Shock Load Output Torque

The nominal output torque (TN) is the actual working torque the Planetary Gearbox will generate. The shock load output torque (TAB) is the additional torque that can be generated by starting and stopping with no acceleration ramps, payloads, inertia and directional changes. Although the nominal output torque (TN) of the Planetary Gearbox is accurately calculated, shock loads can greatly increase the dy- namic torque on the Planetary Gearbox.

Each Planetary Gearbox has a maximum specified output torque. In this example a 7:1 single stage MD23 Planetary Gearbox is being used. The maximum specified output torque is 566

When calculating the shock load output torque (TAB), the calculated nominal output torque (TN) and the operating factor (CB) are taken into account. CB is merely a factor which addresses the different working conditions of a Planetary Gearbox and is the result of your subjective appraisal. It is therefore only meant as a guide value. The following factors are included in the approximate estimation of the operating factor (CB):

Direction of rotation (constant or alternating)

Load (shocks)

Daily operating time

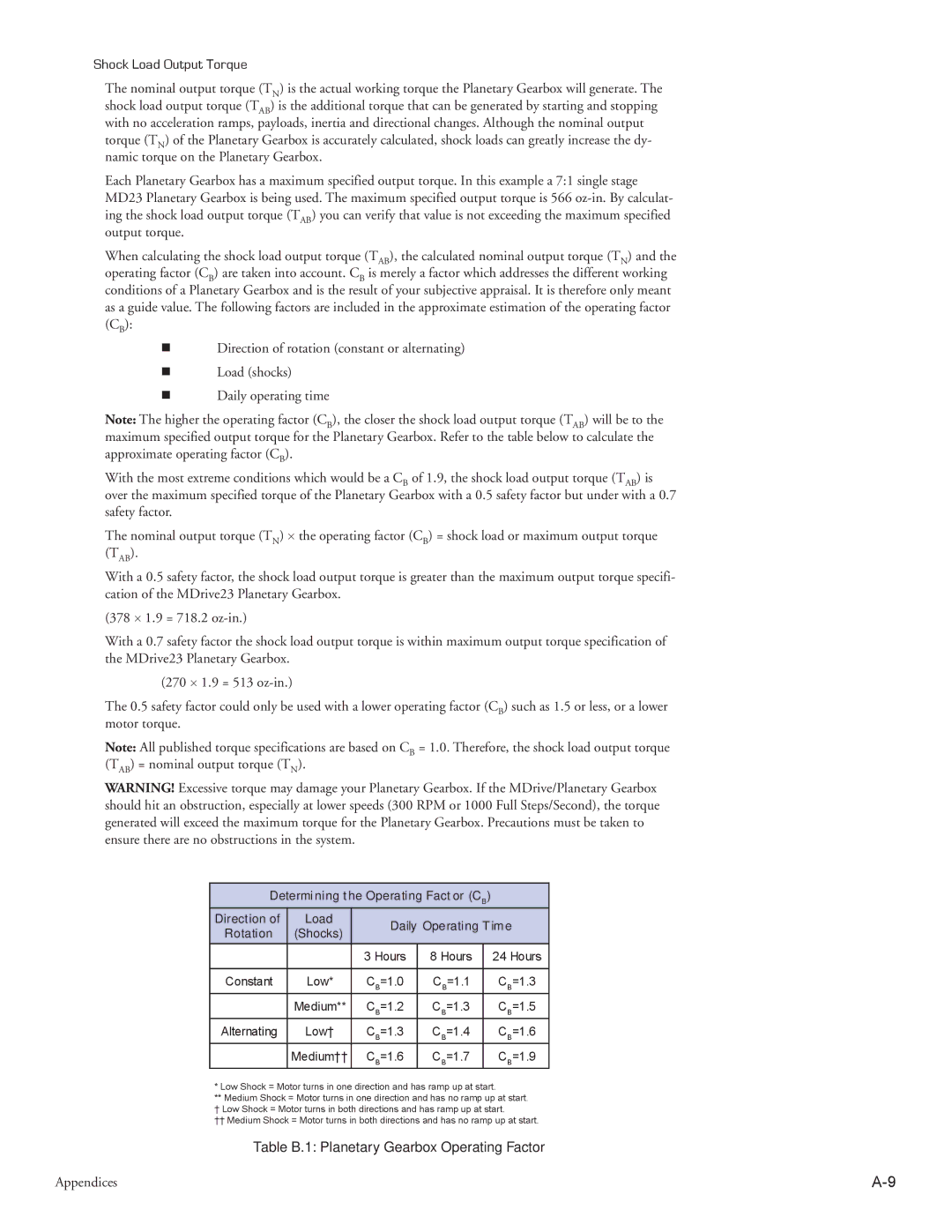

Note: The higher the operating factor (CB), the closer the shock load output torque (TAB) will be to the maximum specified output torque for the Planetary Gearbox. Refer to the table below to calculate the approximate operating factor (CB).

With the most extreme conditions which would be a CB of 1.9, the shock load output torque (TAB) is over the maximum specified torque of the Planetary Gearbox with a 0.5 safety factor but under with a 0.7 safety factor.

The nominal output torque (TN) ⋅ the operating factor (CB) = shock load or maximum output torque (TAB).

With a 0.5 safety factor, the shock load output torque is greater than the maximum output torque specifi- cation of the MDrive23 Planetary Gearbox.

(378 ⋅ 1.9 = 718.2

With a 0.7 safety factor the shock load output torque is within maximum output torque specification of the MDrive23 Planetary Gearbox.

(270 ⋅ 1.9 = 513

The 0.5 safety factor could only be used with a lower operating factor (CB) such as 1.5 or less, or a lower motor torque.

Note: All published torque specifications are based on CB = 1.0. Therefore, the shock load output torque (TAB) = nominal output torque (TN).

WARNING! Excessive torque may damage your Planetary Gearbox. If the MDrive/Planetary Gearbox should hit an obstruction, especially at lower speeds (300 RPM or 1000 Full Steps/Second), the torque generated will exceed the maximum torque for the Planetary Gearbox. Precautions must be taken to ensure there are no obstructions in the system.

Determining the Operating Factor (CB)

Direction of | Load | Daily Operating Time | |||

Rotation | (Shocks) | ||||

|

|

| |||

|

| 3 Hours | 8 Hours | 24 Hours | |

|

|

|

|

| |

Constant | Low* | CB=1.0 | CB=1.1 | CB=1.3 | |

| Medium** | CB=1.2 | CB=1.3 | CB=1.5 | |

Alternating | Low† | CB=1.3 | CB=1.4 | CB=1.6 | |

| Medium†† | CB=1.6 | CB=1.7 | CB=1.9 | |

*Low Shock = Motor turns in one direction and has ramp up at start.

**Medium Shock = Motor turns in one direction and has no ramp up at start.

† Low Shock = Motor turns in both directions and has ramp up at start.

†† Medium Shock = Motor turns in both directions and has no ramp up at start.

Table B.1: Planetary Gearbox Operating Factor

Appendices |