VENTING

REMINGTON QFP40 Direct Vent FIREPLACE

VERTICAL INSTALLATION INSTRUCTIONS (CONT.)

USING GS SERIES PIPE (CONT.)

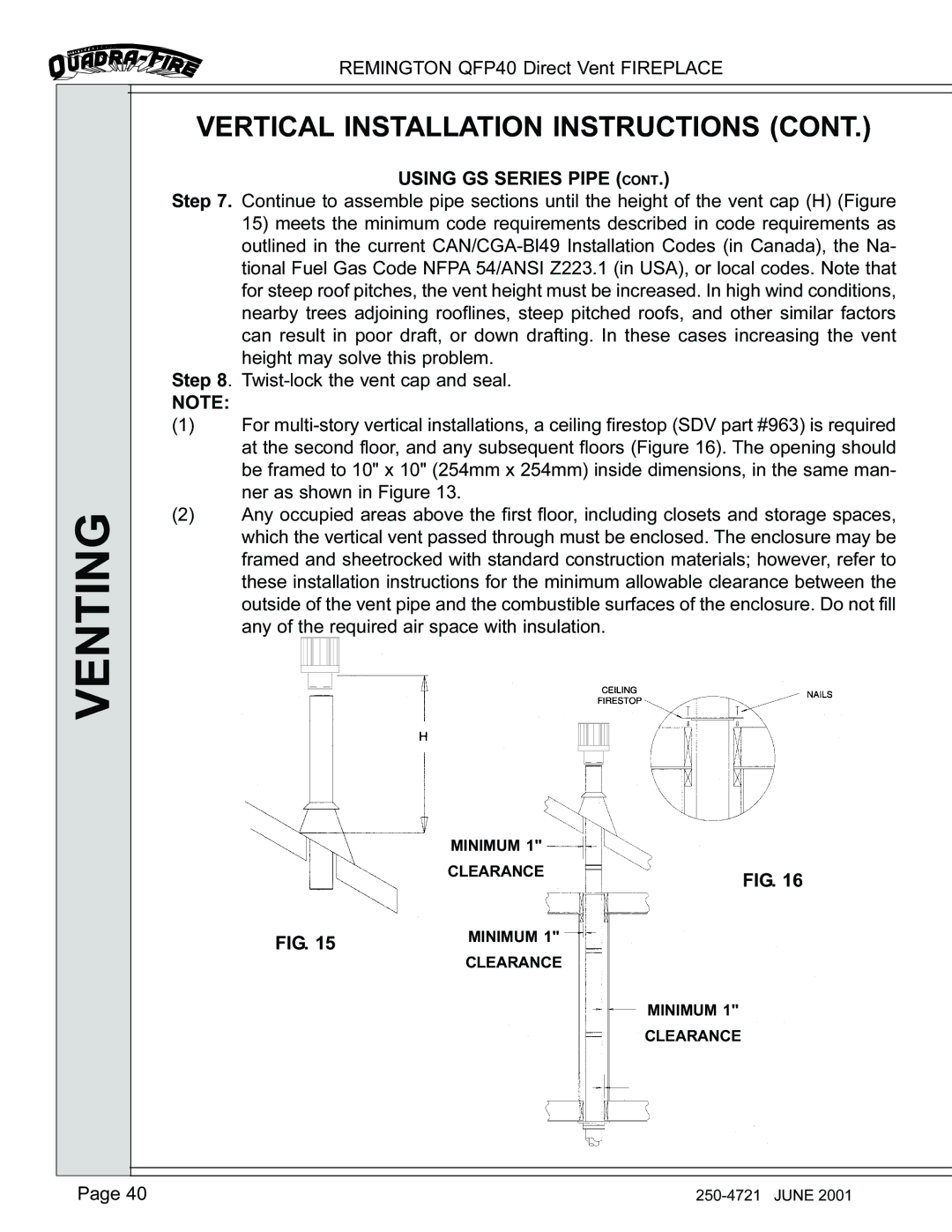

Step 7. Continue to assemble pipe sections until the height of the vent cap (H) (Figure

15)meets the minimum code requirements described in code requirements as outlined in the current

Step 8.

NOTE:

(1)For

(2)Any occupied areas above the first floor, including closets and storage spaces, which the vertical vent passed through must be enclosed. The enclosure may be framed and sheetrocked with standard construction materials; however, refer to these installation instructions for the minimum allowable clearance between the outside of the vent pipe and the combustible surfaces of the enclosure. Do not fill any of the required air space with insulation.

MINIMUM 1"

CLEARANCE

FIG. 16

FIG. 15 | MINIMUM 1" |

| |

| CLEARANCE |

MINIMUM 1"

CLEARANCE

Page 40 |