maintenance

2.Pitch the blades as flat as possible. The pitch adjustment bolts (Figure 49) should all barely make contact (0.10 inch max. clearance) with the lower wear plate on the spider. All pitch alignment bolts should be spaced the same distance from the lower wear plate. If one is not making contact, adjustment will be necessary.

GEARBOX

TROWEL

ARM

STEEL TEST | MOUNTING | |

BAR | ||

SURFACE | ||

|

BLADE |

PITCHLOWER

ADJUSTMENT WEAR PLATE

BOLT

Figure 49. Correct Blade Pitch (Flat)

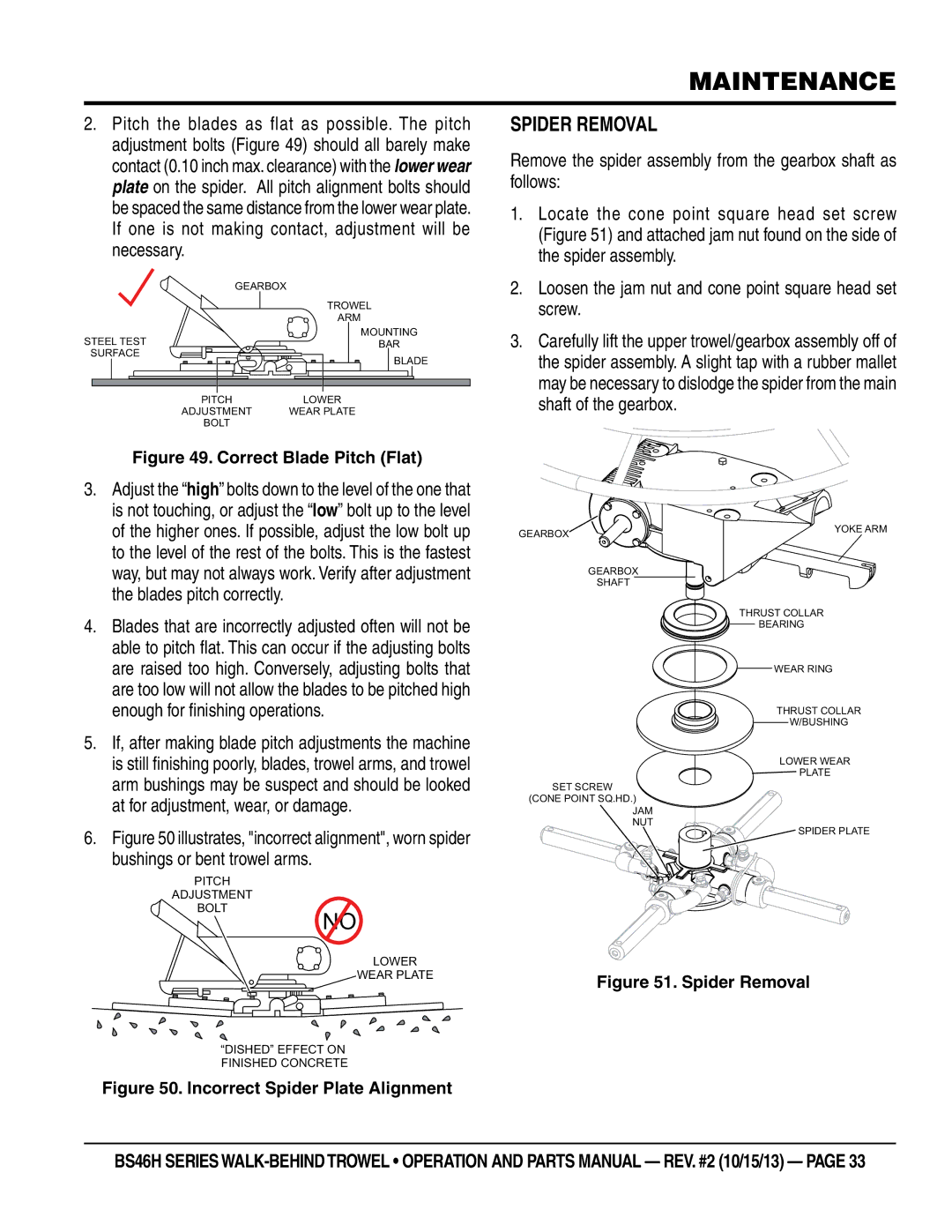

Spider removal

Remove the spider assembly from the gearbox shaft as follows:

1.Locate the cone point square head set screw (Figure 51) and attached jam nut found on the side of the spider assembly.

2.Loosen the jam nut and cone point square head set screw.

3.Carefully lift the upper trowel/gearbox assembly off of the spider assembly. A slight tap with a rubber mallet may be necessary to dislodge the spider from the main shaft of the gearbox.

3.Adjust the “high” bolts down to the level of the one that is not touching, or adjust the “low” bolt up to the level of the higher ones. If possible, adjust the low bolt up to the level of the rest of the bolts. This is the fastest way, but may not always work. Verify after adjustment the blades pitch correctly.

4.Blades that are incorrectly adjusted often will not be able to pitch flat. This can occur if the adjusting bolts are raised too high. Conversely, adjusting bolts that are too low will not allow the blades to be pitched high enough for finishing operations.

5.If, after making blade pitch adjustments the machine is still finishing poorly, blades, trowel arms, and trowel arm bushings may be suspect and should be looked at for adjustment, wear, or damage.

6.Figure 50 illustrates, "incorrect alignment", worn spider

bushings or bent trowel arms.

PITCH

ADJUSTMENT

BOLT

NO

LOWER

GEARBOX

GEARBOX

SHAFT

SET SCREW

(CONE POINT SQ.HD.)

JAM

NUT

YOKE ARM

THRUST COLLAR

BEARING

WEAR RING

THRUST COLLAR

W/BUSHING

LOWER WEAR

PLATE

SPIDER PLATE

WEAR PLATE

“DISHED” EFFECT ON FINISHED CONCRETE