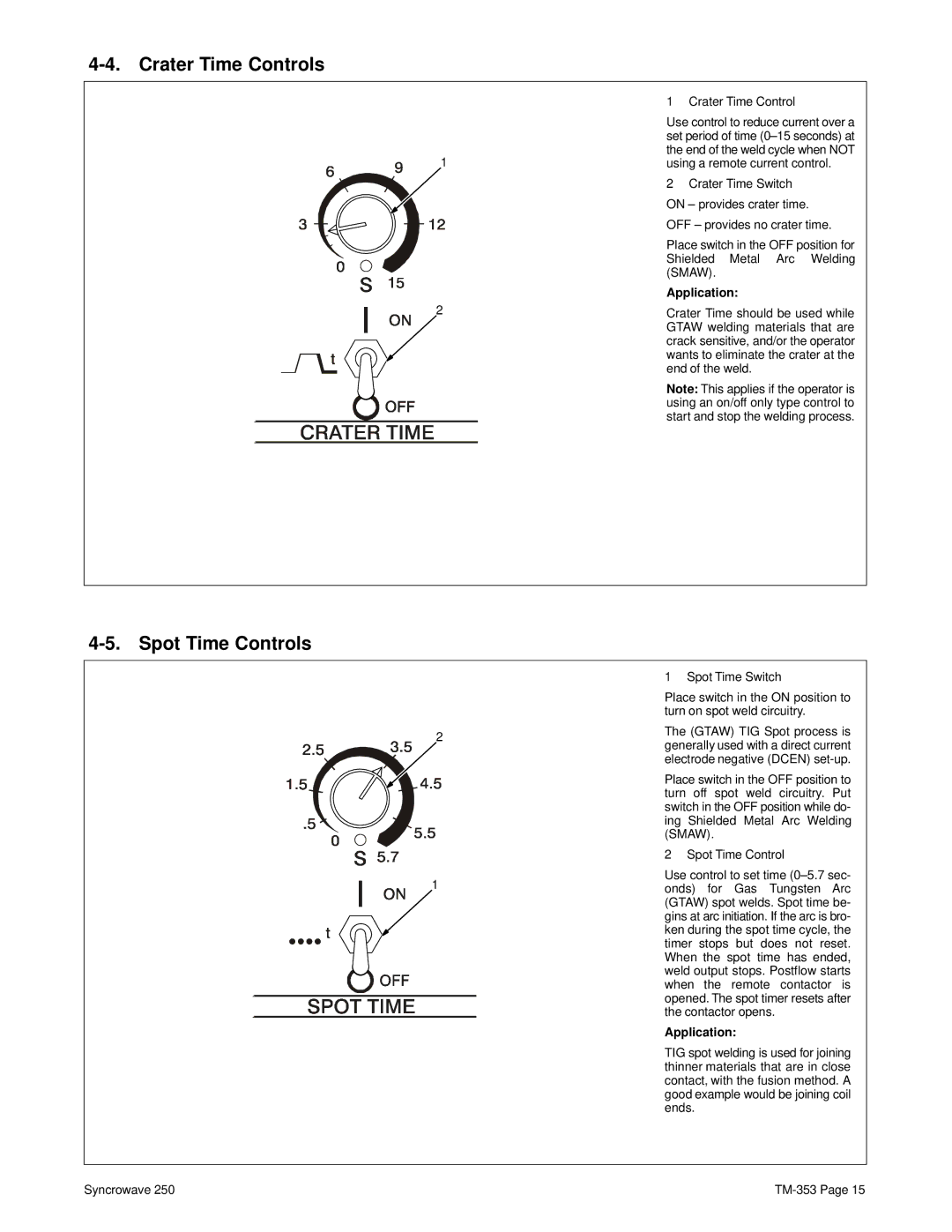

4-4. Crater Time Controls

1

2

1 Crater Time Control

Use control to reduce current over a set period of time

2 Crater Time Switch

ON – provides crater time.

OFF – provides no crater time.

Place switch in the OFF position for Shielded Metal Arc Welding (SMAW).

Application:

Crater Time should be used while GTAW welding materials that are crack sensitive, and/or the operator wants to eliminate the crater at the end of the weld.

Note: This applies if the operator is using an on/off only type control to start and stop the welding process.

4-5. Spot Time Controls

2

1

1 Spot Time Switch

Place switch in the ON position to turn on spot weld circuitry.

The (GTAW) TIG Spot process is generally used with a direct current electrode negative (DCEN)

Place switch in the OFF position to turn off spot weld circuitry. Put switch in the OFF position while do- ing Shielded Metal Arc Welding (SMAW).

2 Spot Time Control

Use control to set time

Application:

TIG spot welding is used for joining thinner materials that are in close contact, with the fusion method. A good example would be joining coil ends.

Syncrowave 250 |