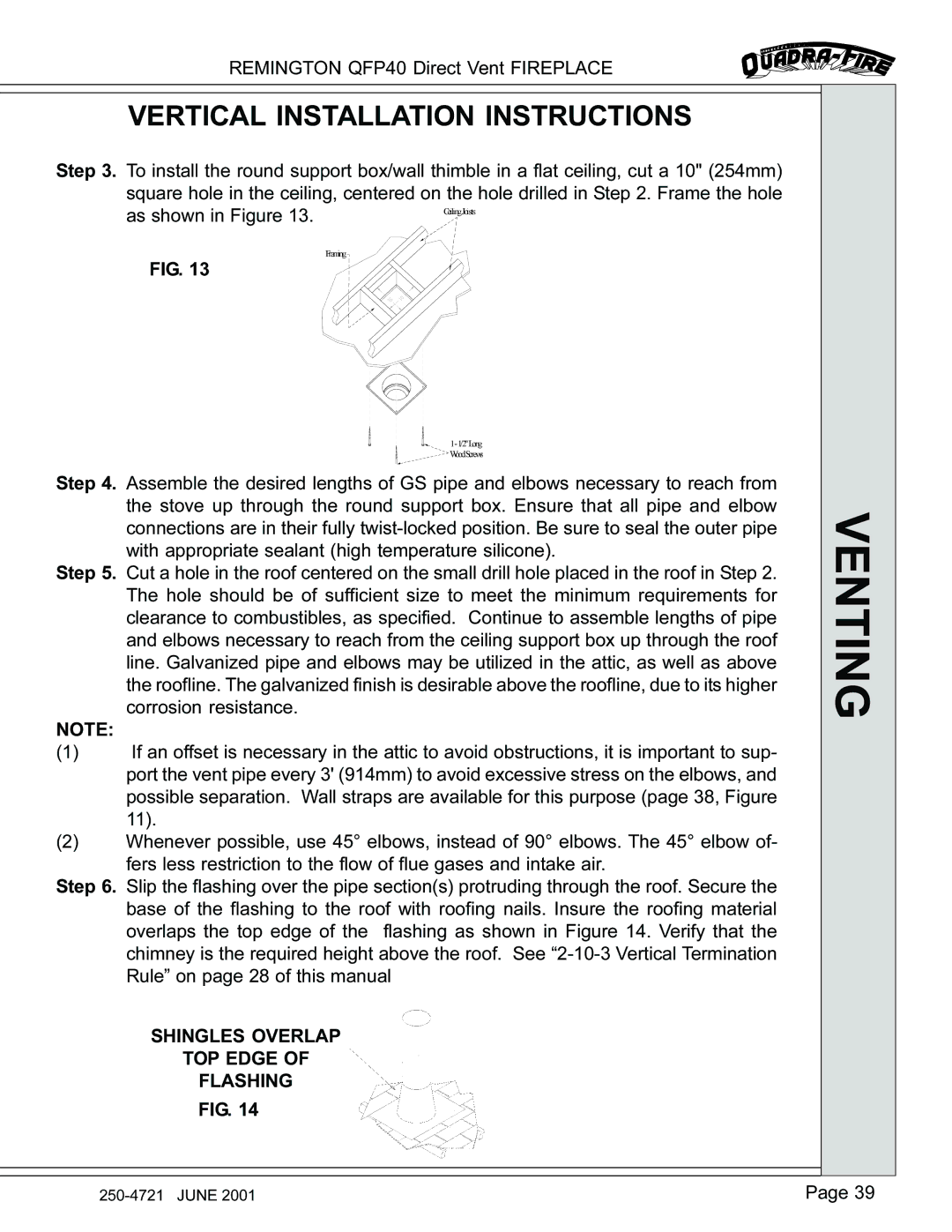

SHINGLES OVERLAP

TOP EDGE OF

FLASHING FIG. 14

(2) Step 6.

If an offset is necessary in the attic to avoid obstructions, it is important to sup- port the vent pipe every 3' (914mm) to avoid excessive stress on the elbows, and possible separation. Wall straps are available for this purpose (page 38, Figure 11).

Whenever possible, use 45° elbows, instead of 90° elbows. The 45° elbow of- fers less restriction to the flow of flue gases and intake air.

Slip the flashing over the pipe section(s) protruding through the roof. Secure the base of the flashing to the roof with roofing nails. Insure the roofing material overlaps the top edge of the flashing as shown in Figure 14. Verify that the chimney is the required height above the roof. See “2-10-3 Vertical Termination Rule” on page 28 of this manual

NOTE:

(1)

Framing

FIG. 13

1 -1/2"Long

Wood Screws

Step 4. Assemble the desired lengths of GS pipe and elbows necessary to reach from the stove up through the round support box. Ensure that all pipe and elbow connections are in their fully twist-locked position. Be sure to seal the outer pipe with appropriate sealant (high temperature silicone).

Step 5. Cut a hole in the roof centered on the small drill hole placed in the roof in Step 2. The hole should be of sufficient size to meet the minimum requirements for clearance to combustibles, as specified. Continue to assemble lengths of pipe and elbows necessary to reach from the ceiling support box up through the roof line. Galvanized pipe and elbows may be utilized in the attic, as well as above the roofline. The galvanized finish is desirable above the roofline, due to its higher corrosion resistance.

To install the round support box/wall thimble in a flat ceiling, cut a 10" (254mm) square hole in the ceiling, centered on the hole drilled in Step 2. Frame the hole

as shown in Figure 13.Ceiling Joists

Step 3.

REMINGTON QFP40 Direct Vent FIREPLACE

VERTICAL INSTALLATION INSTRUCTIONS

VENTING

Page 39