3654 Portable H2/N2 Analyzer - Calibrations | 39 of 66 |

|

|

4.2.3 Calibration In H2 or N2 at Elevated Pressure

The sensor can be calibrated in pure H2 or N2 gas at an elevated pressure. This method requires an accurate pressure gauge connected to the exit of the flow chamber.

WARNING

Handle H2 gas with great care. It is extremely flammable and explosive.

When calibrating in gas phase, the flow chamber and sensor head must be dry.To ensure that the flow chamber and sensor components are dry, remove and dry them with a clean soft tissue.

1)Set the gas measurement phase to Gaseous and set the calibration medium to In a liquid or a gaseous sample at known concentration (as detailed in “Calibration Medium” on page 32).

2)Connect a source of pure H2 or N2 gas to the inlet of the flow chamber, as illustrated in Fig

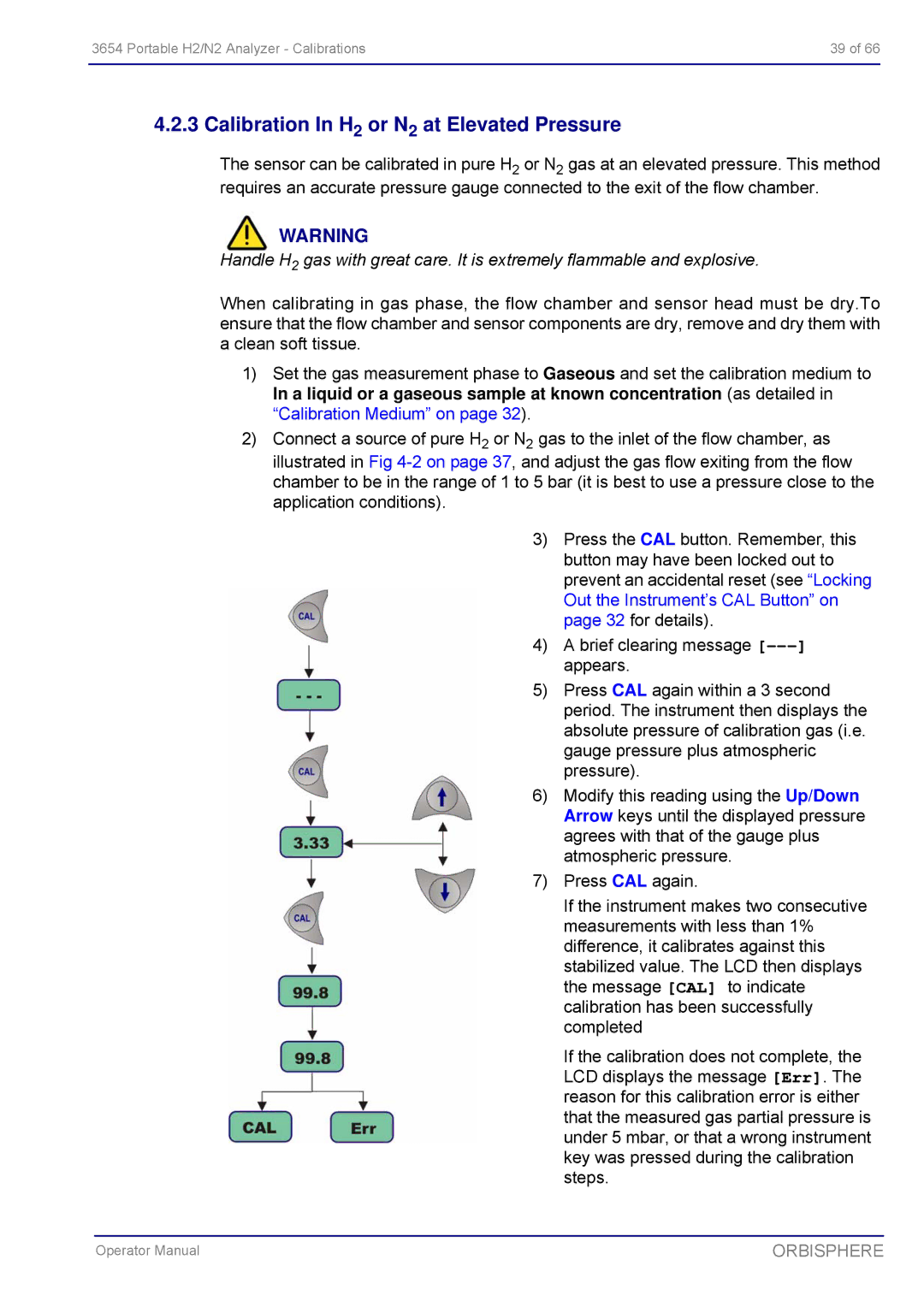

3)Press the CAL button. Remember, this button may have been locked out to prevent an accidental reset (see “Locking Out the Instrument’s CAL Button” on page 32 for details).

4)A brief clearing message

5)Press CAL again within a 3 second period. The instrument then displays the absolute pressure of calibration gas (i.e. gauge pressure plus atmospheric pressure).

6)Modify this reading using the Up/Down Arrow keys until the displayed pressure agrees with that of the gauge plus atmospheric pressure.

7)Press CAL again.

If the instrument makes two consecutive measurements with less than 1% difference, it calibrates against this stabilized value. The LCD then displays the message [CAL] to indicate calibration has been successfully completed

If the calibration does not complete, the LCD displays the message [Err]. The reason for this calibration error is either that the measured gas partial pressure is under 5 mbar, or that a wrong instrument key was pressed during the calibration steps.

Operator Manual | ORBISPHERE |