SPEC 7, |

|

|

|

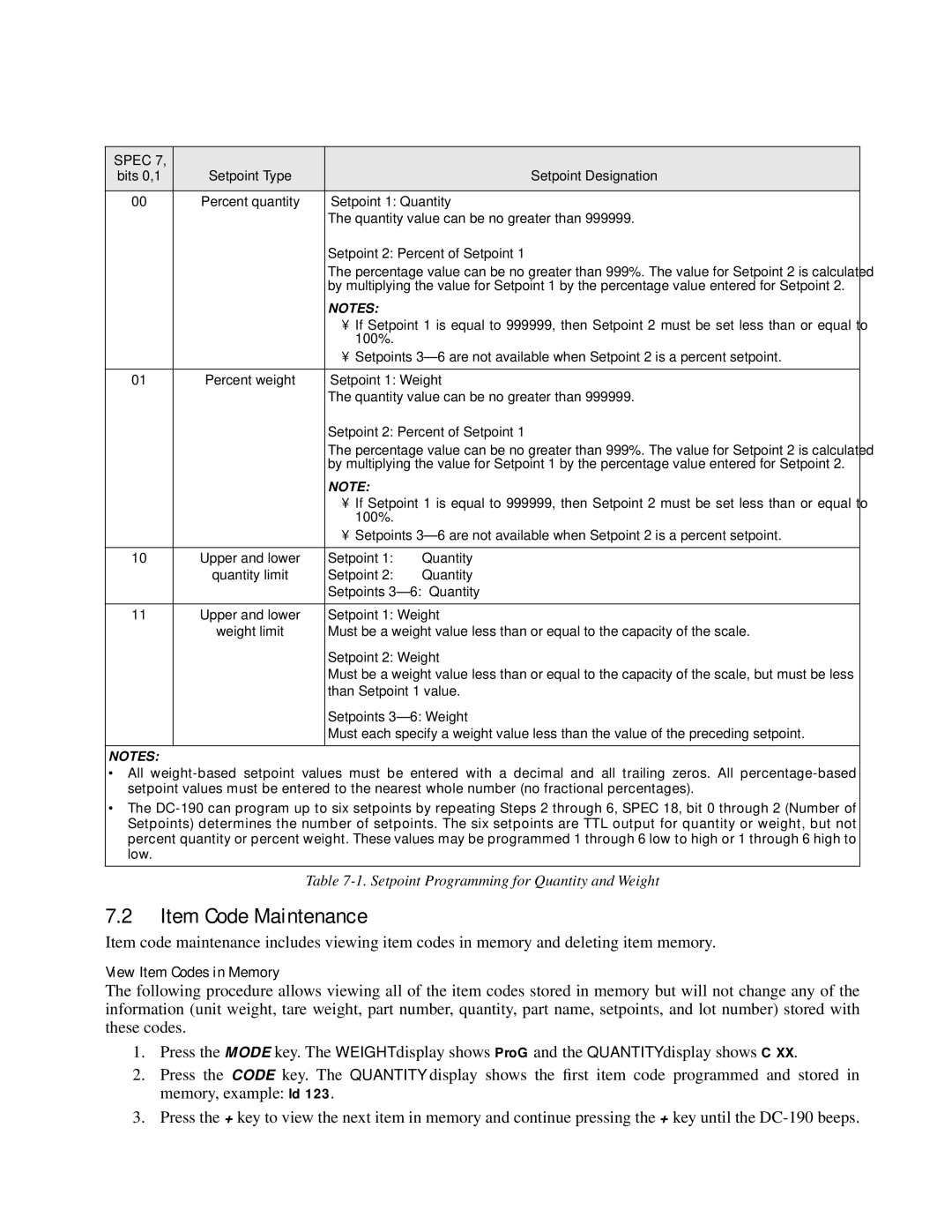

bits 0,1 | Setpoint Type |

| Setpoint Designation |

|

|

| |

00 | Percent quantity | Setpoint 1: Quantity | |

|

| The quantity value can be no greater than 999999. | |

|

| Setpoint 2: Percent of Setpoint 1 | |

|

| The percentage value can be no greater than 999%. The value for Setpoint 2 is calculated | |

|

| by multiplying the value for Setpoint 1 by the percentage value entered for Setpoint 2. | |

|

| NOTES: |

|

|

| • If Setpoint 1 is equal to 999999, then Setpoint 2 must be set less than or equal to | |

|

| 100%. |

|

|

| • Setpoints | |

|

|

| |

01 | Percent weight | Setpoint 1: Weight | |

|

| The quantity value can be no greater than 999999. | |

|

| Setpoint 2: Percent of Setpoint 1 | |

|

| The percentage value can be no greater than 999%. The value for Setpoint 2 is calculated | |

|

| by multiplying the value for Setpoint 1 by the percentage value entered for Setpoint 2. | |

|

| NOTE: |

|

|

| • If Setpoint 1 is equal to 999999, then Setpoint 2 must be set less than or equal to | |

|

| 100%. |

|

|

| • Setpoints | |

|

|

|

|

10 | Upper and lower | Setpoint 1: | Quantity |

| quantity limit | Setpoint 2: | Quantity |

|

| Setpoints | |

|

|

| |

11 | Upper and lower | Setpoint 1: Weight | |

| weight limit | Must be a weight value less than or equal to the capacity of the scale. | |

|

| Setpoint 2: Weight | |

|

| Must be a weight value less than or equal to the capacity of the scale, but must be less | |

|

| than Setpoint 1 value. | |

|

| Setpoints | |

|

| Must each specify a weight value less than the value of the preceding setpoint. | |

|

|

|

|

NOTES:

• All

• The

Table

7.2Item Code Maintenance

Item code maintenance includes viewing item codes in memory and deleting item memory.

View Item Codes in Memory

The following procedure allows viewing all of the item codes stored in memory but will not change any of the information (unit weight, tare weight, part number, quantity, part name, setpoints, and lot number) stored with these codes.

1.Press the MODE key. The WEIGHT display shows ProG and the QUANTITY display shows C XX.

2.Press the CODE key. The QUANTITY display shows the first item code programmed and stored in memory, example: Id 123.

3.Press the + key to view the next item in memory and continue pressing the + key until the