Model BS46HLE

Fuel and chemical exposure Warnings

Silicosis Warning

Silicosis/Respiratory Warnings

WALK-BEHIND Trowel

Table of Contents

Completely

Training checklist

Daily pre-Operation checklist

Daily pre-operation checklist

SaFeTy meSSageS

Safety Information

GENEraL SafETy

Before servicing equipment

TrOwEL SafETy

ENgiNE SafETy

Order Form PT-160

TraNSpOrTiNg SafETy

FUeL SaFeTy

Label must remain with the engine for its entire life

ENvIRONmeNTaL SaFeTy/DeCOmmISSIONINg

EmISSIONS INFORmaTION

Emission control Label

Side View

Trowel SPECIFICATIONS/DIMENSIONS

11997+A12010 in m/s2 ΣA8

Engine Specifications

General information

15 14 13 12

Trowel Components

Initial Servicing

Engine Components

Vibratory T-Handle Bar Placement

Assembly and installation

Assembly and Installation

Handle Tube Installation

Ground point

Safety Stop Switch Connection

Pitch Cable Installation

Shown in Figure

Engine Oil Check

Inspection

Before Starting

Fuel Check

Gearbox Oil

Belt Check

Belt Guard Check

Lifting Bale

Inspection/operation

Operation

Lifting the Trowel Onto a Slab

Place the choke lever in the Open position

Operation

Starting the Engine

Place the engine fuel valve lever in the on position

Starter Grip

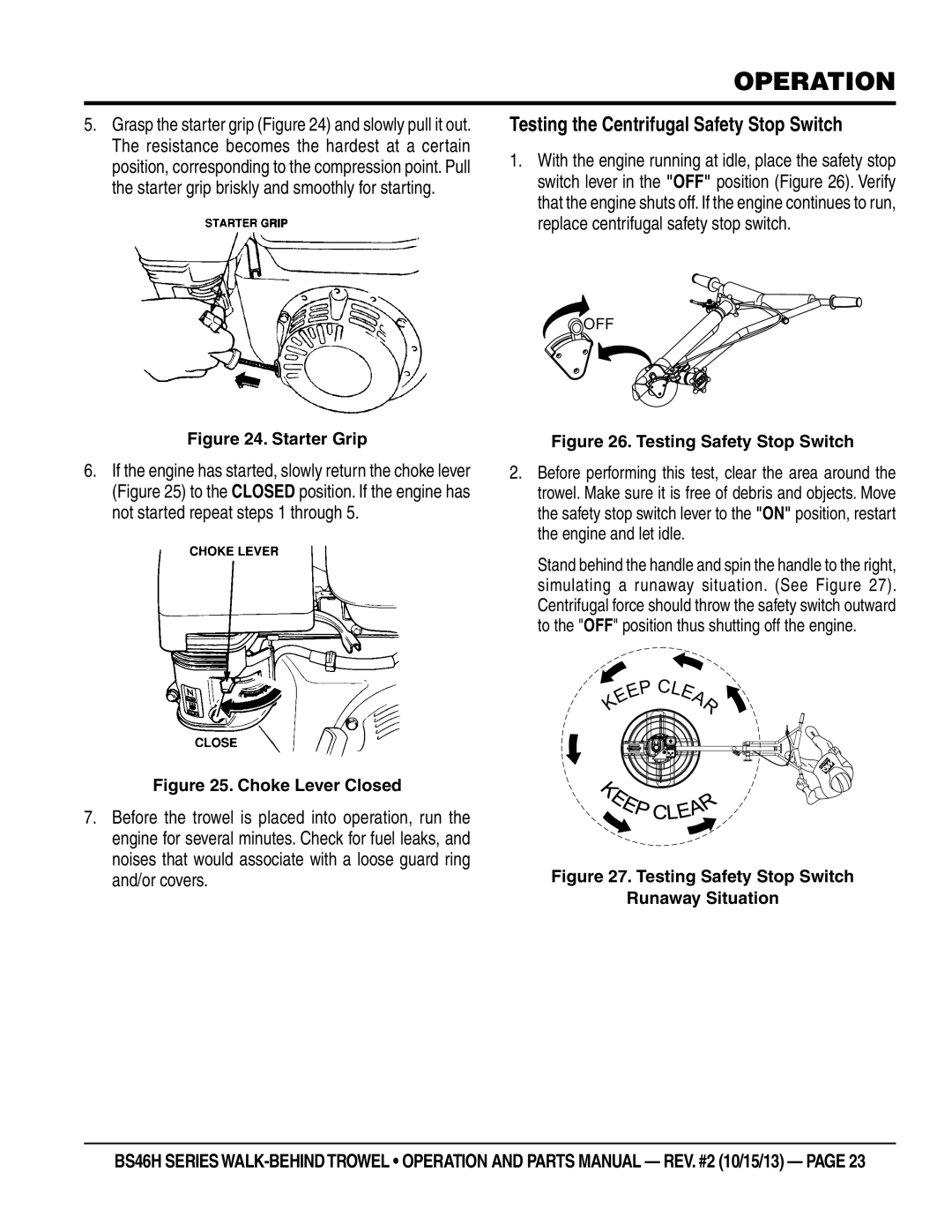

Testing the Centrifugal Safety Stop Switch

Pitching the Blades Quick Pitch Handle

To Begin Troweling

Concrete Finishing Techniques

Pitching the Blades Standard Handle

Maneuvering the Trowel

Maneuvering the Trowel

Stopping The Engine

Place the safety stop switch in the OFF position

Float Discs Optional

Options

Combo Blades

Clip-On Float Blades Optional

Quick Pitch Handle Optional

Trowel Arm Adjustment Tool Optional

Maintenance

Engine check

General Cleanliness

Engine Air Cleaner

Never use a spark plug of incorrect heat range

