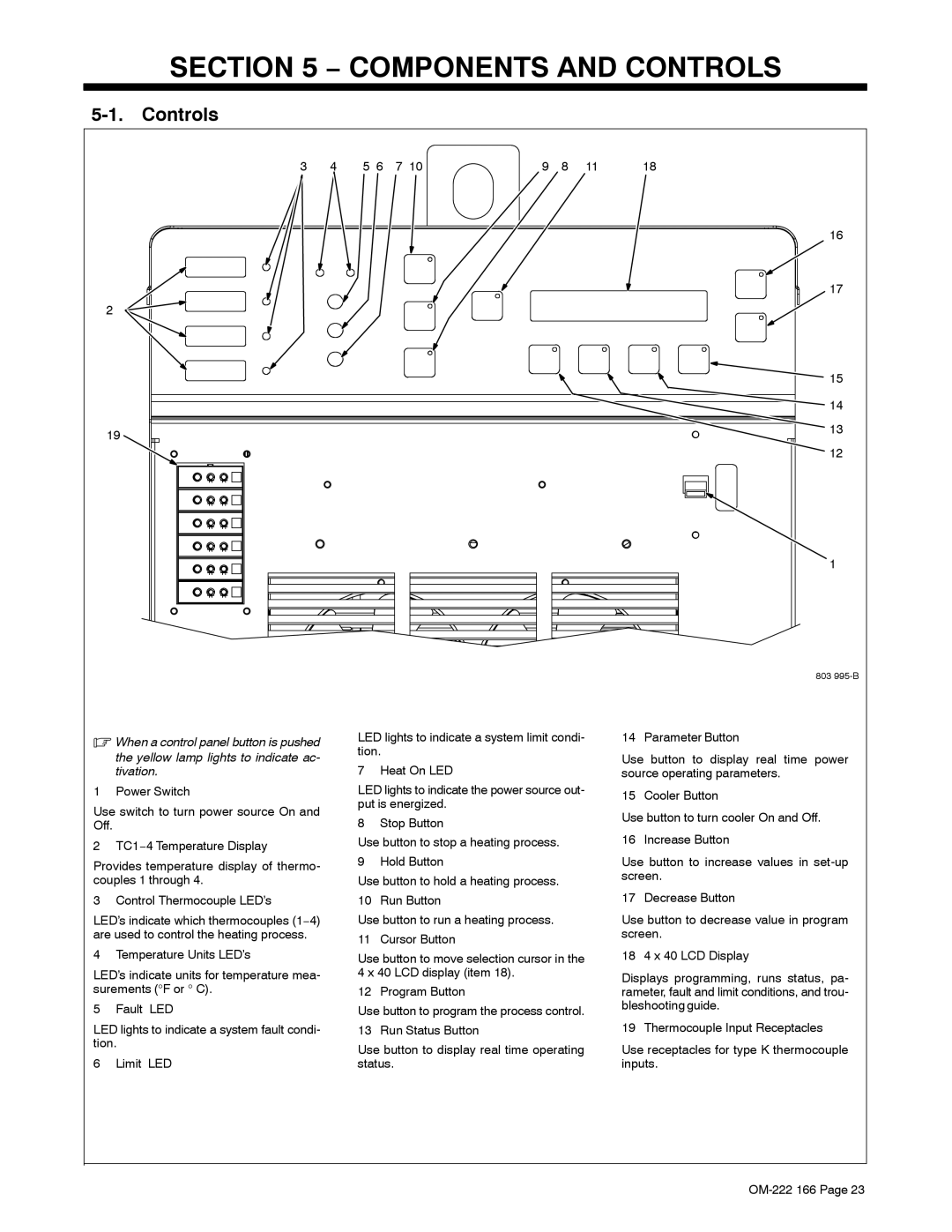

SECTION 5 − COMPONENTS AND CONTROLS

5-1. Controls

3 | 4 | 5 6 | 7 10 | 9 | 8 | 11 | 18 |

|

|

|

|

|

|

| 16 |

|

|

|

|

|

|

| 17 |

2 |

|

|

|

|

|

|

|

|

|

|

|

|

|

| 15 |

|

|

|

|

|

|

| 14 |

19 |

|

|

|

|

|

| 13 |

|

|

|

|

|

|

| |

|

|

|

|

|

|

| 12 |

1

803

.When a control panel button is pushed

the yellow lamp lights to indicate ac- tivation.

1 Power Switch

Use switch to turn power source On and Off.

2 TC1−4 Temperature Display

Provides temperature display of thermo- couples 1 through 4.

3 Control Thermocouple LED’s

LED’s indicate which thermocouples (1−4) are used to control the heating process.

4 Temperature Units LED’s

LED’s indicate units for temperature mea- surements (°F or ° C).

5 Fault LED

LED lights to indicate a system fault condi- tion.

6 Limit LED

LED lights to indicate a system limit condi- tion.

7 Heat On LED

LED lights to indicate the power source out- put is energized.

8 Stop Button

Use button to stop a heating process.

9 Hold Button

Use button to hold a heating process.

10 Run Button

Use button to run a heating process.

11 Cursor Button

Use button to move selection cursor in the 4 x 40 LCD display (item 18).

12 Program Button

Use button to program the process control. 13 Run Status Button

Use button to display real time operating status.

14 Parameter Button

Use button to display real time power source operating parameters.

15 Cooler Button

Use button to turn cooler On and Off.

16 Increase Button

Use button to increase values in

17 Decrease Button

Use button to decrease value in program screen.

18 4 x 40 LCD Display

Displays programming, runs status, pa- rameter, fault and limit conditions, and trou- bleshooting guide.

19 Thermocouple Input Receptacles

Use receptacles for type K thermocouple inputs.