TEMPLATES MOUNTED TO CLAMPING BOARDS

You can mount the jig templates to clamping boards and take the templates to the workpiece to make the joint. The benefits of this operation are:

1.You can maneuver a mounted template onto a large workpiece easier than clamping a large workpiece to the jig. This process allows you to join boards wider than 12" by routing a part of the joint, sliding the mounted template just past the original cut, and routing the remainder of the joint.

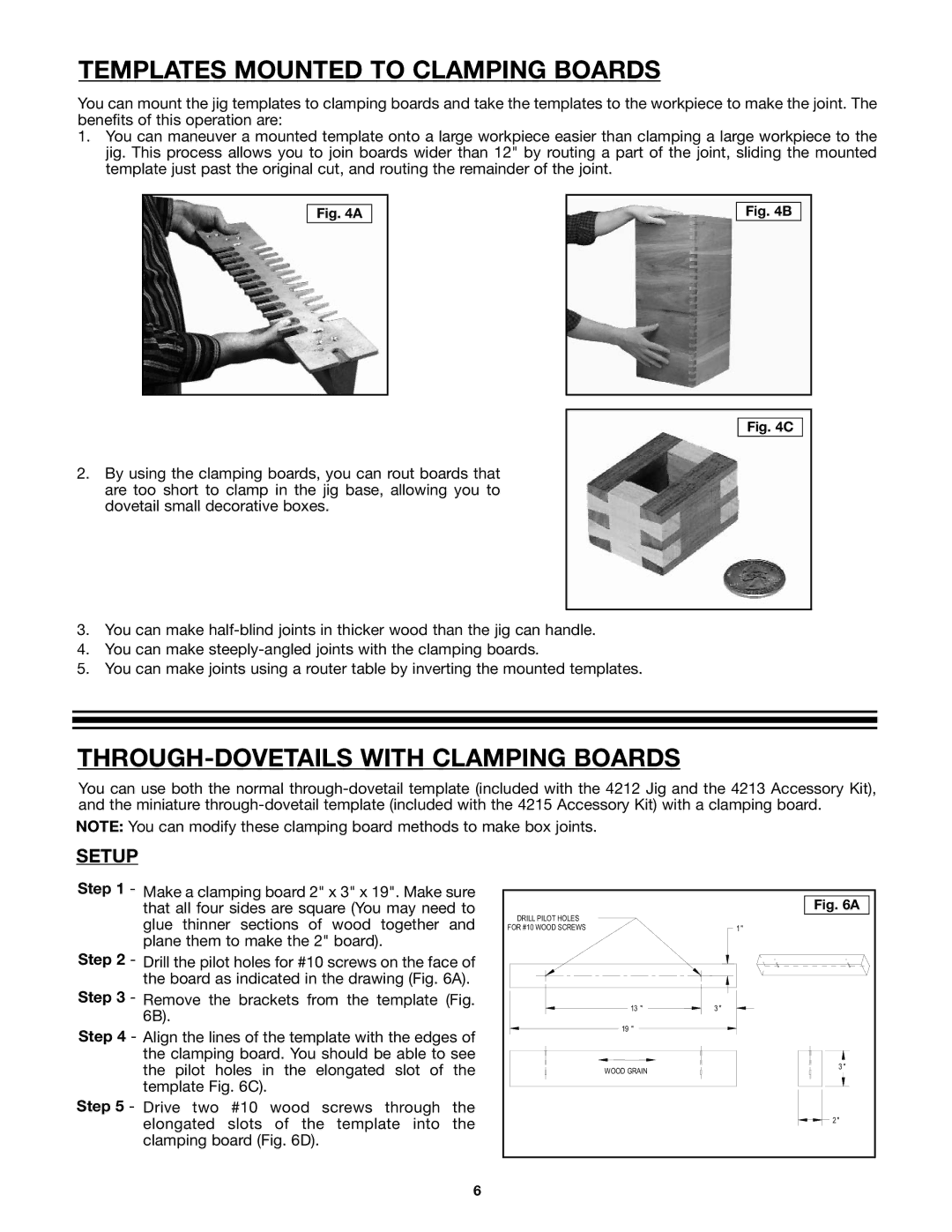

Fig. 4A

Fig. 4B

2.By using the clamping boards, you can rout boards that are too short to clamp in the jig base, allowing you to dovetail small decorative boxes.

Fig. 4C

3.You can make

4.You can make

5.You can make joints using a router table by inverting the mounted templates.

THROUGH-DOVETAILS WITH CLAMPING BOARDS

You can use both the normal

NOTE: You can modify these clamping board methods to make box joints.

SETUP

Step 1 - Make a clamping board 2" x 3" x 19". Make sure that all four sides are square (You may need to glue thinner sections of wood together and plane them to make the 2" board).

Step 2 - Drill the pilot holes for #10 screws on the face of the board as indicated in the drawing (Fig. 6A).

Step 3 - Remove the brackets from the template (Fig. 6B).

Step 4 - Align the lines of the template with the edges of the clamping board. You should be able to see the pilot holes in the elongated slot of the template Fig. 6C).

Step 5 - Drive two #10 wood screws through the elongated slots of the template into the clamping board (Fig. 6D).

| Fig. 6A |

DRILL PILOT HOLES |

|

FOR #10 WOOD SCREWS | 1 " |

13 " | 3 " |

19 " |

|

WOOD GRAIN | 3 " |

| |

| 2 " |

6