| OPERATION |

Return to Section TOC

GENERAL DESCRIPTION

The

The

●Reversible, dual groove drive roll. Drive roll will

●Accommodates both 8” (200 mm) diameter and 4” (100 mm) diameter spools of wire.

●No external shielding gas is required when used with Lincoln Innershield .035” (0,9 mm)

●Easy to change polarity.

WELDING CAPABILITY

The

Return to Section TOC

TOC

Return to Master TOC

Return to Master TOC

TOC

RECOMMENDED PROCESSES

The

OPERATIONAL FEATURES AND CONTROLS

The

LIMITATIONS

Arc Gouging cannot be performed with the

CONTROLS AND SETTINGS

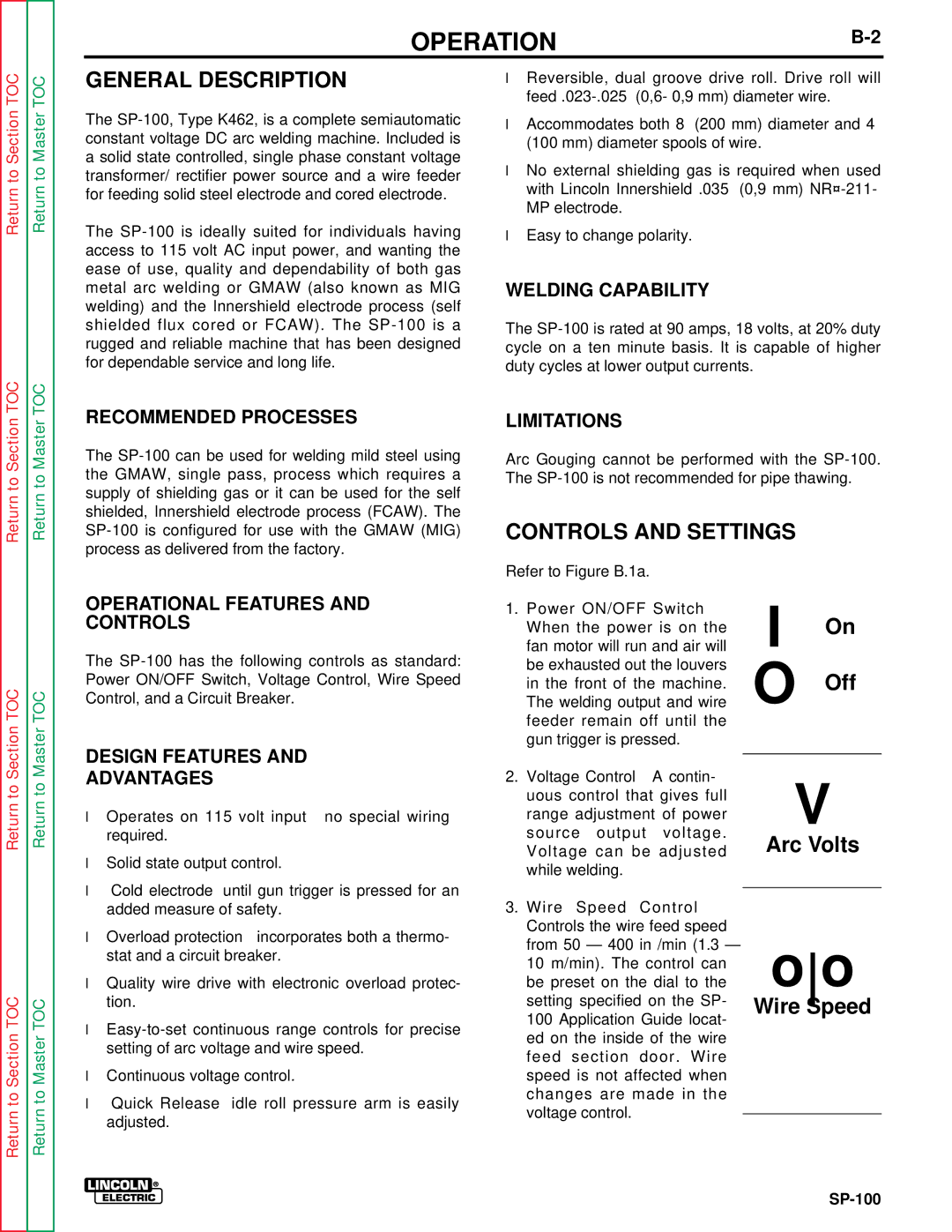

Refer to Figure B.1a. |

|

|

1. Power ON/OFF Switch — | I | On |

When the power is on the | ||

fan motor will run and air will | ||

be exhausted out the louvers | O Off | |

in the front of the machine. | ||

The welding output and wire | ||

feeder remain off until the gun trigger is pressed.

Return to Section

Return to Section TOC

Return to Master

Return to Master TOC

DESIGN FEATURES AND

ADVANTAGES

●Operates on 115 volt input — no special wiring required.

●Solid state output control.

●“Cold electrode” until gun trigger is pressed for an added measure of safety.

●Overload protection — incorporates both a thermo- stat and a circuit breaker.

●Quality wire drive with electronic overload protec- tion.

●

●Continuous voltage control.

●“Quick Release” idle roll pressure arm is easily adjusted.

2.Voltage Control — A contin- uous control that gives full range adjustment of power source output voltage. Voltage can be adjusted while welding.

3.Wire Speed Control — Controls the wire feed speed from 50 – 400 in /min (1.3 – 10 m/min). The control can be preset on the dial to the setting specified on the SP- 100 Application Guide locat- ed on the inside of the wire feed section door. Wire speed is not affected when changes are made in the voltage control.

V

Arc Volts

oo

Wire Speed