SHELF MEASUREMENTS

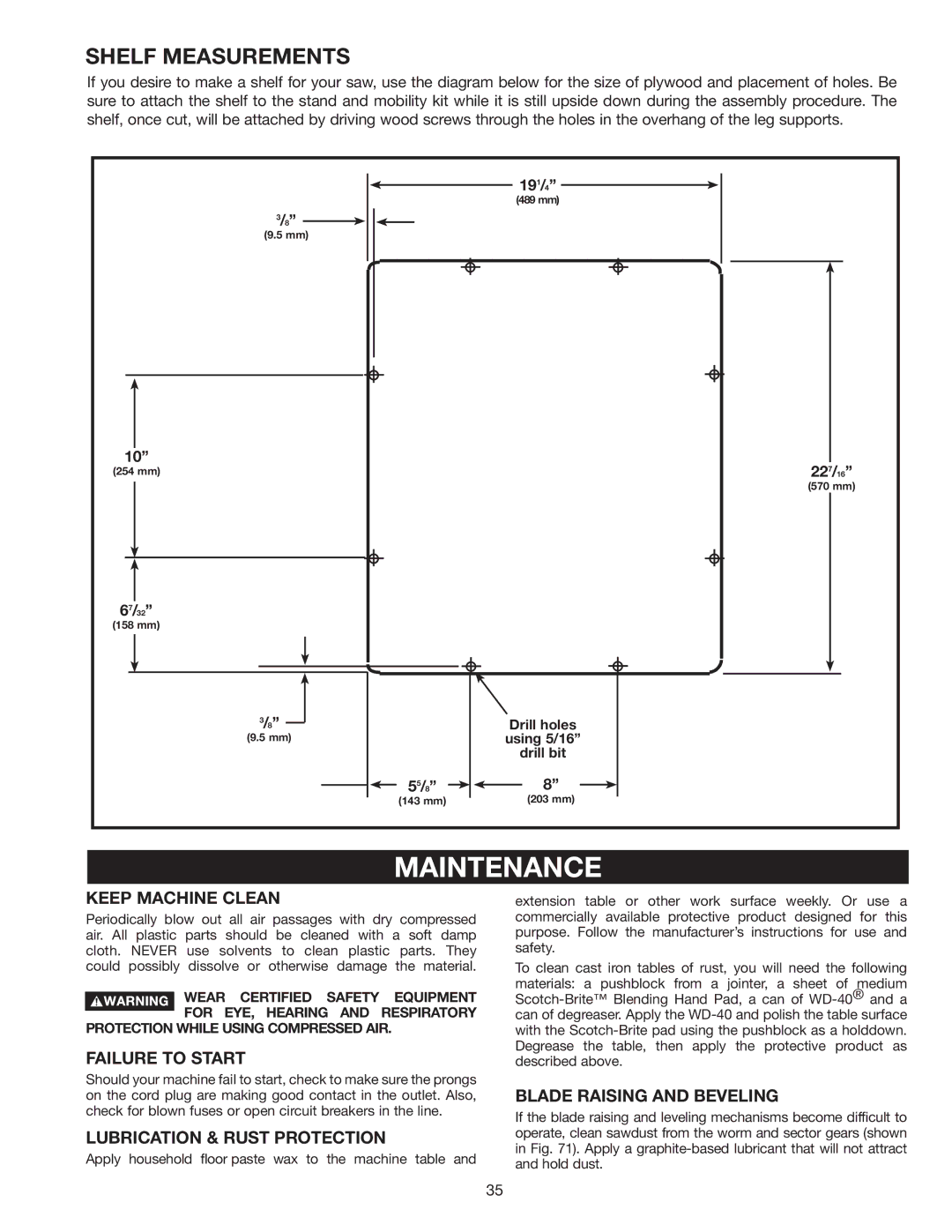

If you desire to make a shelf for your saw, use the diagram below for the size of plywood and placement of holes. Be sure to attach the shelf to the stand and mobility kit while it is still upside down during the assembly procedure. The shelf, once cut, will be attached by driving wood screws through the holes in the overhang of the leg supports.

| 191/4” |

| (489 mm) |

3/8” |

|

(9.5 mm) |

|

10” | 227/16” |

(254 mm) | |

| (570 mm) |

67/32” |

|

(158 mm) |

|

3/8” | Drill holes |

(9.5 mm) | using 5/16” |

| drill bit |

55/8” | 8” |

(143 mm) | (203 mm) |

MAINTENANCE

KEEP MACHINE CLEAN

Periodically blow out all air passages with dry compressed air. All plastic parts should be cleaned with a soft damp cloth. NEVER use solvents to clean plastic parts. They could possibly dissolve or otherwise damage the material.

WEAR CERTIFIED SAFETY EQUIPMENT FOR EYE, HEARING AND RESPIRATORY

PROTECTION WHILE USING COMPRESSED AIR.

FAILURE TO START

Should your machine fail to start, check to make sure the prongs on the cord plug are making good contact in the outlet. Also, check for blown fuses or open circuit breakers in the line.

LUBRICATION & RUST PROTECTION

Apply household floor paste wax to the machine table and

extension table or other work surface weekly. Or use a commercially available protective product designed for this purpose. Follow the manufacturer’s instructions for use and safety.

To clean cast iron tables of rust, you will need the following materials: a pushblock from a jointer, a sheet of medium

BLADE RAISING AND BEVELING

If the blade raising and leveling mechanisms become difficult to operate, clean sawdust from the worm and sector gears (shown in Fig. 71). Apply a

35