HIGH EFFICIENCY DECATHLON SERIES GAS FRYERS

CHAPTER 1: SERVICE PROCEDURES

1.8.5 Improper Filtration Function (cont.)

Incorrectly sized or installed paper will allow food particles and sediment to pass through and clog the suction tube on the bottom of the filter carriage. Particles large enough to block the suction tube may indicate that the crumb tray is not being used.

Pan blockage can also occur if shortening is left in the pan and allowed to solidify. Heater strips (if equipped) on the oil return plumbing are designed to prevent solidification of shortening left in the plumbing. Heater strips will not melt or prevent solidification of shortening in the pan.

Remove blockage by forcing it out with an auger or drain snake. DO NOT use compressed air or other pressurized gases to force out the blockage.

The SUFF/UFF filtration systems use microswitches attached to handles for each vat. They are wired in parallel and provide the 24 VAC required to activate the pump relay coil when the handles are moved to the ON position. The activated pump relay coil pulls the pump motor switch in, supplying power to the pump motor.

Filter systems equipped with

1.8.6 Frypot Leakage

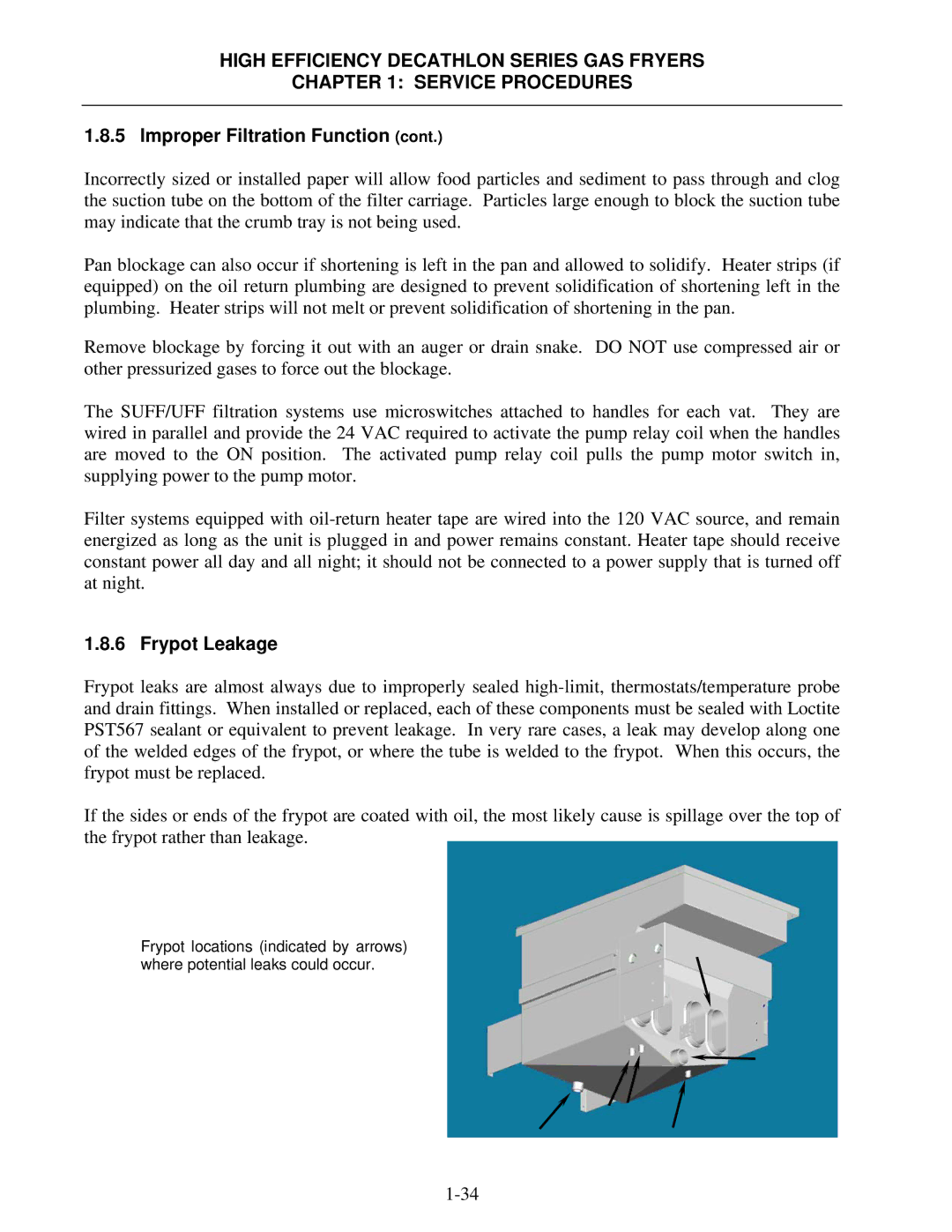

Frypot leaks are almost always due to improperly sealed

If the sides or ends of the frypot are coated with oil, the most likely cause is spillage over the top of the frypot rather than leakage.

Frypot locations (indicated by arrows) where potential leaks could occur.