Always use push sticks, featherboards, push paddles and other safety accessories whenever possible to increase safety and control during operations which require that the blade guard and splitter must be removed from the saw. ALWAYS replace the blade guard after dadoing is complete.

5.Adjust the fence, turn the saw ON, raise the blade into the sacrificial fence to the height needed for the rabbeting operation, and turn the saw OFF.

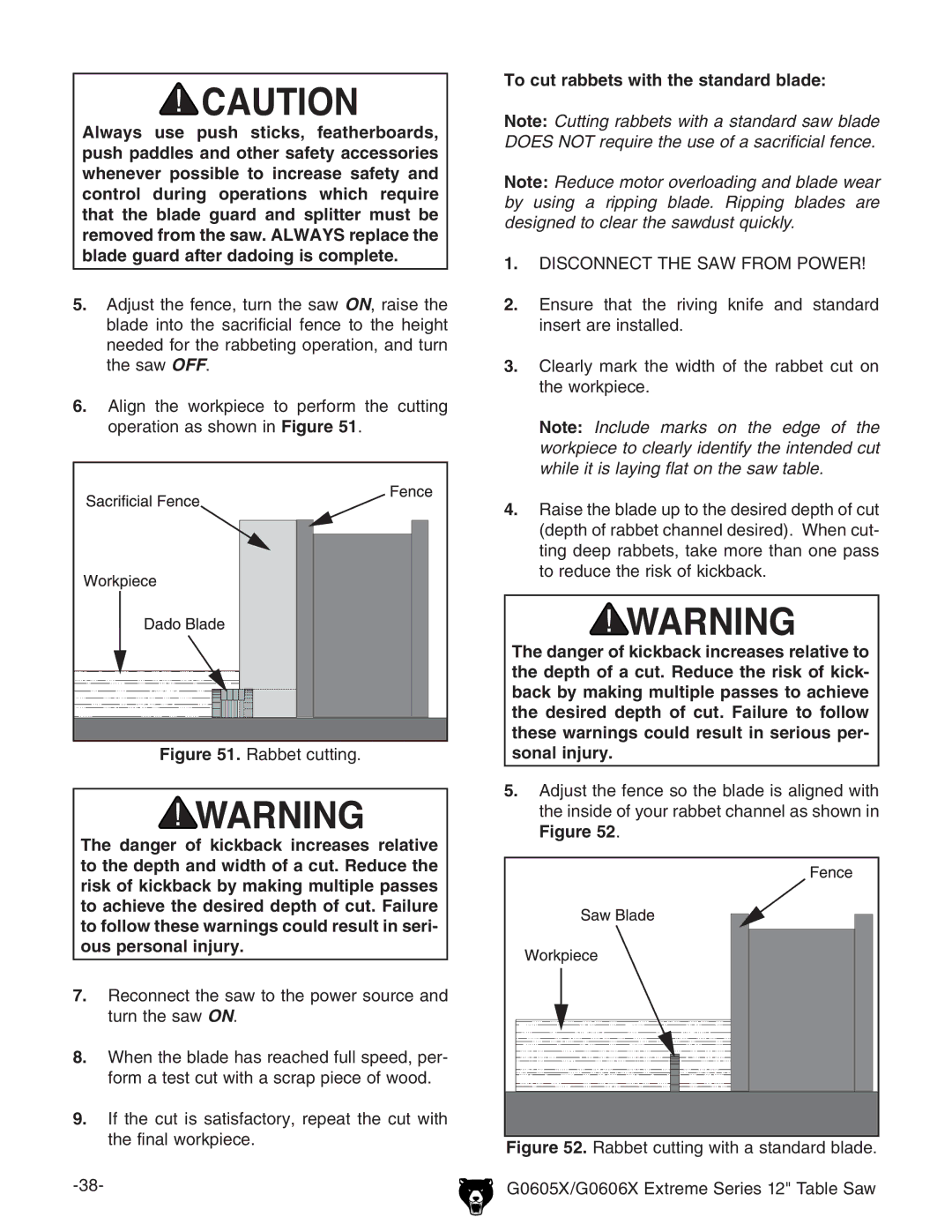

6.Align the workpiece to perform the cutting operation as shown in Figure 51.

Figure 51. Rabbet cutting.

The danger of kickback increases relative to the depth and width of a cut. Reduce the risk of kickback by making multiple passes to achieve the desired depth of cut. Failure to follow these warnings could result in seri- ous personal injury.

7.Reconnect the saw to the power source and turn the saw ON.

8.When the blade has reached full speed, per- form a test cut with a scrap piece of wood.

9.If the cut is satisfactory, repeat the cut with the final workpiece.

To cut rabbets with the standard blade:

Note: Cutting rabbets with a standard saw blade DOES NOT require the use of a sacrificial fence.

Note: Reduce motor overloading and blade wear by using a ripping blade. Ripping blades are designed to clear the sawdust quickly.

1.DISCONNECT THE SAW FROM POWER!

2.Ensure that the riving knife and standard insert are installed.

3.Clearly mark the width of the rabbet cut on the workpiece.

Note: Include marks on the edge of the workpiece to clearly identify the intended cut while it is laying flat on the saw table.

4.Raise the blade up to the desired depth of cut (depth of rabbet channel desired). When cut- ting deep rabbets, take more than one pass to reduce the risk of kickback.

The danger of kickback increases relative to the depth of a cut. Reduce the risk of kick- back by making multiple passes to achieve the desired depth of cut. Failure to follow these warnings could result in serious per- sonal injury.

5.Adjust the fence so the blade is aligned with the inside of your rabbet channel as shown in Figure 52.