ALTERNATE ROUTER BITS

You are not limited to using the router bits supplied with your jig. Other router bits can be used to produce a different look or to work with thicker woods. Using alternate bits can help you produce more advanced joints (inlayed dovetails, etc.). Since 1/2" shank bits are stronger and are much less prone to deflection than the 1/4" shank bits, we recommend that you use the 1/2" shank bits with the 4210 and 4212 dovetail jigs, and with the 4211 and 4213 accessory kits.

THROUGH-DOVETAIL BITS

If you choose to purchase alternate

1.The dovetail bit must have a 7° angle. This angle matches the tapered fingers used to guide the straight bit.

2.The sum of the diameters of the dovetail and straight bits must equal 15/16". For example, a 5/8" dovetail bit must have a 5/16" straight bit - the sum of both equalling 15/16".

3.The length of the cutter determines the maximum thickness of wood that can be cut. The length of the cutter on the dovetail bit is the maximum thickness of the pin board. The length of the cutter on the straight bit is the maximum thickness of the tail board. If your bits have 1" cutters, you can make

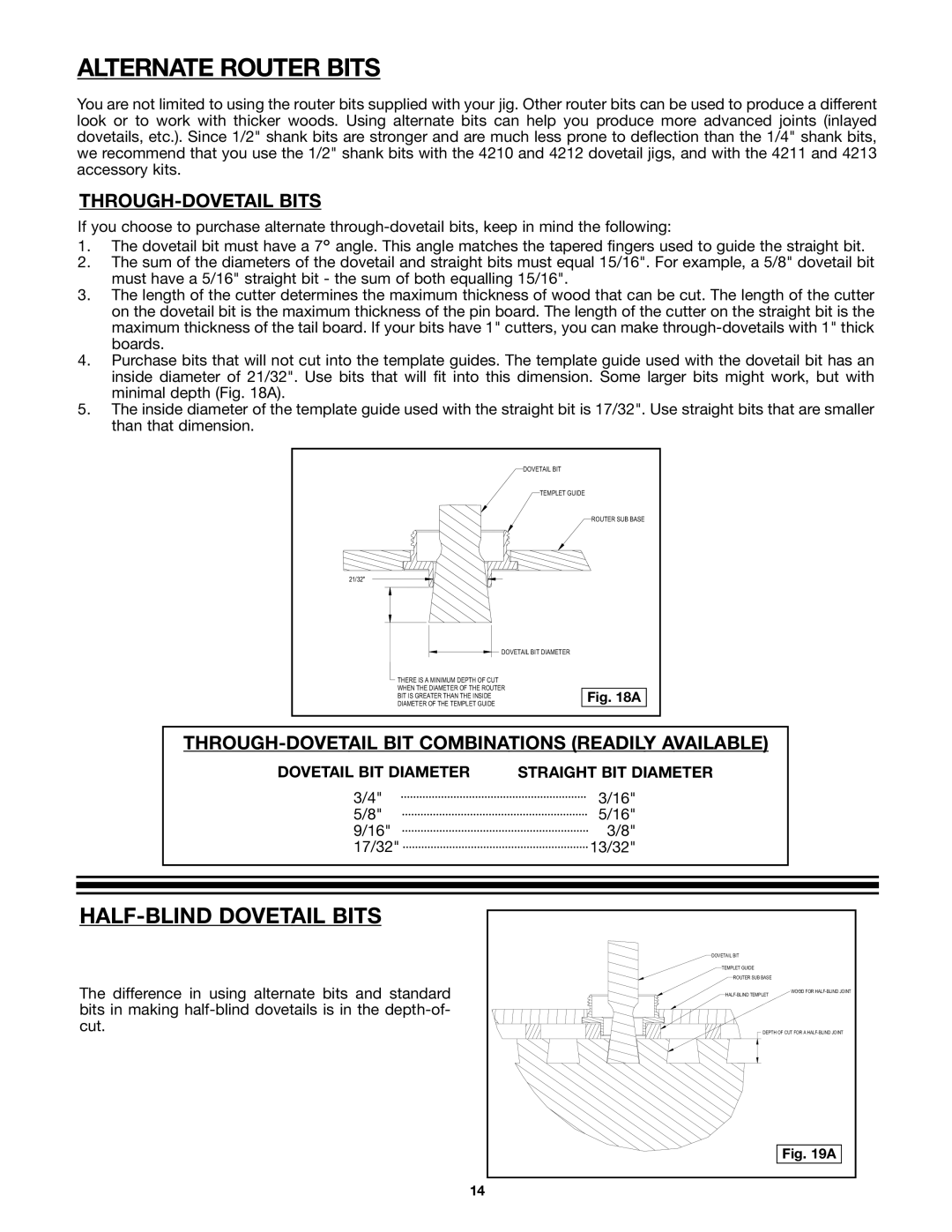

4.Purchase bits that will not cut into the template guides. The template guide used with the dovetail bit has an inside diameter of 21/32". Use bits that will fit into this dimension. Some larger bits might work, but with minimal depth (Fig. 18A).

5.The inside diameter of the template guide used with the straight bit is 17/32". Use straight bits that are smaller than that dimension.

DOVETAIL BIT

TEMPLET GUIDE

ROUTER SUB BASE

21/32"

DOVETAIL BIT DIAMETER

THERE IS A MINIMUM DEPTH OF CUT WHEN THE DIAMETER OF THE ROUTER BIT IS GREATER THAN THE INSIDE DIAMETER OF THE TEMPLET GUIDE

Fig. 18A

THROUGH-DOVETAIL BIT COMBINATIONS (READILY AVAILABLE)

DOVETAIL BIT DIAMETER |

| STRAIGHT BIT DIAMETER |

3/4" ![]()

![]() 3/16"

3/16"

5/8" ![]()

![]() 5/16"

5/16"

9/16" ![]()

![]() 3/8"

3/8"

17/32" ![]()

![]() 13/32"

13/32"

HALF-BLIND DOVETAIL BITS

The difference in using alternate bits and standard bits in making

DOVETAIL BIT |

TEMPLET GUIDE |

ROUTER SUB BASE |

WOOD FOR |

DEPTH OF CUT FOR A |

Fig. 19A |

14