SAFETY INSPECTION | SECTION 2 |

Section 2 - Safety Inspection includes the following:

Safety Inspection Checklist |

|

Troubleshooting | Maintenance |

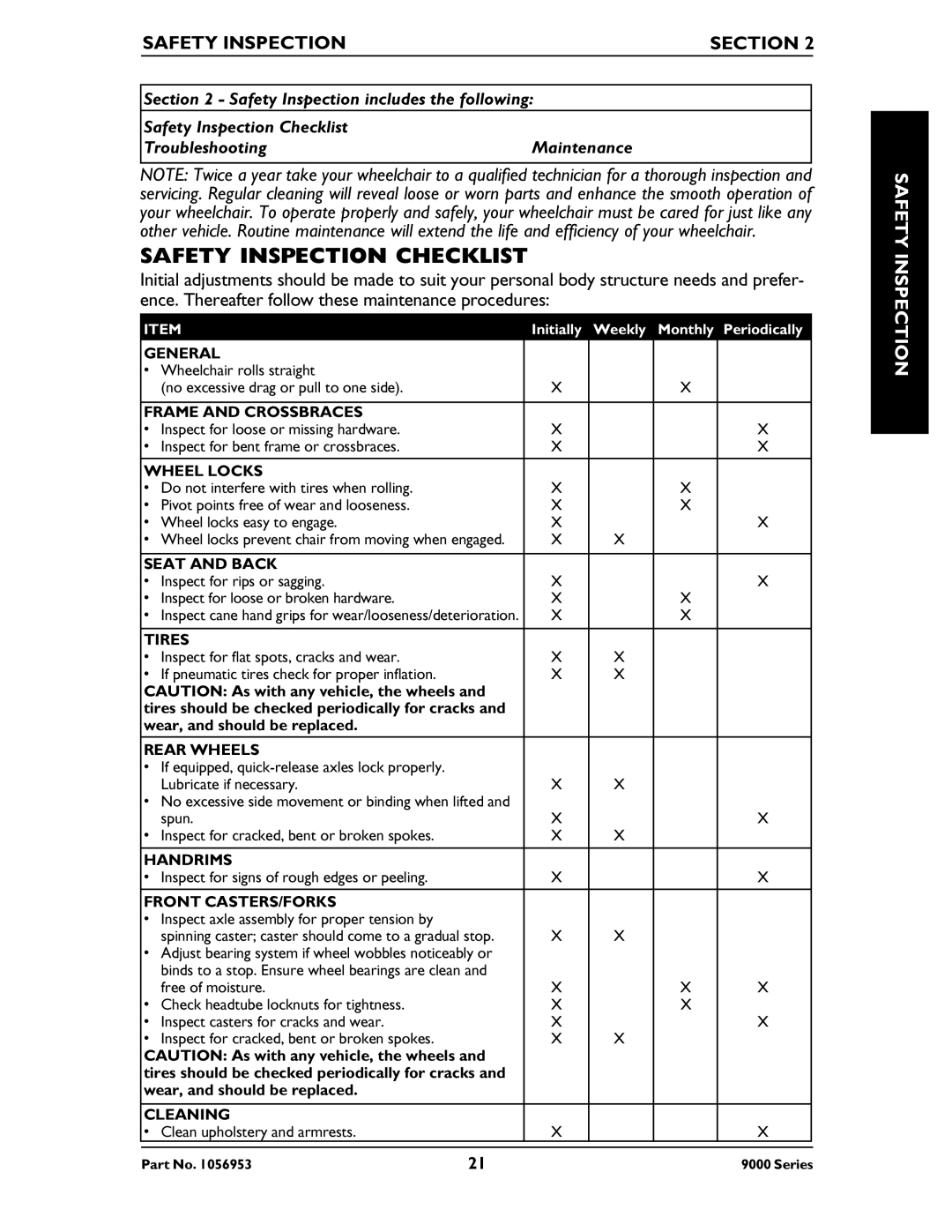

NOTE: Twice a year take your wheelchair to a qualified technician for a thorough inspection and servicing. Regular cleaning will reveal loose or worn parts and enhance the smooth operation of your wheelchair. To operate properly and safely, your wheelchair must be cared for just like any other vehicle. Routine maintenance will extend the life and efficiency of your wheelchair.

SAFETY INSPECTION CHECKLIST

Initial adjustments should be made to suit your personal body structure needs and prefer- ence. Thereafter follow these maintenance procedures:

ITEM | Initially | Weekly | Monthly | Periodically |

GENERAL |

|

|

|

|

• Wheelchair rolls straight |

|

|

|

|

(no excessive drag or pull to one side). | X |

| X |

|

|

|

|

|

|

FRAME AND CROSSBRACES |

|

|

|

|

• Inspect for loose or missing hardware. | X |

|

| X |

• Inspect for bent frame or crossbraces. | X |

|

| X |

|

|

|

|

|

WHEEL LOCKS |

|

|

|

|

• Do not interfere with tires when rolling. | X |

| X |

|

• Pivot points free of wear and looseness. | X |

| X |

|

• Wheel locks easy to engage. | X |

|

| X |

• Wheel locks prevent chair from moving when engaged. | X | X |

|

|

|

|

|

|

|

SEAT AND BACK |

|

|

|

|

• Inspect for rips or sagging. | X |

|

| X |

• Inspect for loose or broken hardware. | X |

| X |

|

• Inspect cane hand grips for wear/looseness/deterioration. | X |

| X |

|

|

|

|

|

|

TIRES |

|

|

|

|

• Inspect for flat spots, cracks and wear. | X | X |

|

|

• If pneumatic tires check for proper inflation. | X | X |

|

|

CAUTION: As with any vehicle, the wheels and |

|

|

|

|

tires should be checked periodically for cracks and |

|

|

|

|

wear, and should be replaced. |

|

|

|

|

REAR WHEELS |

|

|

|

|

• If equipped, |

|

|

|

|

Lubricate if necessary. | X | X |

|

|

• No excessive side movement or binding when lifted and |

|

|

|

|

spun. | X |

|

| X |

• Inspect for cracked, bent or broken spokes. | X | X |

|

|

|

|

|

|

|

HANDRIMS |

|

|

|

|

• Inspect for signs of rough edges or peeling. | X |

|

| X |

|

|

|

|

|

FRONT CASTERS/FORKS |

|

|

|

|

• Inspect axle assembly for proper tension by |

|

|

|

|

spinning caster; caster should come to a gradual stop. | X | X |

|

|

• Adjust bearing system if wheel wobbles noticeably or |

|

|

|

|

binds to a stop. Ensure wheel bearings are clean and |

|

|

|

|

free of moisture. | X |

| X | X |

• Check headtube locknuts for tightness. | X |

| X |

|

• Inspect casters for cracks and wear. | X |

|

| X |

• Inspect for cracked, bent or broken spokes. | X | X |

|

|

CAUTION: As with any vehicle, the wheels and |

|

|

|

|

tires should be checked periodically for cracks and |

|

|

|

|

wear, and should be replaced. |

|

|

|

|

|

|

|

|

|

CLEANING |

|

|

|

|

• Clean upholstery and armrests. | X |

|

| X |

|

|

|

|

|

SAFETY INSPECTION

Part No. 1056953 | 21 | 9000 Series |