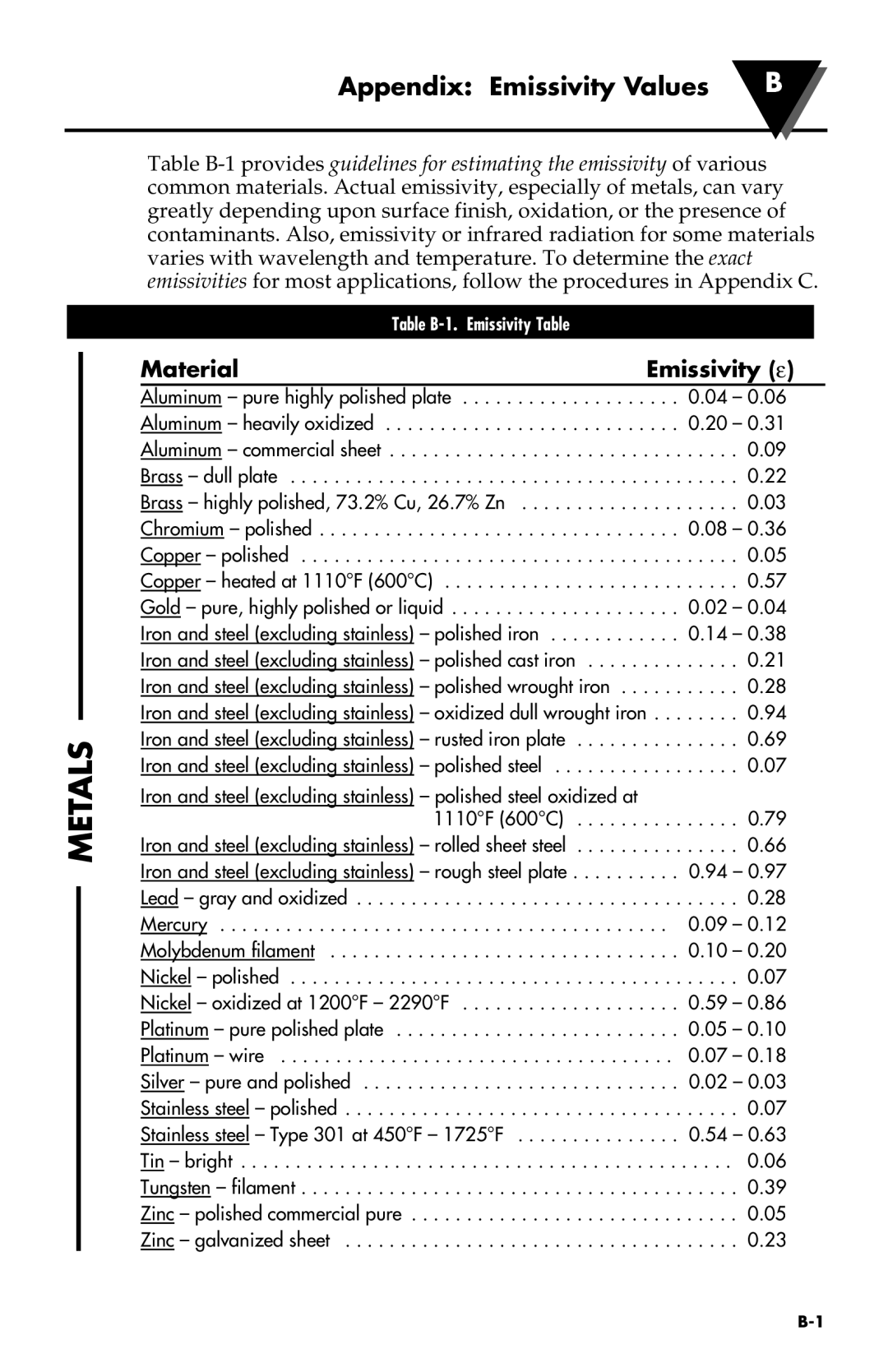

Appendix: Emissivity Values | B |

METALS

Table

| Table |

Material | Emissivity (ε) |

Aluminum – pure highly polished plate . . . . . . . . . . . . . . . . . . . . 0.04 – 0.06 Aluminum – heavily oxidized . . . . . . . . . . . . . . . . . . . . . . . . . . . 0.20 – 0.31 Aluminum – commercial sheet . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 0.09 Brass – dull plate . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 0.22 Brass – highly polished, 73.2% Cu, 26.7% Zn . . . . . . . . . . . . . . . . . . . . 0.03 Chromium – polished . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 0.08 – 0.36 Copper – polished . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 0.05 Copper – heated at 1110°F (600°C) . . . . . . . . . . . . . . . . . . . . . . . . . . . 0.57 Gold – pure, highly polished or liquid . . . . . . . . . . . . . . . . . . . . . 0.02 – 0.04 Iron and steel (excluding stainless) – polished iron . . . . . . . . . . . . 0.14 – 0.38 Iron and steel (excluding stainless) – polished cast iron . . . . . . . . . . . . . . 0.21 Iron and steel (excluding stainless) – polished wrought iron . . . . . . . . . . . 0.28 Iron and steel (excluding stainless) – oxidized dull wrought iron . . . . . . . . 0.94 Iron and steel (excluding stainless) – rusted iron plate . . . . . . . . . . . . . . . 0.69 Iron and steel (excluding stainless) – polished steel . . . . . . . . . . . . . . . . . 0.07

Iron and steel (excluding stainless) – polished steel oxidized at |

|

1110°F (600°C) | . . . . . 0.79 |

Iron and steel (excluding stainless) – rolled sheet steel | . . . . . 0.66 |

Iron and steel (excluding stainless) – rough steel plate | 0.94 – 0.97 |

Lead – gray and oxidized | . . . . . 0.28 |

Mercury | 0.09 – 0.12 |

Molybdenum filament | 0.10 – 0.20 |

Nickel – polished | . . . . . 0.07 |

Nickel – oxidized at 1200°F – 2290°F | 0.59 – 0.86 |

Platinum – pure polished plate | 0.05 – 0.10 |

Platinum – wire | 0.07 – 0.18 |

Silver – pure and polished | 0.02 – 0.03 |

Stainless steel – polished | . . . . . 0.07 |

Stainless steel – Type 301 at 450°F – 1725°F | 0.54 – 0.63 |

Tin – bright | . . . . . 0.06 |

Tungsten – filament | . . . . . 0.39 |

Zinc – polished commercial pure | . . . . . 0.05 |

Zinc – galvanized sheet | . . . . . 0.23 |