FIELD WIRING CONNECTIONS TO BUSS BARS

500Kw Volvo and 500/600Kw Doosan powered units supplied with Series C - R Frame Breakers rated 1400, 1600, 2000 and 2500A have Buss Bars supplied in the connection Module for the connection of the Field Conductors. The following information should be followed in order to obtain a suitable electrical connec- tion to the Buss Bars.

•Conductor Lugs - The Buss Bars have been configured to accept Aluminum Compression Lugs suitable for copper or aluminum stranded wire .

•Suggested Manufacturer - PENN UNION CORP

•Manufacturers Part No. - BLUA060D2

• | Type - Dual Rated (Al/CU), Two | Studs spaced 1 3/4" Apart |

• | Wire Size - 600 kcmil |

|

Required Hardware

Below is the recommended hardware required to attach the Lugs to the Buss Bars,

•M12 x 65mm Grade 8,8 Hex Head Cap Screw, M12 Flat Washers, Lock Washer and Nut

or

• | Grade SAE 5 Hex Head Cap Screw, | Flat | |

Washers, Lock Washer and Nut |

|

| |

Required Torque - Tighten fasteners to: |

|

| |

M12 | Dry 75 | Lubed 58 FHbs | |

1/2" | Dry 85 FHbs | Lubed 65 FHbs | |

GENERATOR AND LOAD

COMPATIBILITY

The generator must be fully compatible with the rated voltage, phase and frequency of the connected electrical loads. The gen- erator, connected electrical devices, or both, can be damaged if voltage, phase and frequency are not compatible,

NOTE:

This manual assumes that the stationary emergency generator has been properly selected, installed and interconnected by a competent, qualified electrician or installation contractor. Once the installation is complete, do nothing that may result in non- compatibility between the generator and connected electrical loads.

STARTING AIDS

The stationary emergency generator may be equipped with one or more starting aids that serve to provide quicker, easier starts under varying climactic conditions.

This generator may have been mounted with (a) an engine coolant heater, (b) an engine oil heater, (c) a battery warmer or (d) a bat- tery charger. These aids are powered by a normal (utility) power source during nonoperating periods.

General Information

ENGINE COOLANT HEATERS

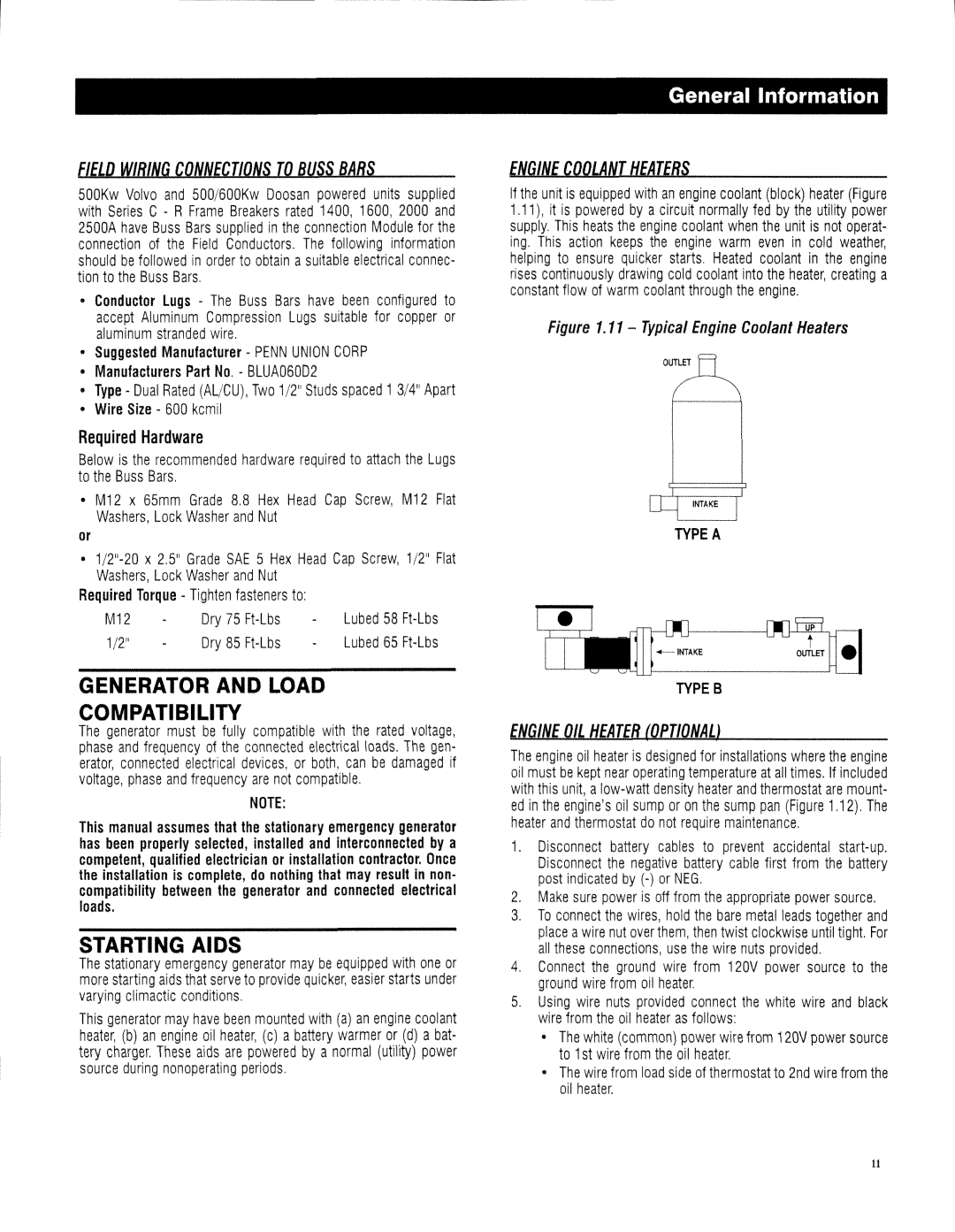

If the unit is equipped with an engine coolant (block) heater (Figure 1.11), it is powered by a circuit normally fed by the utility power supply. This heats the engine coolant when the unit is not operat- ing, This action keeps the engine warm even in cold weather, helping to ensure quicker starts, Heated coolant in the engine rises continuously drawing cold coolant into the heater, creating a constant flow of warm coolant through the engine.

Figure 1.11- Typical Engine Coolant Heaters

OUTLET

TYPE A

TYPES

ENGINE OIL HEATER (OPTIONAL)

The engine oil heater is designed for installations where the engine oil must be kept near operating temperature at all times. If included with this unit,

1.Disconnect battery cables to prevent accidental

2.Make sure power is off from the appropriate power source.

3.To connect the wires, hold the bare metal leads together and place awire nut over them, then twist clockwise until tight. For all these connections, use the wire nuts provided.

4.Connect the ground wire from 120V power source to the ground wire from oil heater,

5.Using wire nuts provided connect the white wire and black wire from the oil heater as follows:

•The white (common) power wire from 120V power source to 1st wire from the oil heater.

•The wire from load side of thermostat to 2nd wire from the oil heater.

11