.A complete Parts List is available at www.MillerWelds.com

.Welding wire birdnesting at the welding power source drive rolls may occur if this value is set too high.

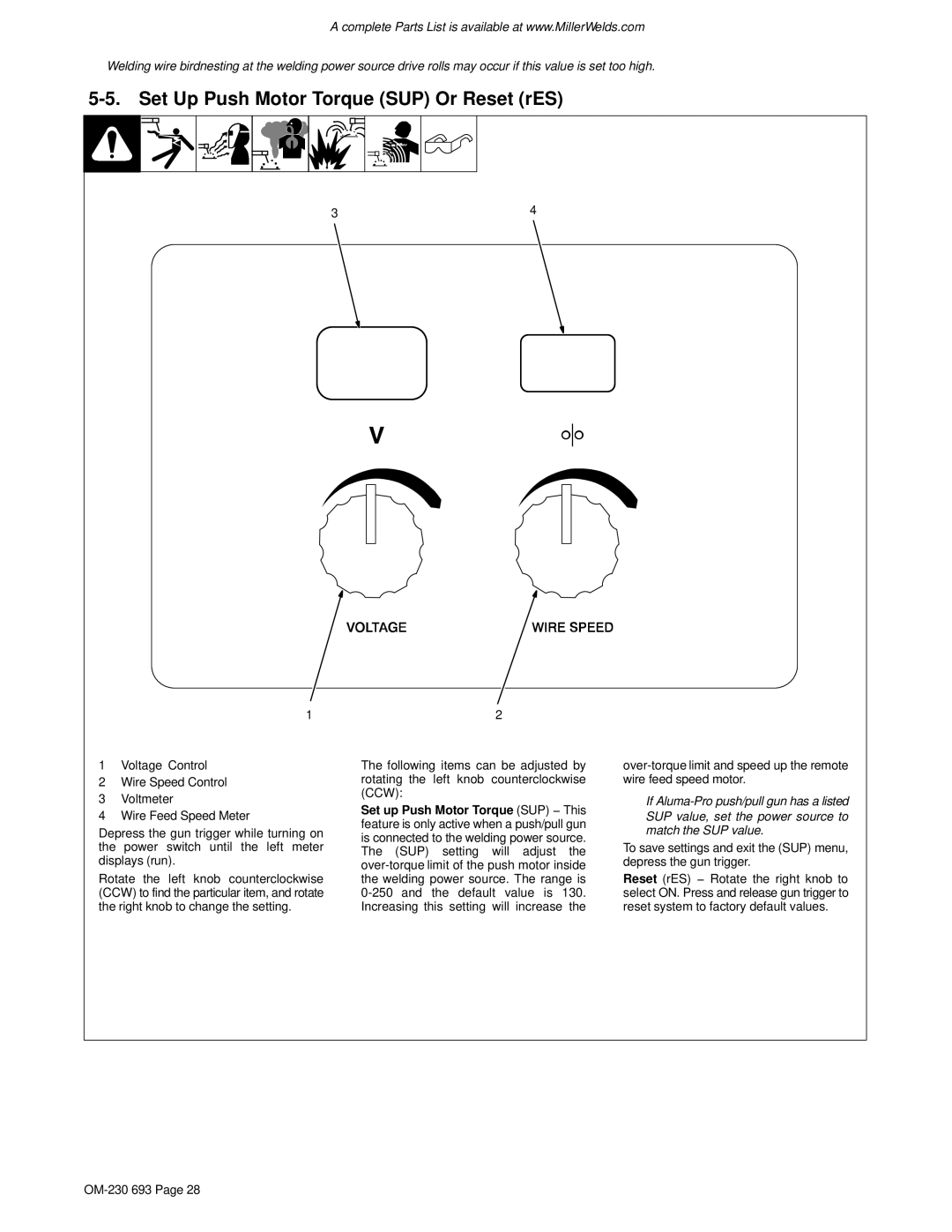

5-5. Set Up Push Motor Torque (SUP) Or Reset (rES)

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| 4 | |||||

3 | |||||||||||

1

1Voltage Control

2Wire Speed Control

3Voltmeter

4Wire Feed Speed Meter

Depress the gun trigger while turning on the power switch until the left meter displays (run).

Rotate the left knob counterclockwise (CCW) to find the particular item, and rotate the right knob to change the setting.

2

The following items can be adjusted by rotating the left knob counterclockwise (CCW):

Set up Push Motor Torque (SUP) − This feature is only active when a push/pull gun is connected to the welding power source. The (SUP) setting will adjust the

.If

To save settings and exit the (SUP) menu, depress the gun trigger.

Reset (rES) − Rotate the right knob to select ON. Press and release gun trigger to reset system to factory default values.