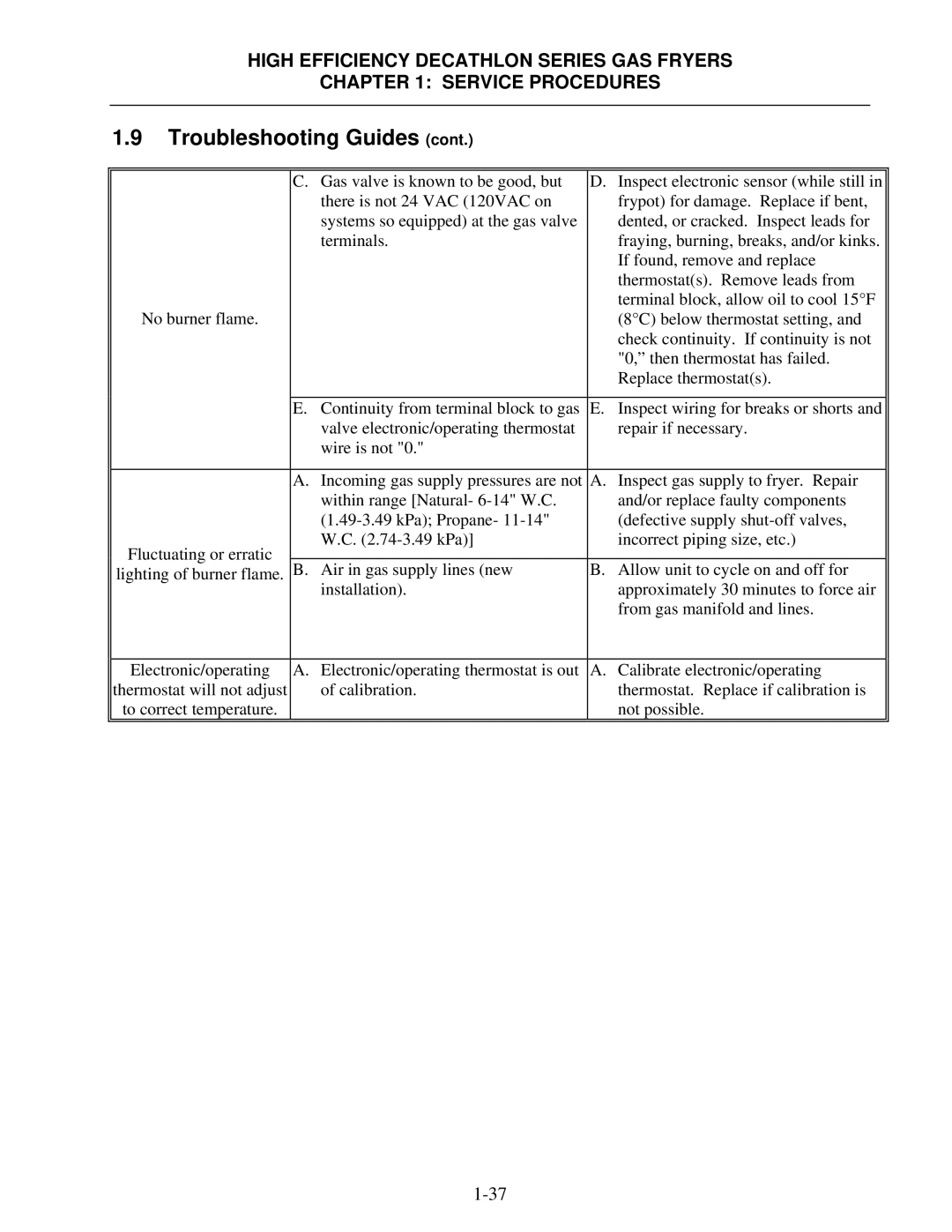

HIGH EFFICIENCY DECATHLON SERIES GAS FRYERS

CHAPTER 1: SERVICE PROCEDURES

1.9Troubleshooting Guides (cont.)

| C. | Gas valve is known to be good, but | D. | Inspect electronic sensor (while still in | |

|

| there is not 24 VAC (120VAC on |

| frypot) for damage. Replace if bent, | |

|

| systems so equipped) at the gas valve |

| dented, or cracked. Inspect leads for | |

|

| terminals. |

| fraying, burning, breaks, and/or kinks. | |

|

|

|

| If found, remove and replace | |

|

|

|

| thermostat(s). Remove leads from | |

No burner flame. |

|

|

| terminal block, allow oil to cool 15°F | |

|

|

| (8°C) below thermostat setting, and | ||

|

|

|

| check continuity. If continuity is not | |

|

|

|

| "0,” then thermostat has failed. | |

|

|

|

| Replace thermostat(s). | |

|

|

|

|

| |

| E. | Continuity from terminal block to gas | E. | Inspect wiring for breaks or shorts and | |

|

| valve electronic/operating thermostat |

| repair if necessary. | |

|

| wire is not "0." |

|

| |

|

|

|

|

| |

| A. | Incoming gas supply pressures are not | A. | Inspect gas supply to fryer. Repair | |

|

| within range [Natural- |

| and/or replace faulty components | |

|

|

| (defective supply | ||

Fluctuating or erratic |

| W.C. |

| incorrect piping size, etc.) | |

|

|

|

| ||

B. | Air in gas supply lines (new | B. | Allow unit to cycle on and off for | ||

lighting of burner flame. | |||||

|

| installation). |

| approximately 30 minutes to force air | |

|

|

|

| from gas manifold and lines. | |

|

|

|

|

| |

Electronic/operating | A. | Electronic/operating thermostat is out | A. | Calibrate electronic/operating | |

thermostat will not adjust |

| of calibration. |

| thermostat. Replace if calibration is | |

to correct temperature. |

|

|

| not possible. | |

|

|

|

|

|