SM | Service Manual |

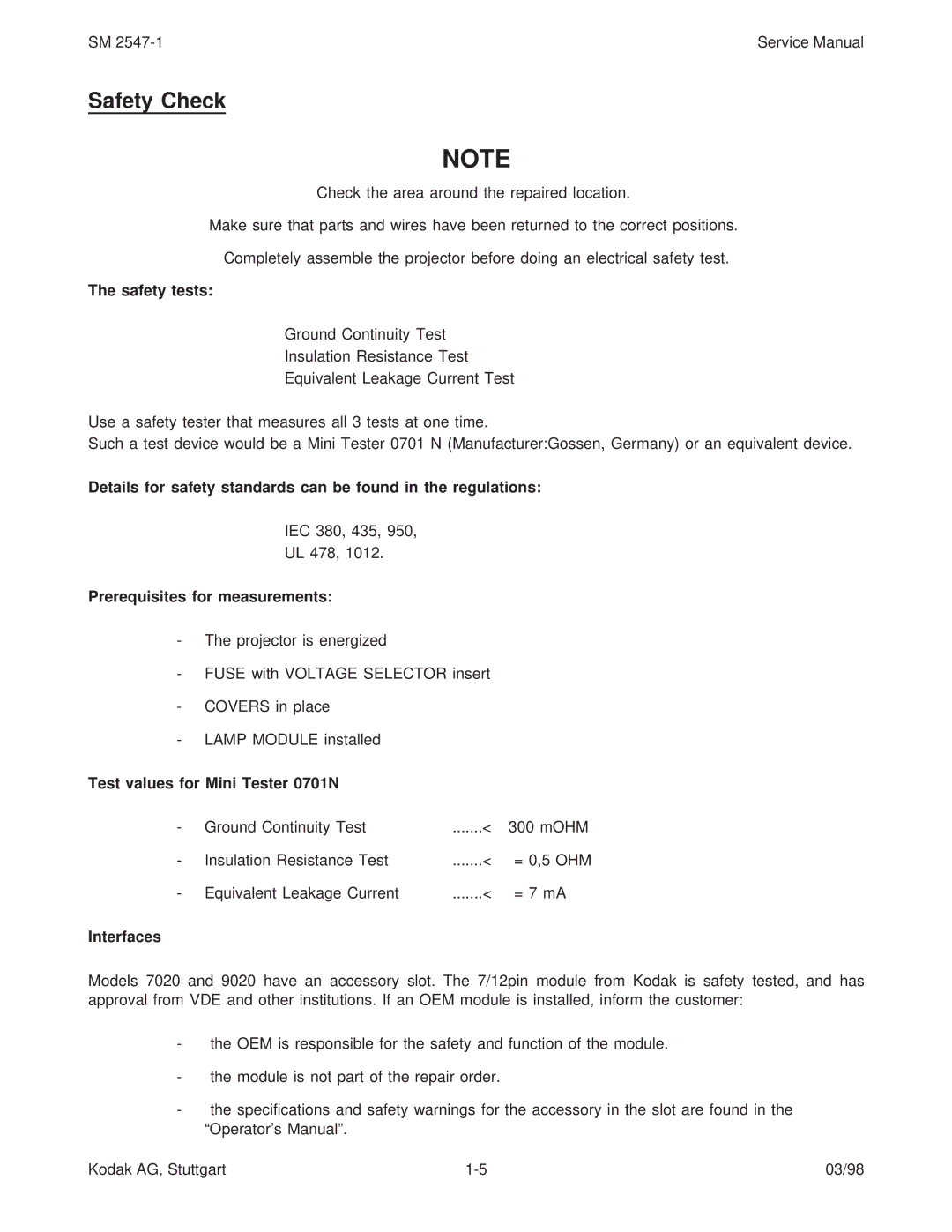

Safety Check

NOTE

Check the area around the repaired location.

Make sure that parts and wires have been returned to the correct positions.

Completely assemble the projector before doing an electrical safety test.

The safety tests:

Ground Continuity Test

Insulation Resistance Test

Equivalent Leakage Current Test

Use a safety tester that measures all 3 tests at one time.

Such a test device would be a Mini Tester 0701 N (Manufacturer:Gossen, Germany) or an equivalent device.

Details for safety standards can be found in the regulations:

IEC 380, 435, 950,

UL 478, 1012.

Prerequisites for measurements:

-The projector is energized

-FUSE with VOLTAGE SELECTOR insert

-COVERS in place

-LAMP MODULE installed

Test values for Mini Tester 0701N

- | Ground Continuity Test | .......< | 300 mOHM |

- | Insulation Resistance Test | .......< | = 0,5 OHM |

- | Equivalent Leakage Current | .......< | = 7 mA |

Interfaces

Models 7020 and 9020 have an accessory slot. The 7/12pin module from Kodak is safety tested, and has approval from VDE and other institutions. If an OEM module is installed, inform the customer:

-the OEM is responsible for the safety and function of the module.

-the module is not part of the repair order.

-the specifications and safety warnings for the accessory in the slot are found in the “Operator’s Manual”.

Kodak AG, Stuttgart | 03/98 |