Engine oil

Spark Plug

Belt

Blade Pitch Adjustment Procedure

Spark arrester cleaning

Bushings or bent trowel arms

Spider removal

Remove the trowel arm from the spider plate

Changing blades

Trowel arm removal

Shaft and the test surface

Trowel arm Lever adjustment

Checking trowel arm straightness

Ensure the fixture arm is in the up position

Installing Pans Onto Finisher Blades

ReAssembly

LONG-TERM Storage

Troubleshooting engine

Troubleshooting

Air cleaner dirty? Clean or replace air cleaner

Or malfunctioning? Or replace switch if necessary

Troubleshooting Walk-Behind Trowel

Wiring Diagram

Page

Explanation of Code in Remarks Column

To 3 Units

Suggested Spare Parts

Nameplate and Decals

DECAL, Serial PLATE, WBT-CHINA

ISO DECAL, Read MANUAL, 2.00 DIA

ISO DECAL, LIFTING/CRUSH, 2.4 X

ISO DECAL, ASK for TRAINING, 2.00 DIA

Standard Handle Assy

WASHER, FENDER, 1.5OD X 3/8ID

Wire ASSY., Kill Switch

Switch ASSY., Kill

SPACER, Slide Block Guide

Quick-pitch Handle ASSY. option

Spring Center Balance

NUT , QP Trim Cntl Adjustment

Adjustment PIN

QP Adjustment Block

Guard Assy

SCREW, Fast Lead

Access PANEL, B Finisher

Guard Ring

CLIP, Fast Lead

Requires 26 OZ .8 Liters Gearbox Lubricant for Operation

Gearbox Assy

GEAR, Worm B Input Shaft

SEAL, OIL

FLANGE, Input Shaft

BEARING, CUP, Timken #M11910

Engine and clutch Assy

WEIGHT, Automatic Clutch

CONNECTOR, Splice TAP

WIRE, Safety Switch

Lifting Bale Assembly B FIN

14 1

Spider Assy

Spider Plate

Blade Assembly

Lock Washer 3/8 MED

BUSHING, Trowel ARM

Stabilizer Ring Assy

RING, STABILIZER, 16-1/2 ARM

0300B

1237

Blade Assy

Guard Ring LUG Ring

21906

See Notice below

0201

Engine service parts

17210ZE2822

17620Z4H020

28462ZE2W11

28462ZE3W01

Page

Page

HERE’S HOW to GET Help

![]() OFF

OFF