TOC

TOC

|

| OPERATION |

| |

FIGURE B.7 | CHANGING MACHINE OVER TO FEED |

| ||

|

| OTHER WIRE SIZES |

| |

Return to Section

Return to Section TOC

Return to Master

Return to Master TOC

Gun Cable

![]() Arc

Arc

Work Piece

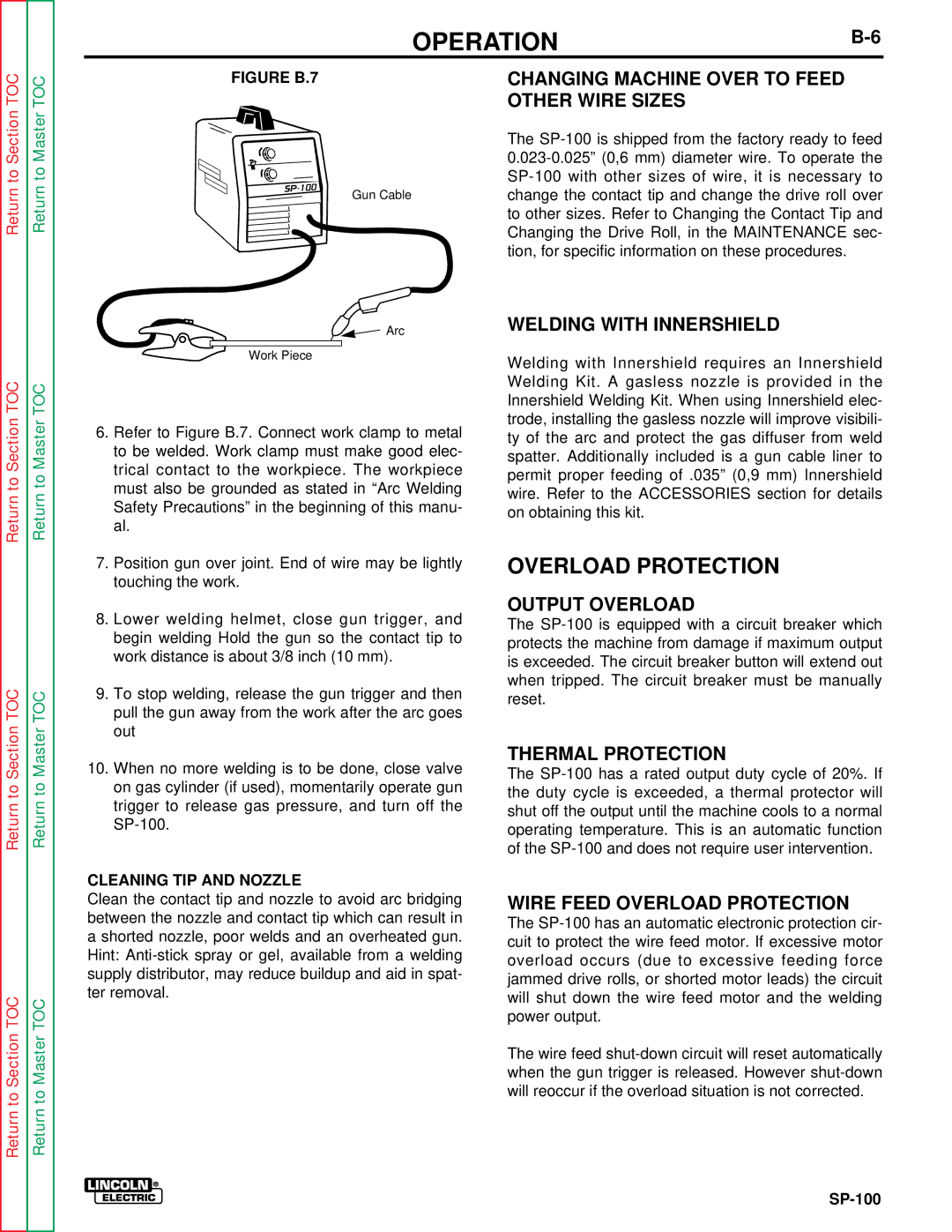

6.Refer to Figure B.7. Connect work clamp to metal to be welded. Work clamp must make good elec- trical contact to the workpiece. The workpiece must also be grounded as stated in “Arc Welding Safety Precautions” in the beginning of this manu- al.

7.Position gun over joint. End of wire may be lightly touching the work.

The

WELDING WITH INNERSHIELD

Welding with Innershield requires an Innershield Welding Kit. A gasless nozzle is provided in the Innershield Welding Kit. When using Innershield elec- trode, installing the gasless nozzle will improve visibili- ty of the arc and protect the gas diffuser from weld spatter. Additionally included is a gun cable liner to permit proper feeding of .035” (0,9 mm) Innershield wire. Refer to the ACCESSORIES section for details on obtaining this kit.

OVERLOAD PROTECTION

TOC

TOC

8.Lower welding helmet, close gun trigger, and begin welding Hold the gun so the contact tip to work distance is about 3/8 inch (10 mm).

9.To stop welding, release the gun trigger and then pull the gun away from the work after the arc goes out

OUTPUT OVERLOAD

The

Return to Section

Return to Section TOC

Return to Master

Return to Master TOC

10.When no more welding is to be done, close valve on gas cylinder (if used), momentarily operate gun trigger to release gas pressure, and turn off the

CLEANING TIP AND NOZZLE

Clean the contact tip and nozzle to avoid arc bridging between the nozzle and contact tip which can result in a shorted nozzle, poor welds and an overheated gun. Hint:

THERMAL PROTECTION

The

WIRE FEED OVERLOAD PROTECTION

The

The wire feed