S A F E T Y

I

N S P E C T I O N

T R O U B L E S H O O T I N G

M A I N T E N A N C E

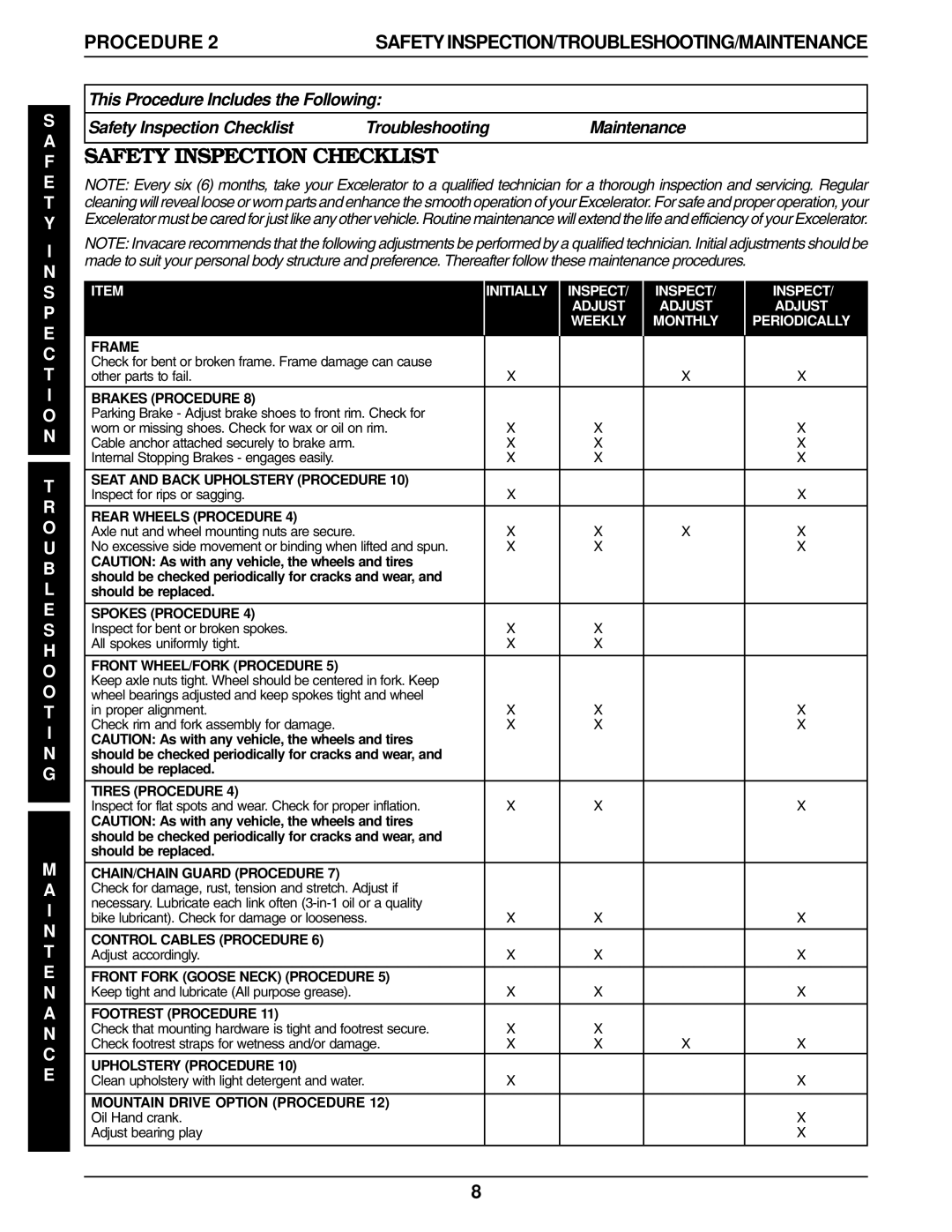

PROCEDURE 2 | SAFETY INSPECTION/TROUBLESHOOTING/MAINTENANCE | |

|

| |

This Procedure Includes the Following: |

| |

|

|

|

Safety Inspection Checklist | Troubleshooting | Maintenance |

|

|

|

SAFETY INSPECTION CHECKLIST

NOTE: Every six (6) months, take your Excelerator to a qualified technician for a thorough inspection and servicing. Regular cleaning will reveal loose or worn parts and enhance the smooth operation of your Excelerator. For safe and proper operation, your Excelerator must be cared for just like any other vehicle. Routine maintenance will extend the life and efficiency of your Excelerator.

