Alignment

Make Blade Parallel to Table

The goal of this adjustment is to keep the workpiece from being thrown or damaged. This adjustment will also reduce splintering of the workpiece and burning of the kerf dur- ing ripping and crosscutting.

1.Lock arm in 0°miter crosscut position.

2.Pull blade forward and tighten carriage lock knob.

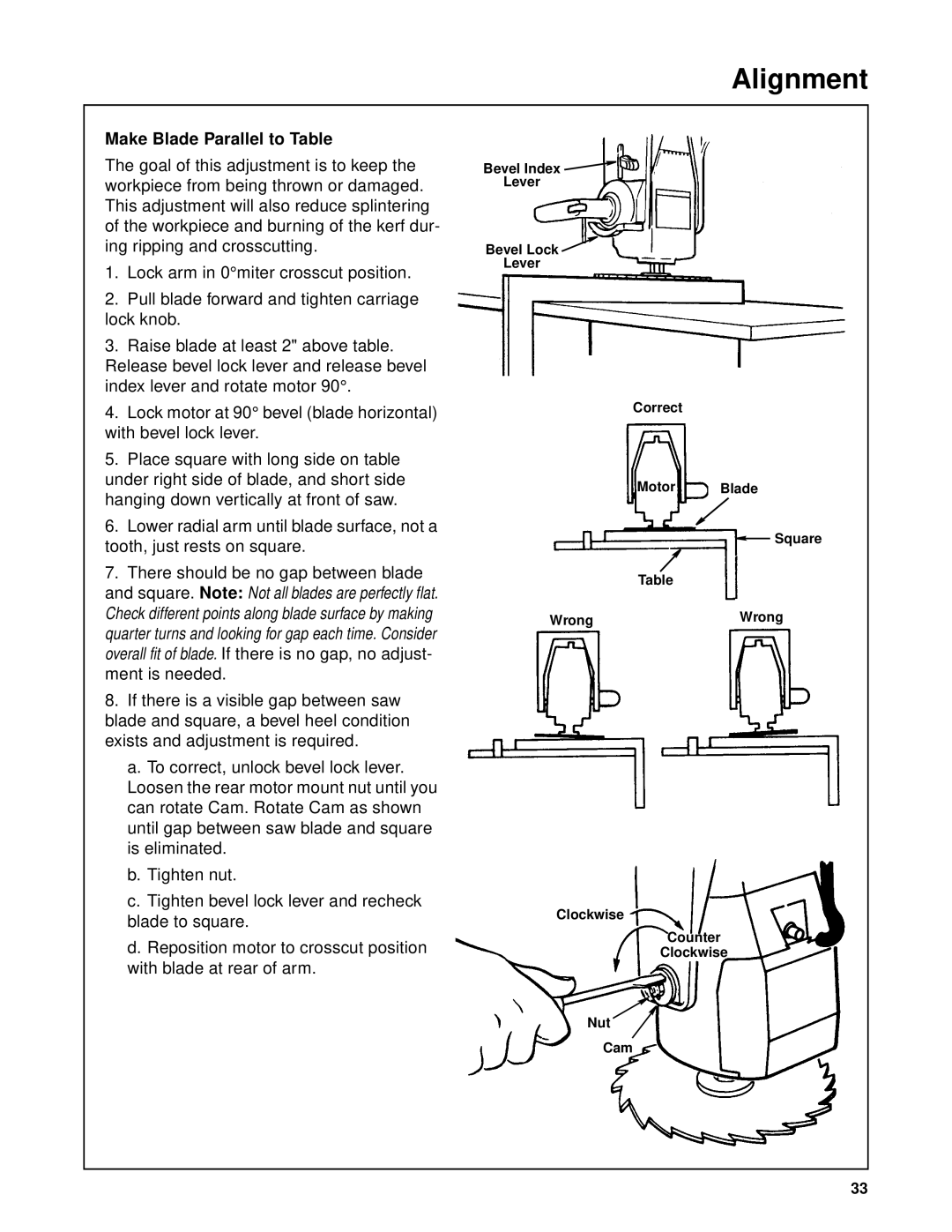

3.Raise blade at least 2" above table. Release bevel lock lever and release bevel index lever and rotate motor 90°.

4.Lock motor at 90° bevel (blade horizontal) with bevel lock lever.

5.Place square with long side on table under right side of blade, and short side hanging down vertically at front of saw.

6.Lower radial arm until blade surface, not a tooth, just rests on square.

7.There should be no gap between blade and square. Note: Not all blades are perfectly flat. Check different points along blade surface by making quarter turns and looking for gap each time. Consider overall fit of blade. If there is no gap, no adjust- ment is needed.

8.If there is a visible gap between saw blade and square, a bevel heel condition exists and adjustment is required.

a.To correct, unlock bevel lock lever. Loosen the rear motor mount nut until you can rotate Cam. Rotate Cam as shown until gap between saw blade and square is eliminated.

b.Tighten nut.

c.Tighten bevel lock lever and recheck blade to square.

d.Reposition motor to crosscut position with blade at rear of arm.

Bevel Index ![]()

Lever

Bevel Lock ![]()

Lever

Correct

Motor Blade

![]() Square

Square

Table

Wrong | Wrong |

Clockwise

Counter

Clockwise

Nut

Cam

33