inspection

3.Insert and remove the dipstick without screwing it into the filler neck. Check the oil level shown on the dipstick.

4.If the oil level is low (Figure 16), fill to the edge of the oil filler hole with the recommended oil type as listed in Table 4. Reference Table 3 for maximum engine oil capacity.

Figure 16. Engine Oil Dipstick (Oil Level)

Table 4. Oil Type

Season | Temperature | Oil Type |

Summer | 25°C or Higher | SAE |

Spring/Fall | 25°C~10°C | SAE |

Winter | 0°C or Lower | SAE |

![]() DANGER

DANGER

EXPLOSIVE FUEL!

Motor fuels are highly flammable and can be dangerous if mishandled. DO NOT smoke while refueling. DO NOT attempt to refuel the trowel if the engine is hot! or running.

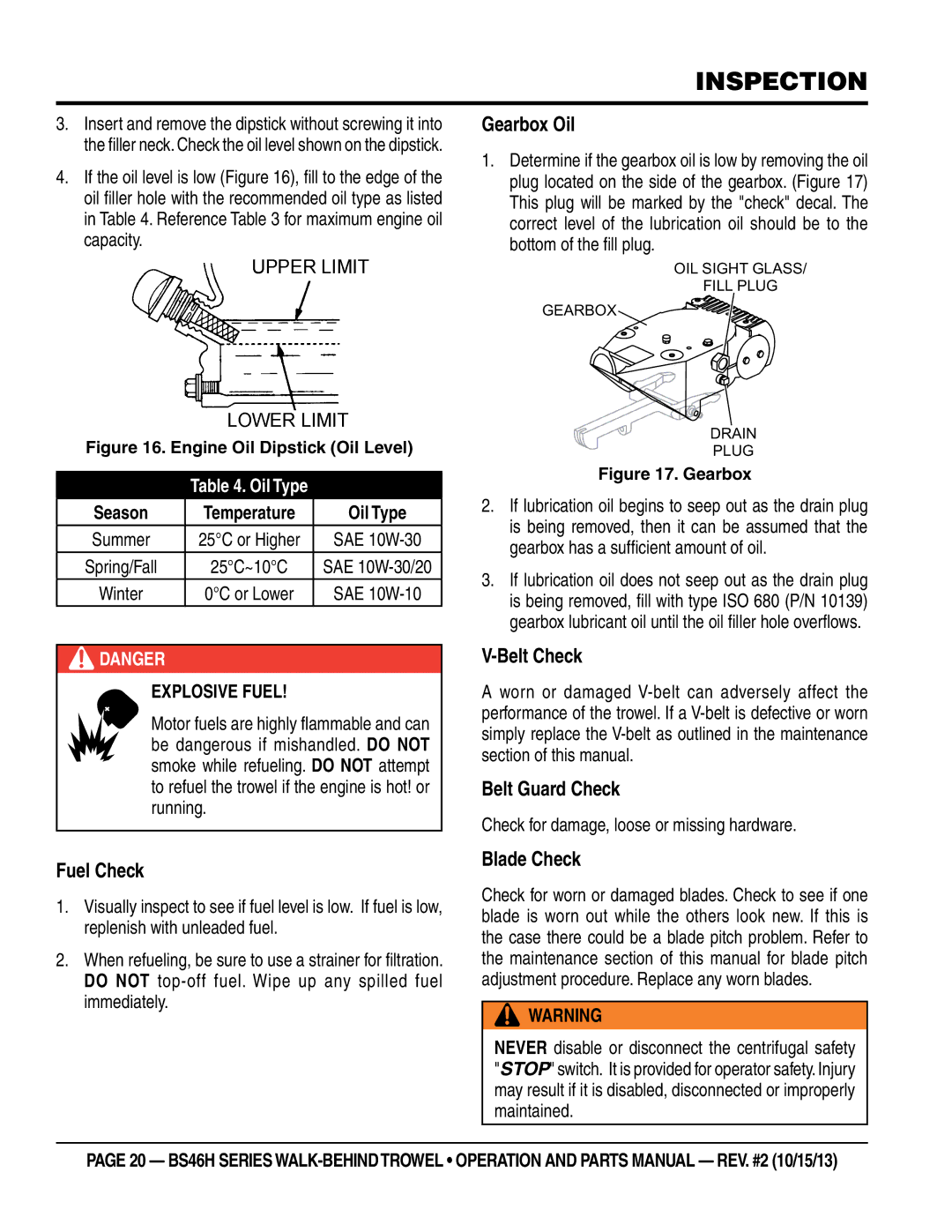

Gearbox Oil

1.Determine if the gearbox oil is low by removing the oil plug located on the side of the gearbox. (Figure 17) This plug will be marked by the "check" decal. The correct level of the lubrication oil should be to the bottom of the fill plug.

OIL SIGHT GLASS/

FILL PLUG

GEARBOX

DRAIN

PLUG

Figure 17. Gearbox

2.If lubrication oil begins to seep out as the drain plug is being removed, then it can be assumed that the gearbox has a sufficient amount of oil.

3.If lubrication oil does not seep out as the drain plug is being removed, fill with type ISO 680 (P/N 10139) gearbox lubricant oil until the oil filler hole overflows.

V-Belt Check

A worn or damaged

Belt Guard Check

Check for damage, loose or missing hardware.

Fuel Check

1.Visually inspect to see if fuel level is low. If fuel is low, replenish with unleaded fuel.

2.When refueling, be sure to use a strainer for filtration. DO NOT

Blade Check

Check for worn or damaged blades. Check to see if one blade is worn out while the others look new. If this is the case there could be a blade pitch problem. Refer to the maintenance section of this manual for blade pitch adjustment procedure. Replace any worn blades.

![]() WARNING

WARNING

NEVER disable or disconnect the centrifugal safety "STOP" switch. It is provided for operator safety. Injury may result if it is disabled, disconnected or improperly maintained.

page 20 — BS46H SERIES