Blade Tilt/Bevel Cuts |

| Dado Cutting |

|

|

|

|

|

|

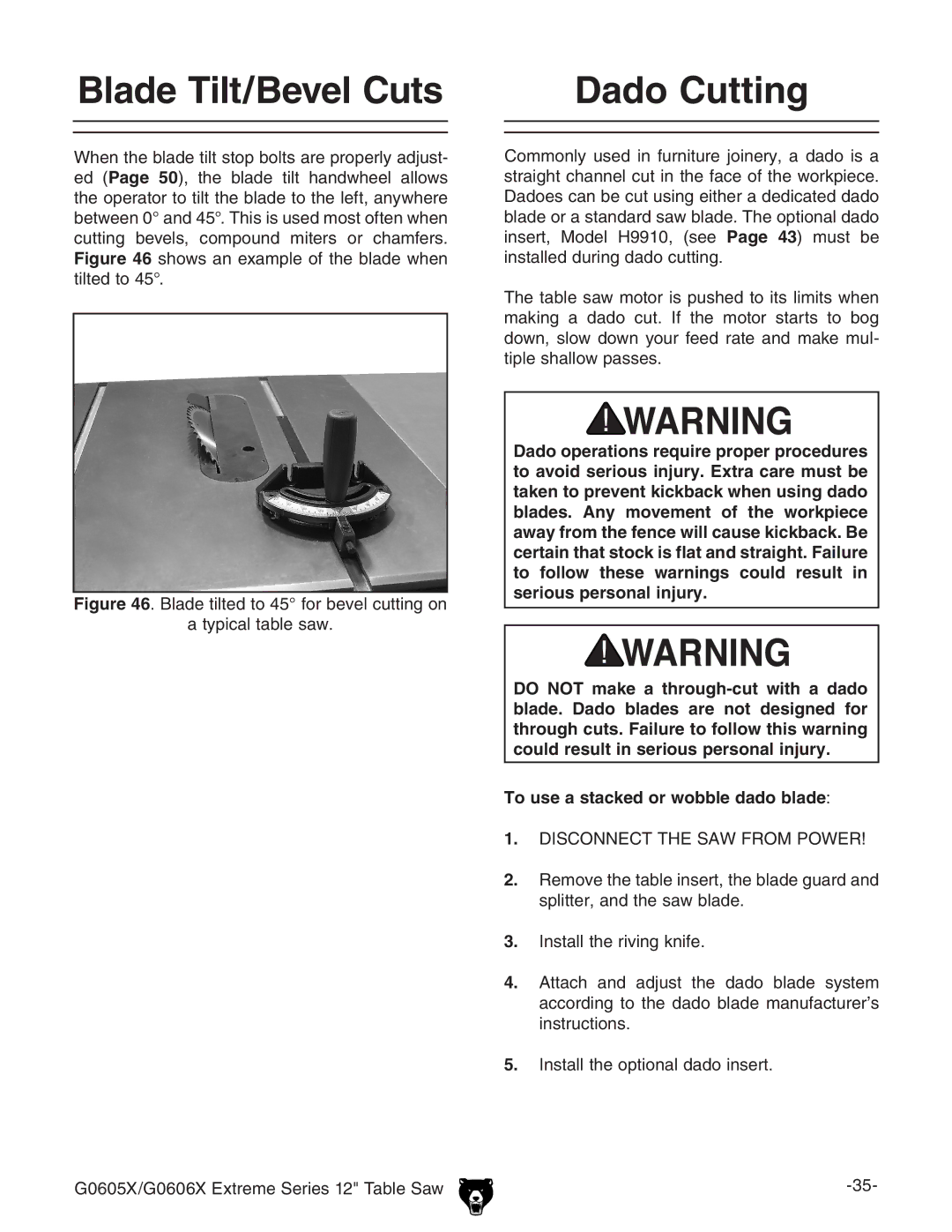

When the blade tilt stop bolts are properly adjust- ed (Page 50), the blade tilt handwheel allows the operator to tilt the blade to the left, anywhere between 0° and 45°. This is used most often when cutting bevels, compound miters or chamfers. Figure 46 shows an example of the blade when tilted to 45°.

Figure 46. Blade tilted to 45° for bevel cutting on

a typical table saw.

G0605X/G0606X Extreme Series 12" Table Saw

Commonly used in furniture joinery, a dado is a straight channel cut in the face of the workpiece. Dadoes can be cut using either a dedicated dado blade or a standard saw blade. The optional dado insert, Model H9910, (see Page 43) must be installed during dado cutting.

The table saw motor is pushed to its limits when making a dado cut. If the motor starts to bog down, slow down your feed rate and make mul- tiple shallow passes.

Dado operations require proper procedures to avoid serious injury. Extra care must be taken to prevent kickback when using dado blades. Any movement of the workpiece away from the fence will cause kickback. Be certain that stock is flat and straight. Failure to follow these warnings could result in serious personal injury.

DO NOT make a

To use a stacked or wobble dado blade:

1.DISCONNECT THE SAW FROM POWER!

2.Remove the table insert, the blade guard and splitter, and the saw blade.

3.Install the riving knife.

4.Attach and adjust the dado blade system according to the dado blade manufacturer’s instructions.

5.Install the optional dado insert.