Return to Section TOC

Return to Master TOC

|

|

|

| OPERATION |

| ||

|

| FIGURE B.2 |

| WIRE THREADING |

|

| |

|

|

|

|

| Refer to Figure |

|

|

|

|

| 8” Wire Spool |

|

| ||

| Wire Spool Spindle |

|

|

| |||

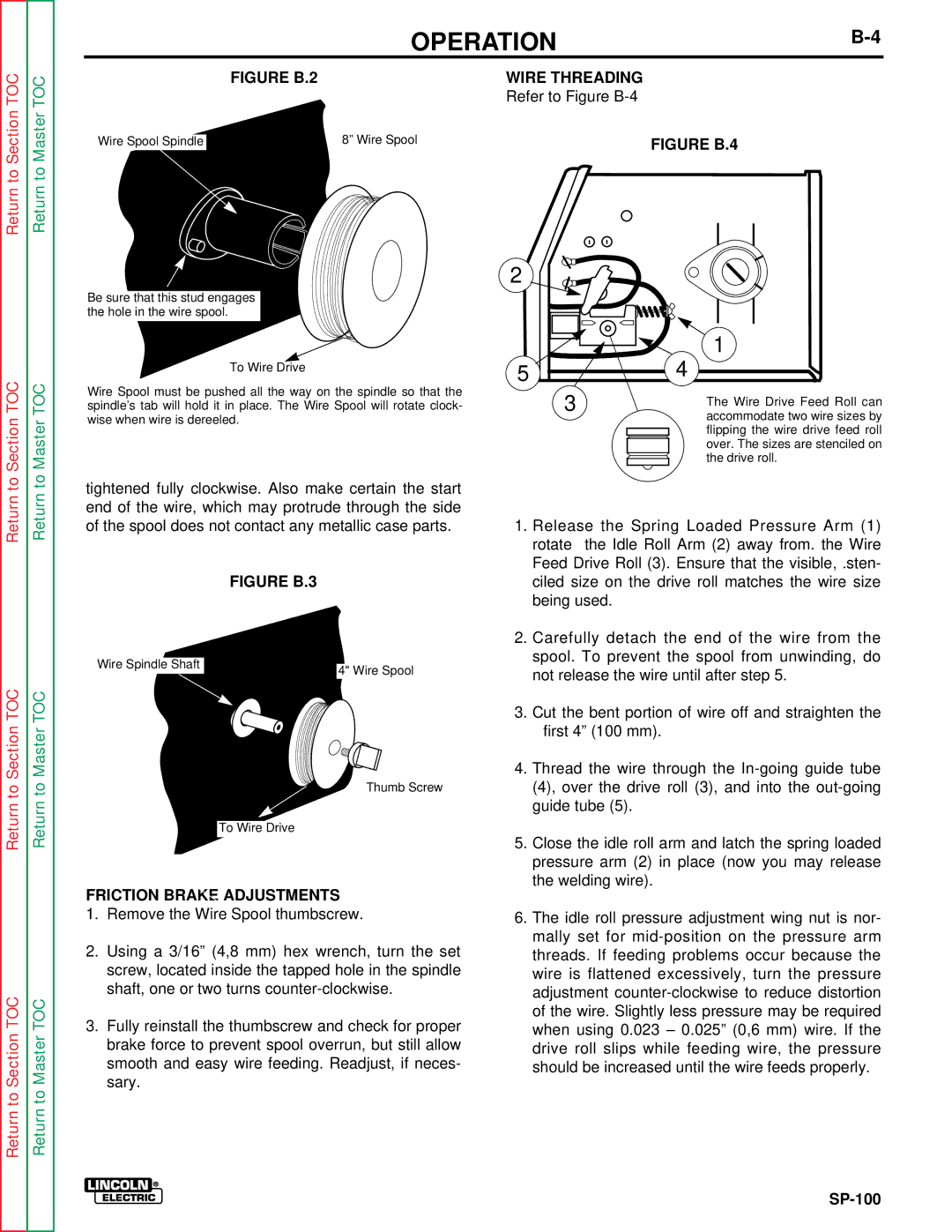

| FIGURE B.4 | ||||||

|

|

|

|

|

|

|

|

to Master TOC

Be sure that this stud engages the hole in the wire spool.

To Wire Drive

Wire Spool must be pushed all the way on the spindle so that the spindle’s tab will hold it in place. The Wire Spool will rotate clock- wise when wire is dereeled.

2

5![]()

3

1

4

The Wire Drive Feed Roll can accommodate two wire sizes by flipping the wire drive feed roll over. The sizes are stenciled on the drive roll.

Return to

Return to Section TOC

Return to Section TOC

tightened fully clockwise. Also make certain the start end of the wire, which may protrude through the side of the spool does not contact any metallic case parts.

FIGURE B.3

Wire Spindle Shaft | 4" Wire Spool |

|

Thumb Screw

To Wire Drive

FRICTION BRAKE ADJUSTMENTS

1.Remove the Wire Spool thumbscrew.

2.Using a 3/16” (4,8 mm) hex wrench, turn the set screw, located inside the tapped hole in the spindle shaft, one or two turns

3.Fully reinstall the thumbscrew and check for proper brake force to prevent spool overrun, but still allow smooth and easy wire feeding. Readjust, if neces- sary.

1.Release the Spring Loaded Pressure Arm (1) rotate the Idle Roll Arm (2) away from. the Wire Feed Drive Roll (3). Ensure that the visible, .sten- ciled size on the drive roll matches the wire size being used.

2.Carefully detach the end of the wire from the spool. To prevent the spool from unwinding, do not release the wire until after step 5.

3.Cut the bent portion of wire off and straighten the first 4” (100 mm).

4.Thread the wire through the

5.Close the idle roll arm and latch the spring loaded pressure arm (2) in place (now you may release the welding wire).

6.The idle roll pressure adjustment wing nut is nor- mally set for