NOTE: Invacare recommends that the following adjustments be performed by a qualified technician. Initial adjustments should be made to suit your personal body structure and preference. Thereafter follow these maintenance procedures.

ITEM | INITIALLY | INSPECT/ | INSPECT/ | INSPECT/ |

|

| ADJUST | ADJUST | ADJUST |

|

| WEEKLY | MONTHLY | PERIODICALLY |

|

|

|

|

|

FRAME |

|

|

|

|

Check for bent or broken frame. Frame damage can cause |

|

|

|

|

other parts to fail. | X |

| X | X |

BRAKES (PROCEDURE 8) |

|

|

|

|

Parking Brake - Adjust brake shoes to front rim. Check for |

|

|

|

|

worn or missing shoes. Check for wax or oil on rim. | X | X |

| X |

Cable anchor attached securely to brake arm. | X | X |

| X |

Internal Stopping Brakes - engages easily. | X | X |

| X |

|

|

|

|

|

SEAT AND BACK UPHOLSTERY (PROCEDURE 10) |

|

|

|

|

Inspect for rips or sagging. | X |

|

| X |

|

|

|

|

|

REAR WHEELS (PROCEDURE 4) |

|

|

|

|

Axle nut and wheel mounting nuts are secure. | X | X | X | X |

No excessive side movement or binding when lifted and spun. | X | X |

| X |

CAUTION: As with any vehicle, the wheels and tires |

|

|

|

|

should be checked periodically for cracks and wear, and |

|

|

|

|

should be replaced. |

|

|

|

|

|

|

|

|

|

SPOKES (PROCEDURE 4) |

|

|

|

|

Inspect for bent or broken spokes. | X | X |

|

|

All spokes uniformly tight. | X | X |

|

|

|

|

|

|

|

FRONT WHEEL/FORK (PROCEDURE 5) |

|

|

|

|

Keep axle nuts tight. Wheel should be centered in fork. Keep |

|

|

|

|

wheel bearings adjusted and keep spokes tight and wheel |

|

|

|

|

in proper alignment. | X | X |

| X |

Check rim and fork assembly for damage. | X | X |

| X |

CAUTION: As with any vehicle, the wheels and tires |

|

|

|

|

should be checked periodically for cracks and wear, and |

|

|

|

|

should be replaced. |

|

|

|

|

|

|

|

|

|

TIRES (PROCEDURE 4) |

|

|

|

|

Inspect for flat spots and wear. Check for proper inflation. | X | X |

| X |

CAUTION: As with any vehicle, the wheels and tires |

|

|

|

|

should be checked periodically for cracks and wear, and |

|

|

|

|

should be replaced. |

|

|

|

|

|

|

|

|

|

CHAIN/CHAIN GUARD (PROCEDURE 7) |

|

|

|

|

Check for damage, rust, tension and stretch. Adjust if |

|

|

|

|

necessary. Lubricate each link often |

|

|

|

|

bike lubricant). Check for damage or looseness. | X | X |

| X |

|

|

|

|

|

CONTROL CABLES (PROCEDURE 6) |

|

|

|

|

Adjust accordingly. | X | X |

| X |

|

|

|

|

|

FRONT FORK (GOOSE NECK) (PROCEDURE 5) |

|

|

|

|

Keep tight and lubricate (All purpose grease). | X | X |

| X |

|

|

|

|

|

FOOTREST (PROCEDURE 11) |

|

|

|

|

Check that mounting hardware is tight and footrest secure. | X | X |

|

|

Check footrest straps for wetness and/or damage. | X | X | X | X |

UPHOLSTERY (PROCEDURE 10) |

|

|

|

|

Clean upholstery with light detergent and water. | X |

|

| X |

|

|

|

|

|

MOUNTAIN DRIVE OPTION (PROCEDURE 12) |

|

|

|

|

Oil Hand crank. |

|

|

| X |

Adjust bearing play |

|

|

| X |

|

|

|

|

|

8