9-7. Removing Wrapper and Measuring Input Capacitor Voltage

Tools Needed:

5/16, 3/8 in

! 900 Volts dc can be present on the capacitor bus and significant DC voltage can remain on capacitors after unit is Off. Always check the voltage on inverter assembly as shown to be sure the input capacitors have discharged before working on unit.

1

+ lead to right bus terminal, | 3 |

− lead to left bus terminal |

|

! Turn Off welding power source, and disconnect input power.

! Significant DC voltage can remain on capacitors after unit is Off. Always check the voltage as shown to be sure the input capacitors have discharged before working on unit.

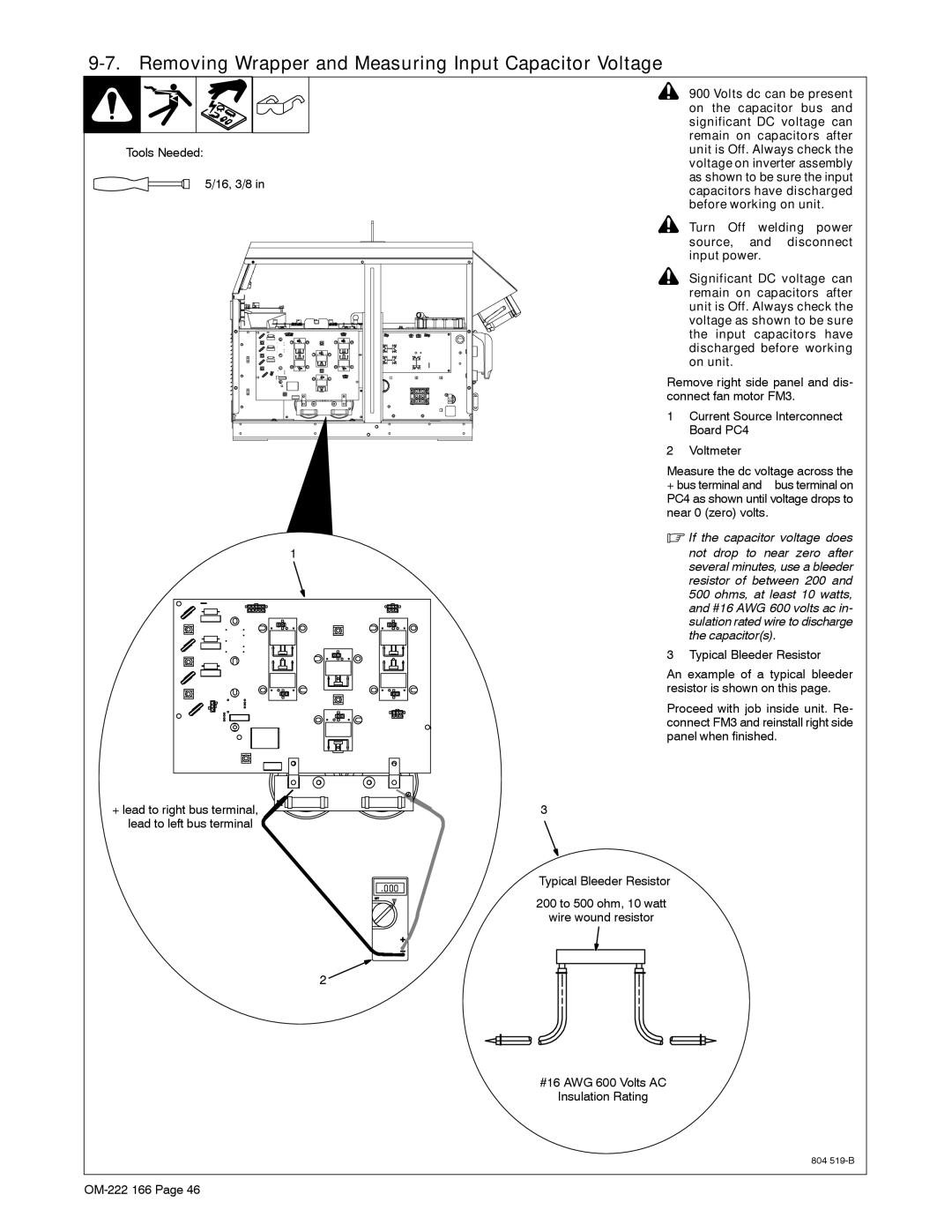

Remove right side panel and dis- connect fan motor FM3.

1Current Source Interconnect Board PC4

2Voltmeter

Measure the dc voltage across the

+bus terminal and − bus terminal on PC4 as shown until voltage drops to near 0 (zero) volts.

.If the capacitor voltage does

not drop to near zero after several minutes, use a bleeder resistor of between 200 and 500 ohms, at least 10 watts, and #16 AWG 600 volts ac in- sulation rated wire to discharge the capacitor(s).

3 Typical Bleeder Resistor

An example of a typical bleeder resistor is shown on this page.

Proceed with job inside unit. Re- connect FM3 and reinstall right side panel when finished.

Typical Bleeder Resistor

200 to 500 ohm, 10 watt

wire wound resistor

2 ![]()

#16 AWG 600 Volts AC

Insulation Rating

804