44 of 66 | Maintenance and Troubleshooting - 3654 Portable H2/N2 Analyzer |

|

|

6.2.3 Mounting Dual Membranes

In order to prevent unwanted stretching of the membrane on a hydrogen sensor it is recommended to simultaneously mount a support membrane beneath the primary membrane.

The primary membrane, or top membrane, determines the rate at which the H2 gas enters the measurement chamber of the sensor. The secondary membrane, or support membrane on the bottom, is extremely permeable and is installed to stabilize the position of the primary membrane.

Two primary membrane types are used for H2 measurement depending on the type of application:

•29561A - used for waste gas, off gas and dH2 in a boiling water reactor

•2952A - used for dH2 in reactor cooling systems of a pressurized water reactor.

The support or secondary membrane for all H2 measurement applications is the 29562A.

As two membranes will be mounted together, the mounting ring used must be part number 29229 which is designed for a thickness of 50 microns or more. Mounting ring part number 29228 is designed for a single membrane and should not be used for mounting dual membranes.

6.3Membrane Replacement

Note:

After replacing a membrane, the sensor must always be

6.3.1 Removing the Membrane

It is recommended to leave the sensor in place in the instrument when changing the membrane. It is not necessary to remove it.

To remove the membrane, follow the steps below:

First remove the flow chamber from the sensor by turning the flow chamber locking pin (see position in Fig

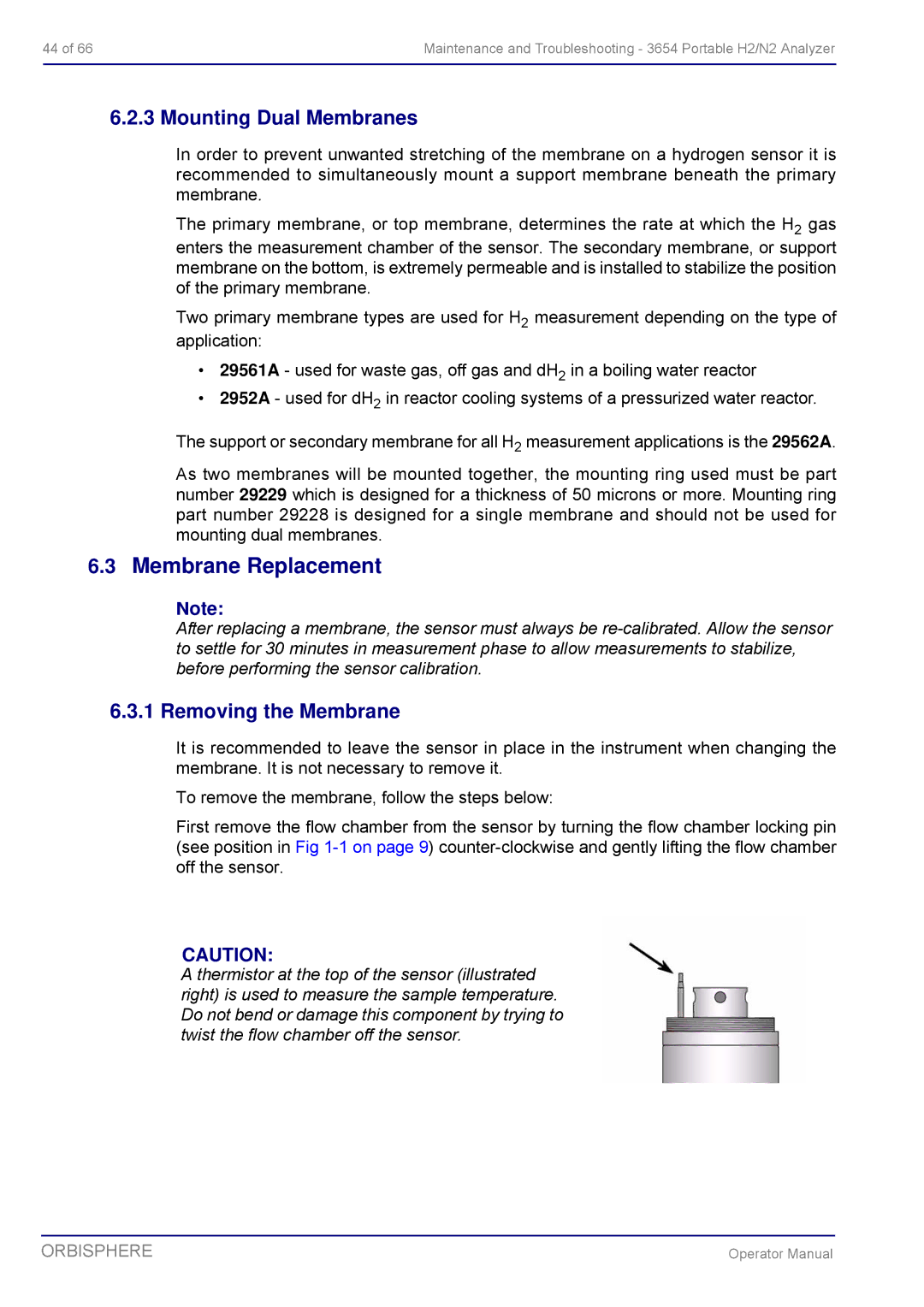

CAUTION:

A thermistor at the top of the sensor (illustrated right) is used to measure the sample temperature. Do not bend or damage this component by trying to twist the flow chamber off the sensor.

ORBISPHERE | Operator Manual |