60149517, 60149518 specifications

The Pitco Frialator 60149518 and 60149517 are two highly regarded models in the realm of commercial fryers, tailored to meet the rigorous demands of busy kitchens. Renowned for their reliability and advanced features, these fryers exemplify engineering excellence and culinary efficiency.One of the standout characteristics of the Pitco Frialator models is their innovative design, which prioritizes efficient oil usage while enhancing the quality of fried foods. Both units are equipped with a patented “Oil Management System” that significantly extends oil life by reducing the rate of oxidation. This technology not only saves on oil costs but also ensures that food retains its flavor profile and quality, creating a better dining experience.

The fryers feature high-efficiency burners that provide quick heat-up times, ensuring that kitchen staff can deliver orders promptly. The 60149518 and 60149517 models are designed with adjustable temperature settings, allowing chefs to fine-tune cooking temperatures for different types of food. This versatility means that whether frying delicate seafood or hearty chicken, the equipment can accommodate various cooking requirements with ease.

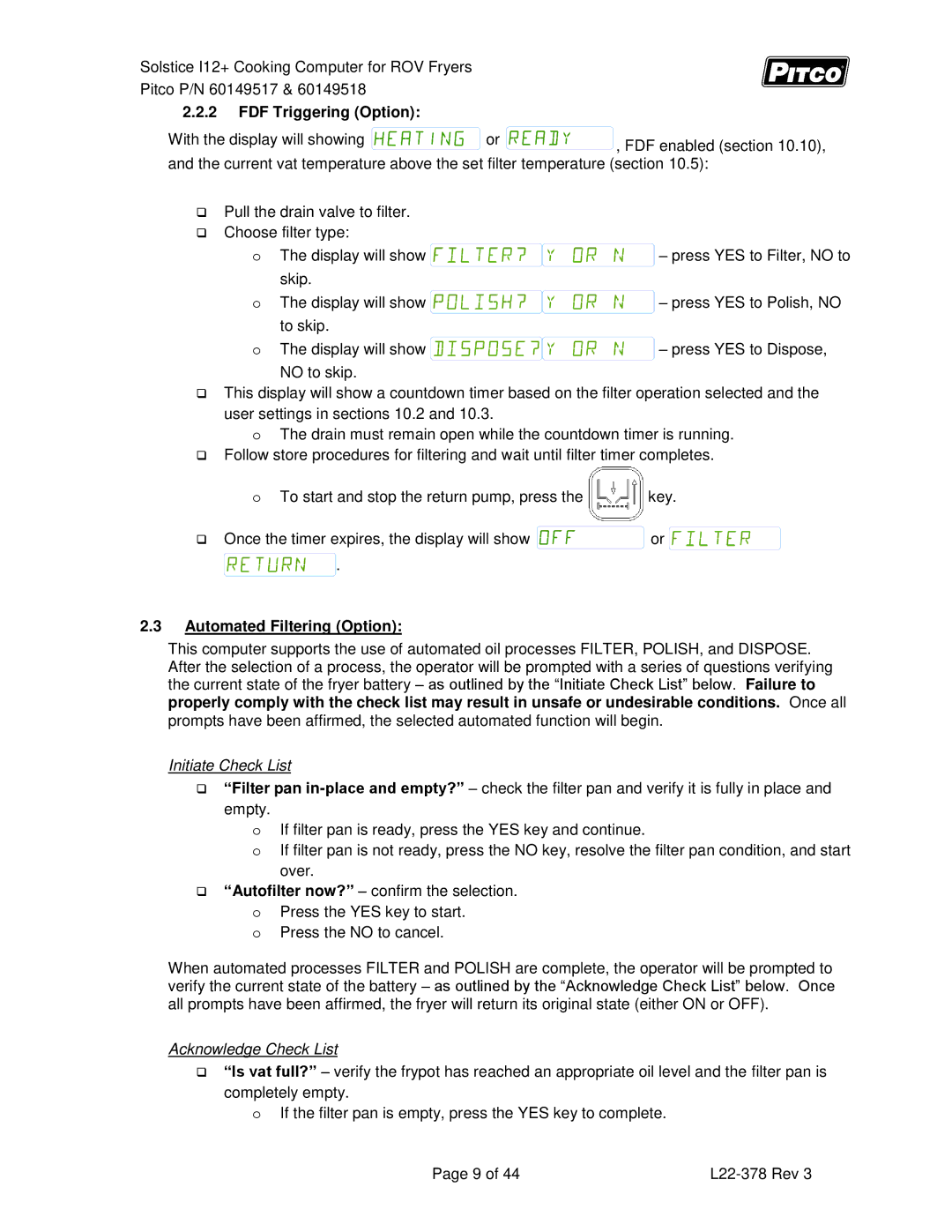

User-friendliness is another hallmark of the Pitco Frialator line. Both models boast simple controls and an intuitive interface, enabling team members to operate the fryers without extensive training. Safety is also a priority; with features like a built-in temperature safety cut-off switch, the fryers help to prevent overheating, minimizing the risk of accidents in a bustling kitchen environment.

Moreover, the construction quality of the Pitco Frialator fryers stands out. Made with durable stainless steel, they are built to withstand the rigors of daily use, providing longevity and reliability for commercial applications. The fryers also include significant drainage and filtration systems that allow for easy oil changes and maintenance, streamlining kitchen operations.

In conclusion, the Pitco Frialator 60149518 and 60149517 are exemplary models that combine advanced technology, user convenience, and robust construction. With their energy-efficient features and commitment to food quality, these fryers remain a top choice for restaurants and foodservice operations looking to maximize efficiency and deliver outstanding fried foods.