R

VOYAGEUR Wood Insert

E. Metal Heat Circulating Masonry

This insert conforms with the safety standard

F. Prefabricated Metal Chimney

The chimney can be new or existing, masonry or prefabricated and must meet the following minimum requirements:

•Must be minimum 6 inch (152mm) inside diameter of high temperature chimney listed to UL 103 HT (2100oF) or ULC S628.

•Must use components required by the manufacturer for installation.

•Must maintain clearances required by the manufacturer for installation.

•Refer to manufacturers instructions for installation

•This insert is listed to UL 1482 Standard and is approved for installation into listed

•The original

•The liner must be securely attached to the insert fl ue collar and the chimney top.

•The air fl ow of the

•No dilution air is allowed to enter the chimney.

1.Secure the fi replace damper in the open position. If this cannot be accomplished, it will be necessary to remove the damper.

2.Seal damper area of chimney around chimney connector with a high temperature sealant or seal insert against the face of the fi replace.

3.Both methods must be removable and replaceable for cleaning and

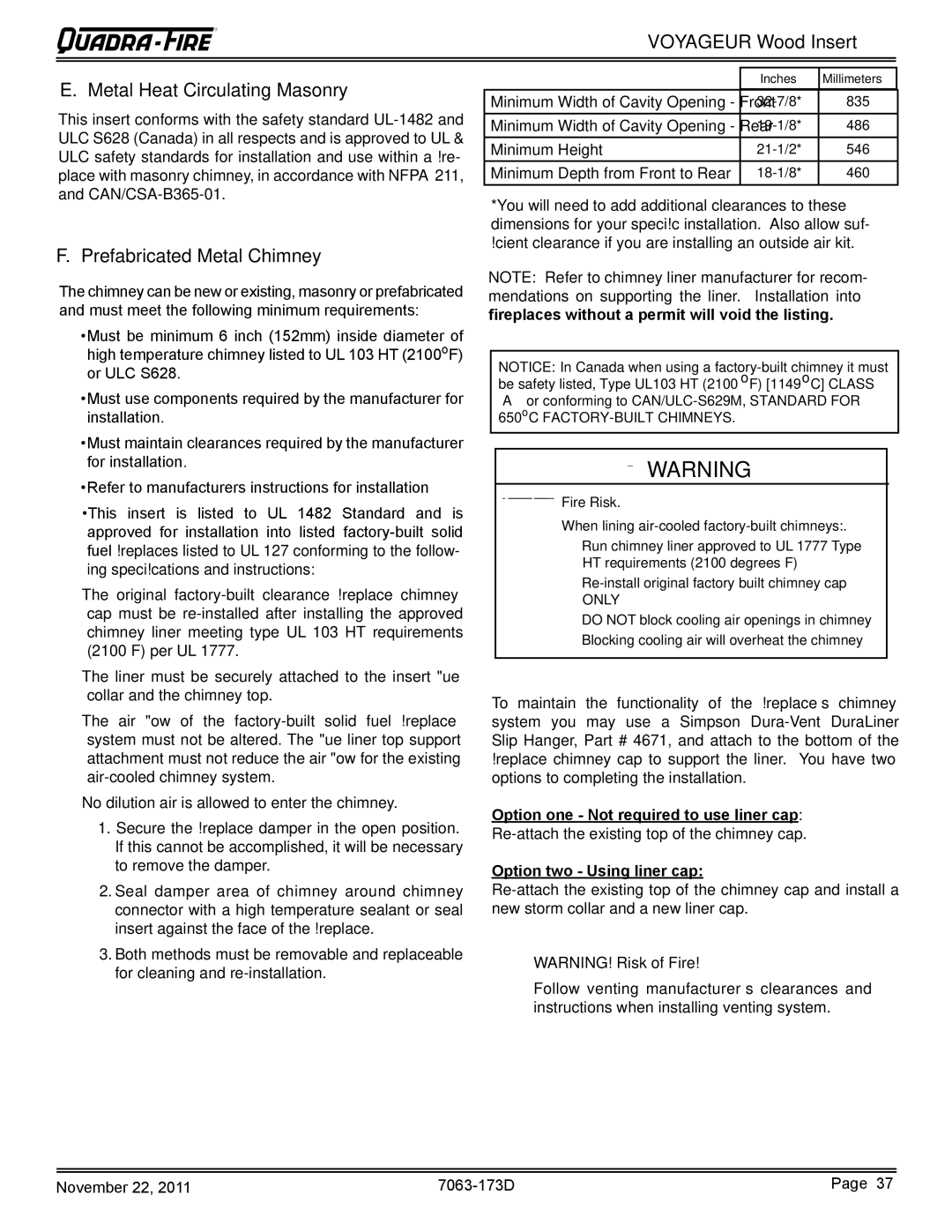

| Inches | Millimeters |

|

|

|

Minimum Width of Cavity Opening - Front | 835 | |

|

|

|

Minimum Width of Cavity Opening - Rear | 486 | |

|

|

|

Minimum Height | 546 | |

Minimum Depth from Front to Rear | 460 | |

|

|

|

*You will need to add additional clearances to these dimensions for your specifi c installation. Also allow suf- fi cient clearance if you are installing an outside air kit.

NOTE: Refer to chimney liner manufacturer for recom- mendations on supporting the liner. Installation into

fireplaces without a permit will void the listing.

NOTICE: In Canada when using a

“A” or conforming to

WARNING

Fire Risk.

When lining

•Run chimney liner approved to UL 1777 Type HT requirements (2100 degrees F)

•

ONLY

•DO NOT block cooling air openings in chimney

•Blocking cooling air will overheat the chimney

To maintain the functionality of the fi replace’s chimney system you may use a Simpson

fireplace chimney cap to support the liner. You have two options to completing the installation.

Option one - Not required to use liner cap:

Option two - Using liner cap:

WARNING! Risk of Fire!

Follow venting manufacturer’s clearances and instructions when installing venting system.

November 22, 2011 | Page 37 |