIFREEZE | | PROTECTION (F) | |

| 10 | 15 | 20 | | 25 |

Methanol (%) | 25 | 21 | 16 | | 10 |

100% USP Food Grade | 38 | 30 | 22 | | 15 |

Propylene Glycol (%) | |

| | | | |

Ethanol (%) | 29 | 25 | 20 | | 14 |

FREEZE PROTECTION SELECTION — The 30 F | FP1 |

factory setting (water) should be used to avoid freeze damage to the unit.

Once antifreeze is selected, the JW3 jumper (FP1) should be clipped on the control to select the low temperature (anti- freeze 13 F) set point to avoid nuisance faults.

Cooling Tower/Boiler Systems — These systems typ- ically use a common loop temperature maintained at 60 to 90 F. Carrier recommends using a closed circuit evaporative cooling tower with a secondary heat exchanger between the tower and the water loop. If an open type cooling tower is used continu- ously, chemical treatment and filtering will be necessary.

OPERATION

Power Up Mode — The unit will not operate until all the inputs, terminals and safety controls are checked for normal operation.

NOTE: The compressor will have a 5-minute anti-short cycle upon power up.

Units with Aquazone™ Complete C Control

STANDBY — Y and W terminals are not active in standby mode, however the O and G terminals may be active, depend- ing on the application. The compressor will be off.

COOLING — Y and O terminals are active in Cooling mode. After power up, the first call to the compressor will initiate a 5 to 80 second random start delay and a 5-minute anti-short cycle protection time delay. After both delays are complete, the compressor is energized.

NOTE: On all subsequent compressor calls the random start delay is omitted.

HEATING STAGE 1 — Terminal Y is active in heating stage 1. After power up, the first call to the compressor will initiate a 5 to 80 second random start delay and a 5-minute anti-short cycle protection time delay. After both delays are complete, the compressor is energized.

NOTE: On all subsequent compressor calls the random start delay is omitted.

HEATING STAGE 2 — To enter Stage 2 mode, terminal W is active (Y is already active). Also, the G terminal must be ac- tive or the W terminal is disregarded. The compressor relay will remain on and EH1 is immediately turned on. EH2 will turn on after 10 minutes of continual stage 2 demand.

NOTE: EH2 will not turn on (or if on, will turn off) if FP1 tem- perature is greater than 45 F and FP2 is greater than 110 F.

EMERGENCY HEAT — In emergency heat mode, terminal W is active while terminal Y is not. Terminal G must be active or the W terminal is disregarded. EH1 is immediately turned on. EH2 will turn on after 5 minutes of continual emergency heat demand.

Units with Aquazone™ Deluxe D Control

STANDBY/FAN ONLY — The compressor will be off. The Fan Enable, Fan Speed, and reversing valve (RV) relays will be on if inputs are present. If there is a Fan 1 demand, the Fan Enable will immediately turn on. If there is a Fan 2 demand, the Fan Enable and Fan Speed will immediately turn on.

NOTE: DIP switch 5 on S1 does not have an effect upon Fan 1 and Fan 2 outputs.

HEATING STAGE 1 — In Heating Stage 1 mode, the Fan Enable and Compressor relays are turned on immediately. Once the demand is removed, the relays are turned off and the control reverts to Standby mode. If there is a master/slave or dual compressor application, all compressor relays and related functions will operate per their associated DIP switch 2 setting on S1.

HEATING STAGE 2 — In Heating Stage 2 mode, the Fan Enable and Compressor relays are remain on. The Fan Speed relay is turned on immediately and turned off immediately once the demand is removed. The control reverts to Heating Stage 1 mode. If there is a master/slave or dual compressor application, all compressor relays and related functions will op- erate per their associated DIP switch 2 setting on S1.

HEATING STAGE 3 — In Heating Stage 3 mode, the Fan Enable, Fan Speed and Compressor relays remain on. The EH1 output is turned on immediately. With continuing Heat Stage 3 demand, EH2 will turn on after 10 minutes. EH1 and EH2 are turned off immediately when the Heating Stage 3 demand is re- moved. The control reverts to Heating Stage 2 mode.

Output EH2 will be off if FP1 is greater than 45 F AND FP2 (when shorted) is greater than 110 F during Heating Stage 3 mode. This condition will have a 30-second recognition time. Also, during Heating Stage 3 mode, EH1, EH2, Fan Enable, and Fan Speed will be ON if G input is not active.

EMERGENCY HEAT — In Emergency Heat mode, the Fan Enable and Fan Speed relays are turned on. The EH1 output is turned on immediately. With continuing Emergency Heat de- mand, EH2 will turn on after 5 minutes. Fan Enable and Fan