Return to Section TOC

Return to Master TOC

| OPERATION |

| |

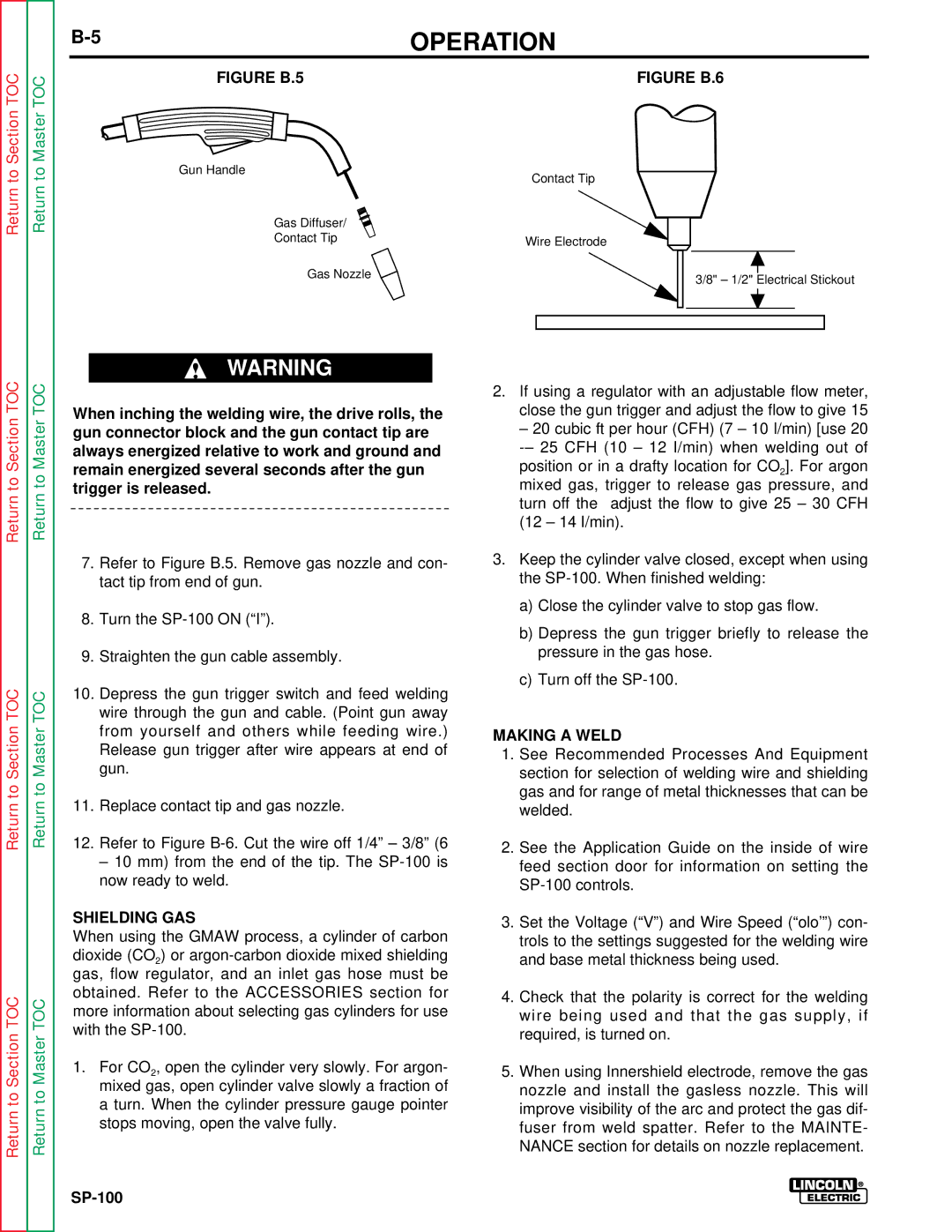

FIGURE B.5 | FIGURE B.6 | ||

Gun Handle

Contact Tip

Gas Diffuser/ |

|

Contact Tip | Wire Electrode |

|

Gas Nozzle | 3/8" – 1/2" Electrical Stickout |

|

Return to Section TOC

Return to Section TOC

Return to Section TOC

Return to Master TOC

Return to Master TOC

Return to Master TOC

WARNING

When inching the welding wire, the drive rolls, the gun connector block and the gun contact tip are always energized relative to work and ground and remain energized several seconds after the gun trigger is released.

7.Refer to Figure B.5. Remove gas nozzle and con- tact tip from end of gun.

8.Turn the

9.Straighten the gun cable assembly.

10.Depress the gun trigger switch and feed welding wire through the gun and cable. (Point gun away from yourself and others while feeding wire.) Release gun trigger after wire appears at end of gun.

11.Replace contact tip and gas nozzle.

12.Refer to Figure

– 10 mm) from the end of the tip. The

SHIELDING GAS

When using the GMAW process, a cylinder of carbon dioxide (CO2) or

1.For CO2, open the cylinder very slowly. For argon- mixed gas, open cylinder valve slowly a fraction of a turn. When the cylinder pressure gauge pointer stops moving, open the valve fully.

2.If using a regulator with an adjustable flow meter, close the gun trigger and adjust the flow to give 15

– 20 cubic ft per hour (CFH) (7 – 10 I/min) [use 20

position or in a drafty location for CO2]. For argon mixed gas, trigger to release gas pressure, and turn off the adjust the flow to give 25 – 30 CFH (12 – 14 I/min).

3.Keep the cylinder valve closed, except when using the

a) Close the cylinder valve to stop gas flow.

b) Depress the gun trigger briefly to release the pressure in the gas hose.

c) Turn off the

MAKING A WELD

1.See Recommended Processes And Equipment section for selection of welding wire and shielding gas and for range of metal thicknesses that can be welded.

2.See the Application Guide on the inside of wire feed section door for information on setting the

3.Set the Voltage (“V”) and Wire Speed (“olo’”) con- trols to the settings suggested for the welding wire and base metal thickness being used.

4.Check that the polarity is correct for the welding wire being used and that the gas supply, if required, is turned on.

5.When using Innershield electrode, remove the gas nozzle and install the gasless nozzle. This will improve visibility of the arc and protect the gas dif- fuser from weld spatter. Refer to the MAINTE- NANCE section for details on nozzle replacement.