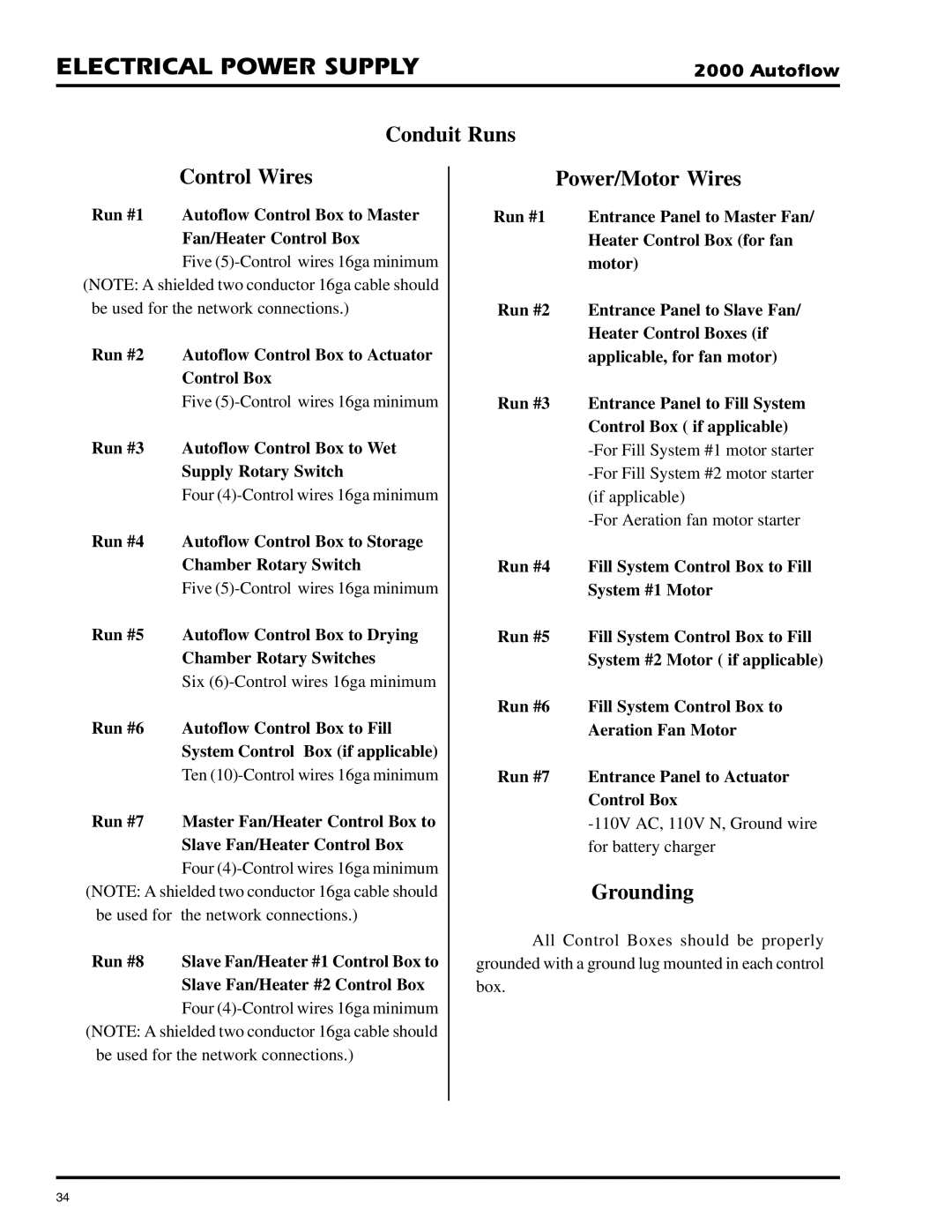

ELECTRICAL POWER SUPPLY

2000 Autoflow

Conduit Runs

Control Wires

Run #1 Autoflow Control Box to Master Fan/Heater Control Box

Five

(NOTE: A shielded two conductor 16ga cable should be used for the network connections.)

Run #2 Autoflow Control Box to Actuator Control Box

Five

Run #3 Autoflow Control Box to Wet Supply Rotary Switch

Four

Run #4 Autoflow Control Box to Storage Chamber Rotary Switch

Five

Run #5 Autoflow Control Box to Drying Chamber Rotary Switches

Six

Run #6 Autoflow Control Box to Fill System Control Box (if applicable)

Ten

Run #7 Master Fan/Heater Control Box to Slave Fan/Heater Control Box

Four

(NOTE: A shielded two conductor 16ga cable should be used for the network connections.)

Run #8 Slave Fan/Heater #1 Control Box to Slave Fan/Heater #2 Control Box

Four

(NOTE: A shielded two conductor 16ga cable should be used for the network connections.)

Power/Motor Wires

Run #1 Entrance Panel to Master Fan/ Heater Control Box (for fan motor)

Run #2 Entrance Panel to Slave Fan/ Heater Control Boxes (if applicable, for fan motor)

Run #3 Entrance Panel to Fill System Control Box ( if applicable)

Run #4 Fill System Control Box to Fill System #1 Motor

Run #5 Fill System Control Box to Fill System #2 Motor ( if applicable)

Run #6 Fill System Control Box to Aeration Fan Motor

Run #7 Entrance Panel to Actuator Control Box

Grounding

All Control Boxes should be properly grounded with a ground lug mounted in each control box.

34