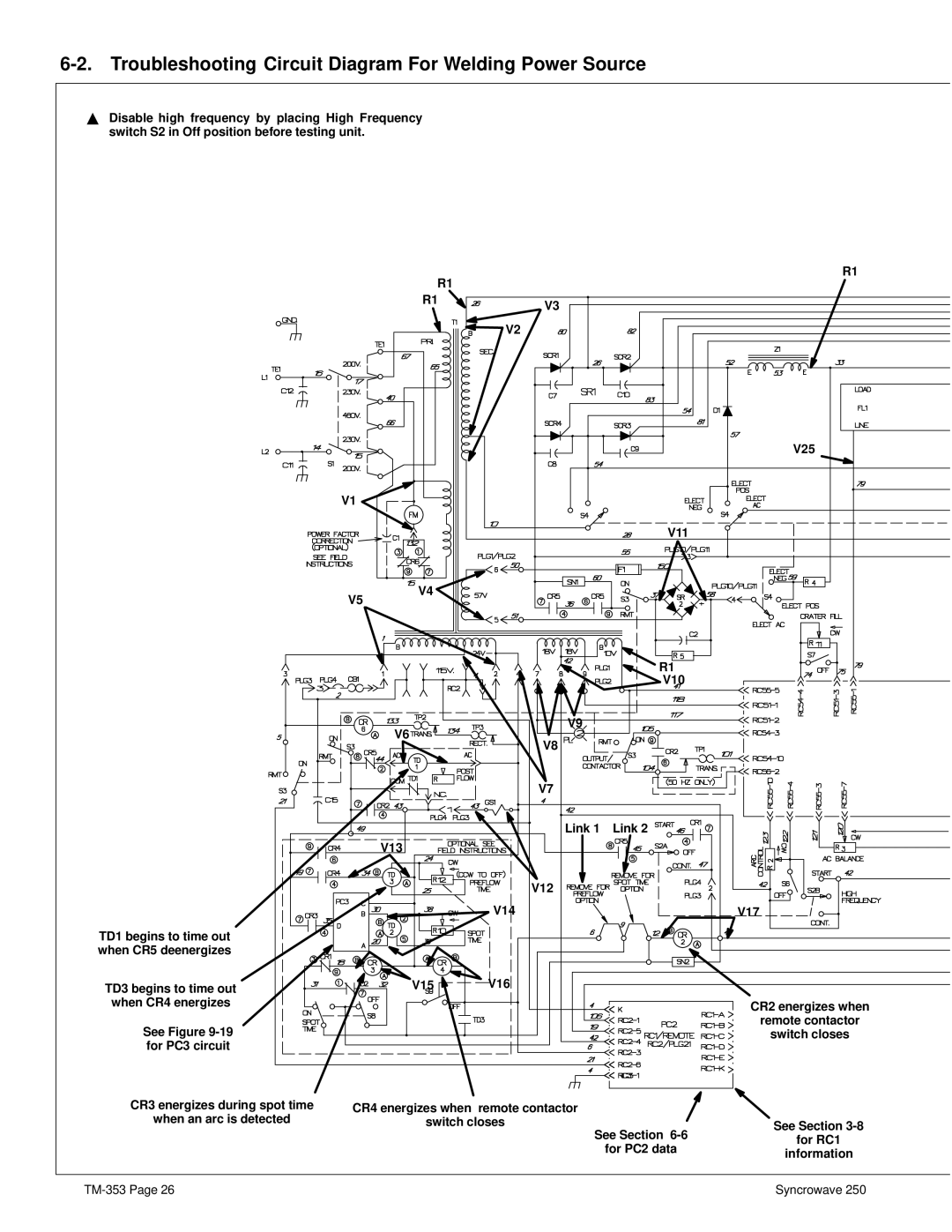

6-2. Troubleshooting Circuit Diagram For Welding Power Source

YDisable high frequency by placing High Frequency switch S2 in Off position before testing unit.

R1

R1

R1 | V3 |

| |

| V2 |

|

|

| V25 |

| V1 |

|

|

|

|

| V11 |

| V4 |

|

|

| V5 |

|

|

|

|

| R1 |

|

|

| V10 |

| V6 | V9 |

|

| V8 |

| |

|

|

| |

|

| V7 |

|

|

| Link 1 | Link 2 |

| V13 |

|

|

|

| V12 |

|

|

| V14 | V17 |

TD1 begins to time out |

|

|

|

when CR5 deenergizes |

|

|

|

TD3 begins to time out | V15 | V16 |

|

when CR4 energizes |

|

| CR2 energizes when |

|

|

| |

See Figure |

|

| remote contactor |

|

| switch closes | |

for PC3 circuit |

|

|

|

CR3 energizes during spot time | CR4 energizes when remote contactor |

| |

when an arc is detected | switch closes | See Section | |

See Section | for RC1 | |

for PC2 data | ||

information | ||

|

Syncrowave 250 |