ANGLED JOINTS

You can join boards at angles other than 90°. Four different methods are shown below by using the through dovetail procedure.

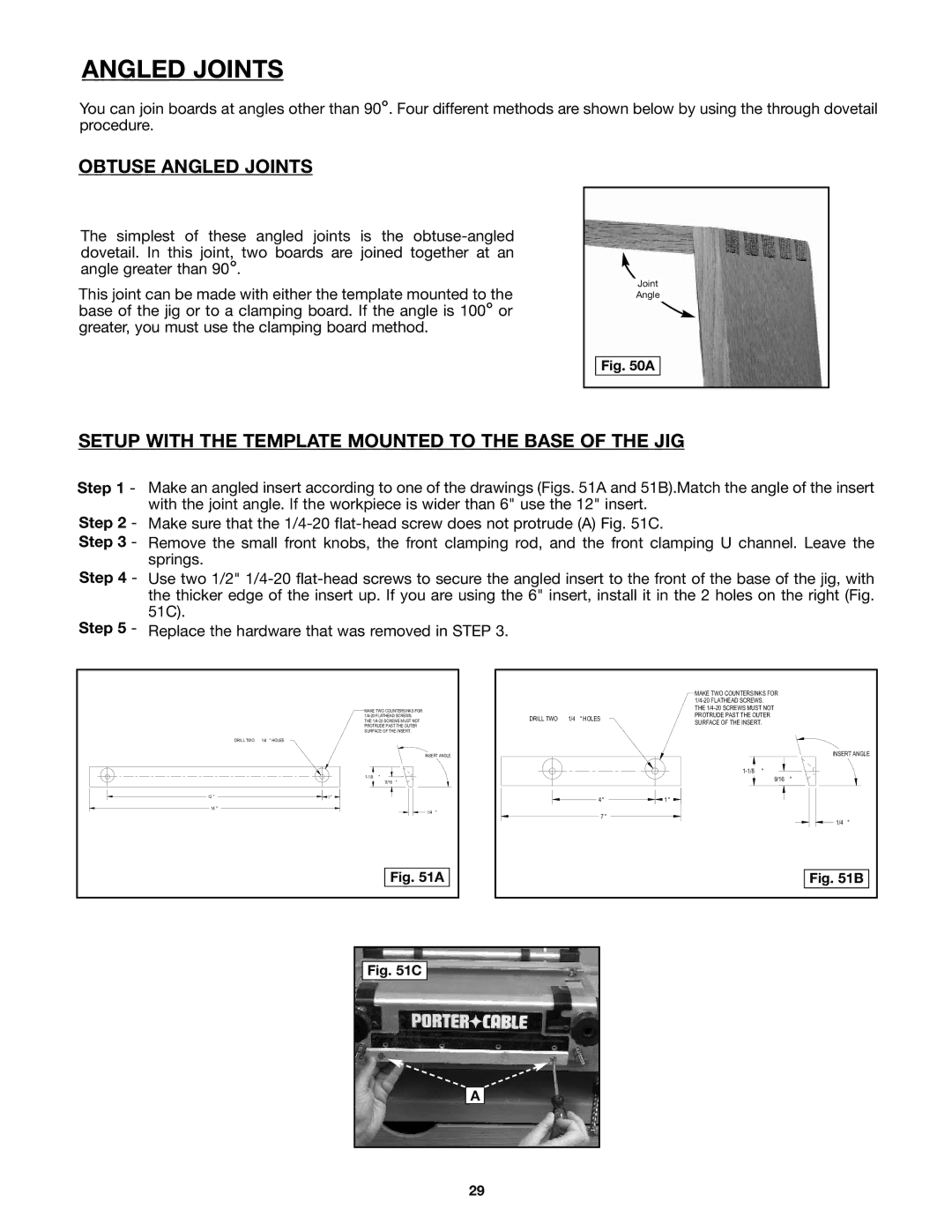

OBTUSE ANGLED JOINTS

The simplest of these angled joints is the

This joint can be made with either the template mounted to the base of the jig or to a clamping board. If the angle is 100° or greater, you must use the clamping board method.

Joint

Angle

Fig. 50A

SETUP WITH THE TEMPLATE MOUNTED TO THE BASE OF THE JIG

Step 1 -

Step 2 - Step 3 -

Step 4 -

Step 5 -

Make an angled insert according to one of the drawings (Figs. 51A and 51B).Match the angle of the insert with the joint angle. If the workpiece is wider than 6" use the 12" insert.

Make sure that the

Remove the small front knobs, the front clamping rod, and the front clamping U channel. Leave the springs.

Use two 1/2"

Replace the hardware that was removed in STEP 3.

MAKE TWO COUNTERSINKS FOR

DRILL TWO 1/4 " HOLES

INSERT ANGLE

| " |

|

| |

|

| 9/16 | " |

|

12 " | 1 " |

|

|

|

14 " |

|

| 1/4 | " |

|

|

|

DRILL TWO 1/4 " HOLES

4 " | 1 " |

7 " |

|

MAKE TWO COUNTERSINKS FOR

![]() 9/16 "

9/16 "

INSERT ANGLE

1/4 "

Fig. 51A

Fig. 51B

Fig. 51C |

A |

29 |