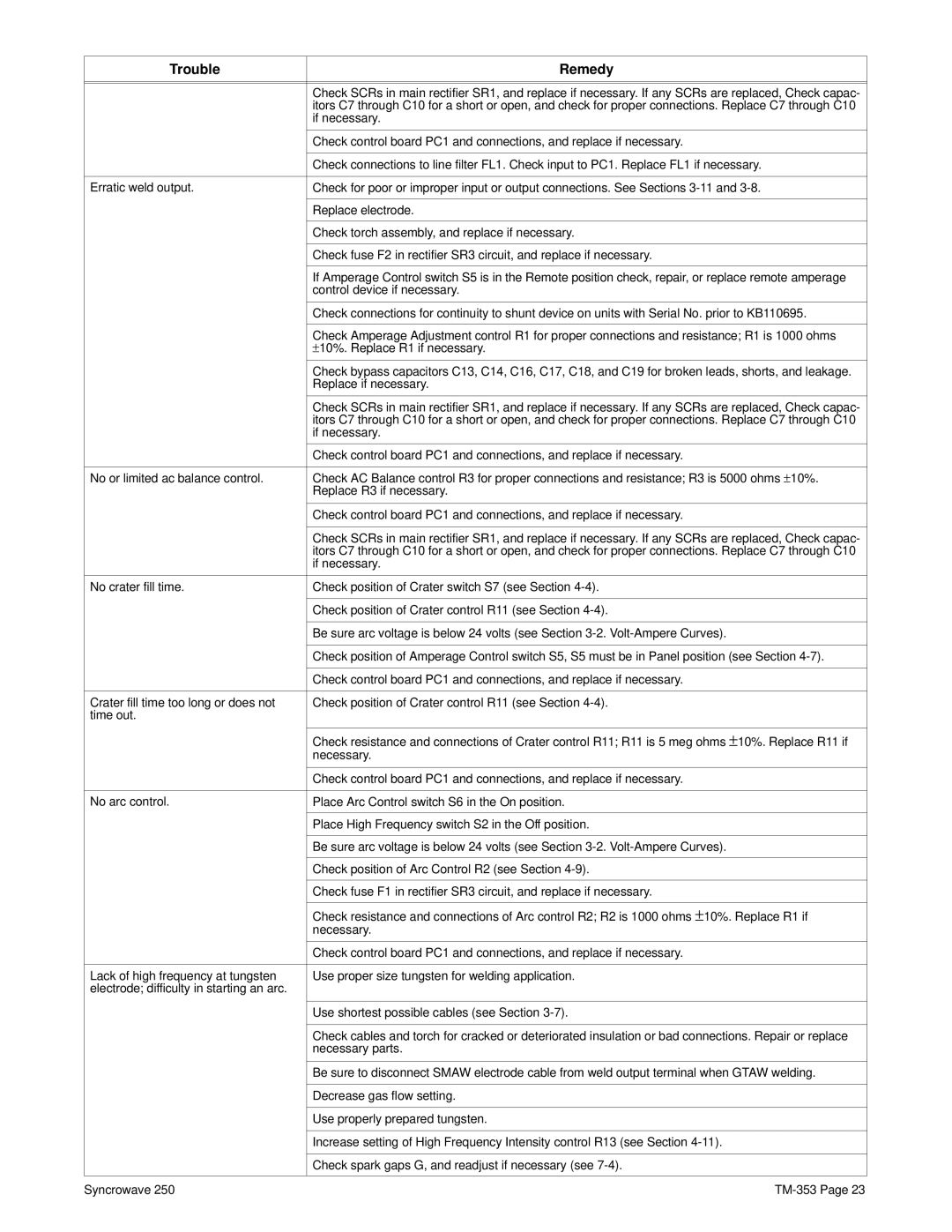

Trouble | Remedy |

|

|

|

|

| Check SCRs in main rectifier SR1, and replace if necessary. If any SCRs are replaced, Check capac- |

| itors C7 through C10 for a short or open, and check for proper connections. Replace C7 through C10 |

| if necessary. |

|

|

| Check control board PC1 and connections, and replace if necessary. |

|

|

| Check connections to line filter FL1. Check input to PC1. Replace FL1 if necessary. |

|

|

Erratic weld output. | Check for poor or improper input or output connections. See Sections |

|

|

| Replace electrode. |

|

|

| Check torch assembly, and replace if necessary. |

|

|

| Check fuse F2 in rectifier SR3 circuit, and replace if necessary. |

|

|

| If Amperage Control switch S5 is in the Remote position check, repair, or replace remote amperage |

| control device if necessary. |

|

|

| Check connections for continuity to shunt device on units with Serial No. prior to KB110695. |

|

|

| Check Amperage Adjustment control R1 for proper connections and resistance; R1 is 1000 ohms |

| ± 10%. Replace R1 if necessary. |

|

|

| Check bypass capacitors C13, C14, C16, C17, C18, and C19 for broken leads, shorts, and leakage. |

| Replace if necessary. |

|

|

| Check SCRs in main rectifier SR1, and replace if necessary. If any SCRs are replaced, Check capac- |

| itors C7 through C10 for a short or open, and check for proper connections. Replace C7 through C10 |

| if necessary. |

|

|

| Check control board PC1 and connections, and replace if necessary. |

|

|

No or limited ac balance control. | Check AC Balance control R3 for proper connections and resistance; R3 is 5000 ohms ± 10%. |

| Replace R3 if necessary. |

|

|

| Check control board PC1 and connections, and replace if necessary. |

|

|

| Check SCRs in main rectifier SR1, and replace if necessary. If any SCRs are replaced, Check capac- |

| itors C7 through C10 for a short or open, and check for proper connections. Replace C7 through C10 |

| if necessary. |

|

|

No crater fill time. | Check position of Crater switch S7 (see Section |

|

|

| Check position of Crater control R11 (see Section |

|

|

| Be sure arc voltage is below 24 volts (see Section |

|

|

| Check position of Amperage Control switch S5, S5 must be in Panel position (see Section |

|

|

| Check control board PC1 and connections, and replace if necessary. |

|

|

Crater fill time too long or does not | Check position of Crater control R11 (see Section |

time out. |

|

|

|

| Check resistance and connections of Crater control R11; R11 is 5 meg ohms ± 10%. Replace R11 if |

| necessary. |

|

|

| Check control board PC1 and connections, and replace if necessary. |

|

|

No arc control. | Place Arc Control switch S6 in the On position. |

|

|

| Place High Frequency switch S2 in the Off position. |

|

|

| Be sure arc voltage is below 24 volts (see Section |

|

|

| Check position of Arc Control R2 (see Section |

|

|

| Check fuse F1 in rectifier SR3 circuit, and replace if necessary. |

|

|

| Check resistance and connections of Arc control R2; R2 is 1000 ohms ± 10%. Replace R1 if |

| necessary. |

|

|

| Check control board PC1 and connections, and replace if necessary. |

|

|

Lack of high frequency at tungsten | Use proper size tungsten for welding application. |

electrode; difficulty in starting an arc. |

|

|

|

| Use shortest possible cables (see Section |

|

|

| Check cables and torch for cracked or deteriorated insulation or bad connections. Repair or replace |

| necessary parts. |

|

|

| Be sure to disconnect SMAW electrode cable from weld output terminal when GTAW welding. |

|

|

| Decrease gas flow setting. |

|

|

| Use properly prepared tungsten. |

|

|

| Increase setting of High Frequency Intensity control R13 (see Section |

|

|

| Check spark gaps G, and readjust if necessary (see |

|

|

Syncrowave 250 |