CUTTING THE TAILS

Cut the tail board (drawer side) similar to cutting the rabbeted

NOTE: Support the template with a scrap workpiece thick enough to prevent the cutter from contacting the base.

CUTTING THE PINS

Cut the pin board (drawer front) similar to cutting the rabbeted

NOTE: Ensure that the pin board (drawer front) is thicker than the depth of cut to prevent the cutter from contacting the base.

FITTING THE JOINT

Fit the joint the same as you would a standard rabbeted

NOTE: If a change in

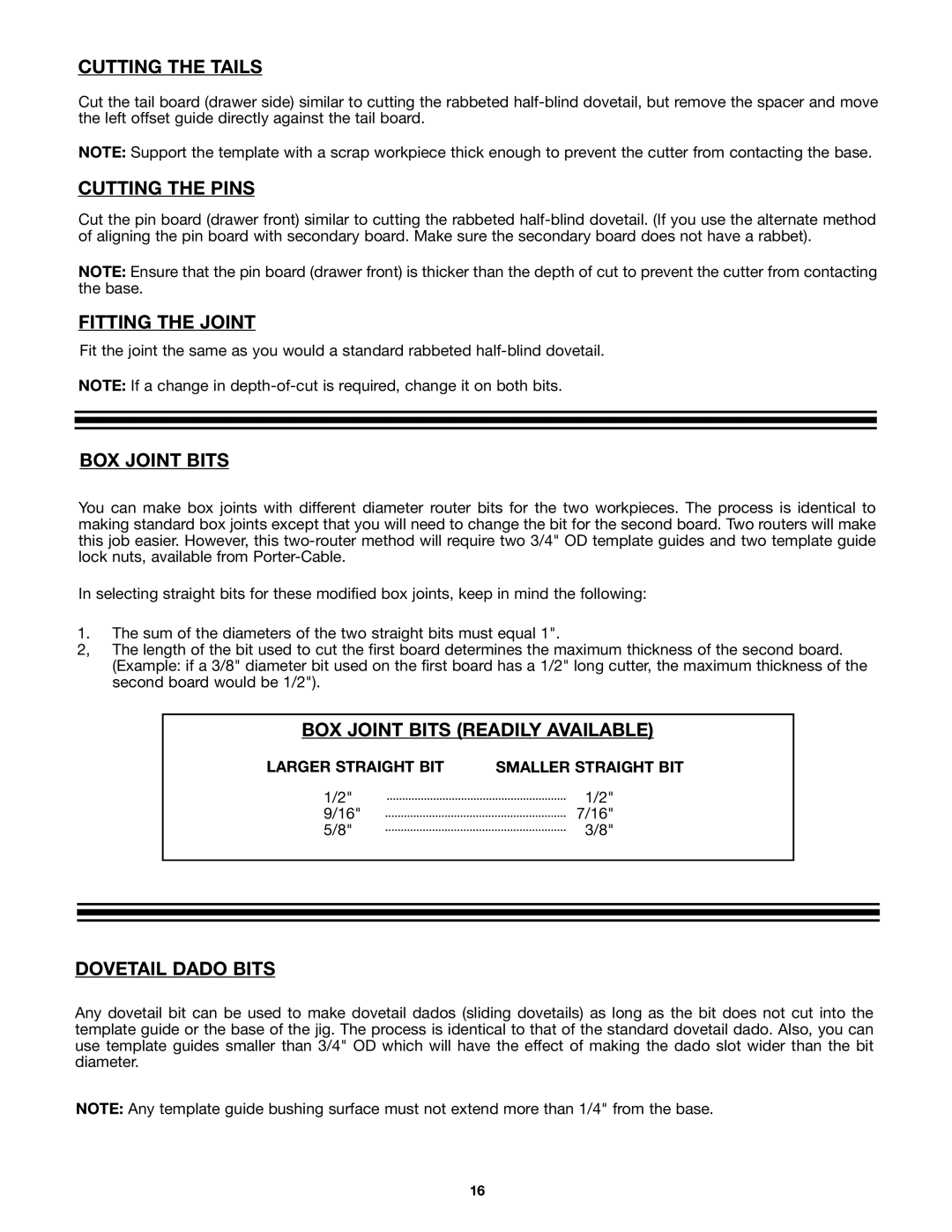

BOX JOINT BITS

You can make box joints with different diameter router bits for the two workpieces. The process is identical to making standard box joints except that you will need to change the bit for the second board. Two routers will make this job easier. However, this

In selecting straight bits for these modified box joints, keep in mind the following:

1.The sum of the diameters of the two straight bits must equal 1".

2, The length of the bit used to cut the first board determines the maximum thickness of the second board. (Example: if a 3/8" diameter bit used on the first board has a 1/2" long cutter, the maximum thickness of the second board would be 1/2").

BOX JOINT BITS (READILY AVAILABLE)

LARGER STRAIGHT BIT |

| SMALLER STRAIGHT BIT |

|

|

|

1/2" ![]()

![]() 1/2"

1/2"

9/16" ![]()

![]() 7/16"

7/16"

5/8" ![]()

![]() 3/8"

3/8"

DOVETAIL DADO BITS

Any dovetail bit can be used to make dovetail dados (sliding dovetails) as long as the bit does not cut into the template guide or the base of the jig. The process is identical to that of the standard dovetail dado. Also, you can use template guides smaller than 3/4" OD which will have the effect of making the dado slot wider than the bit diameter.

NOTE: Any template guide bushing surface must not extend more than 1/4" from the base.

16