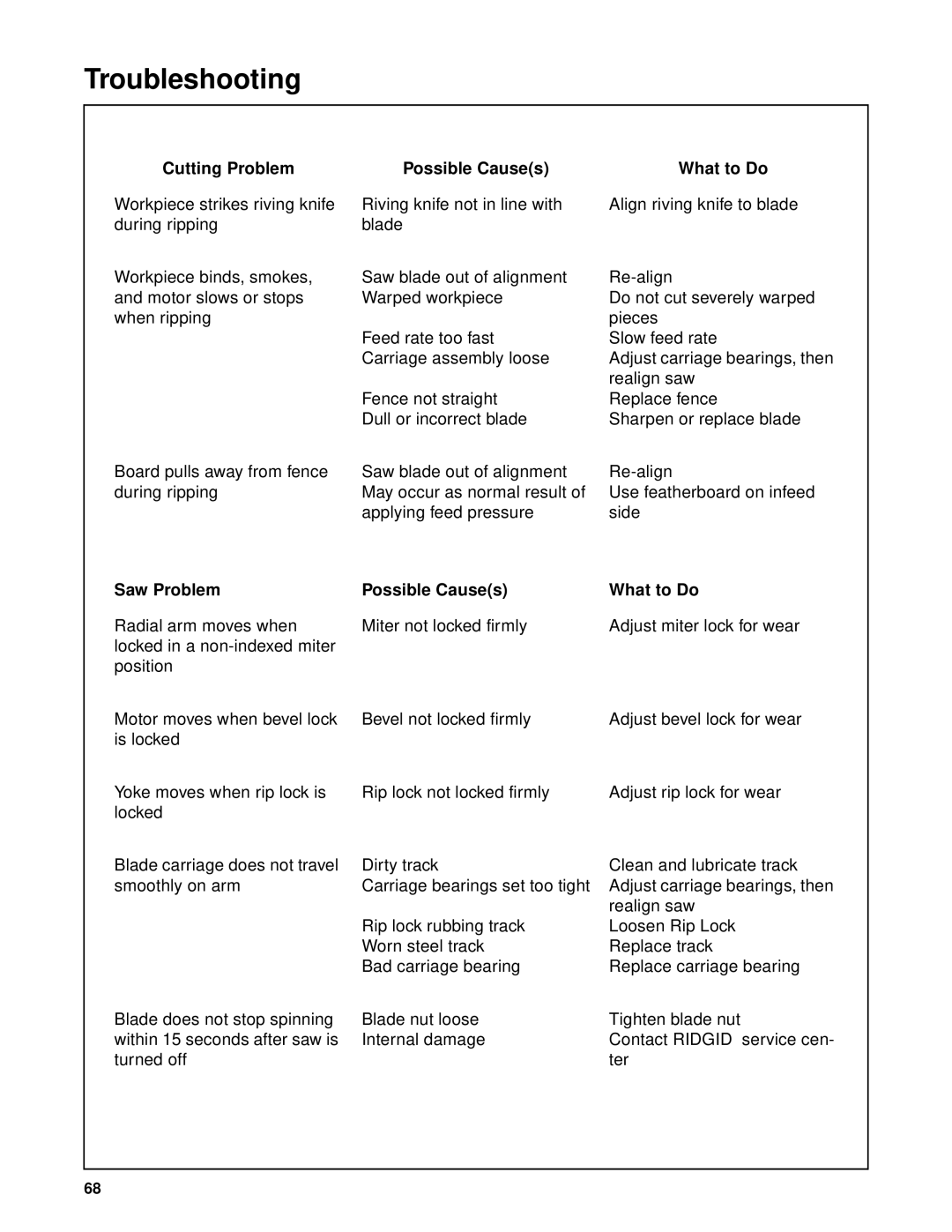

Troubleshooting

Cutting Problem | Possible Cause(s) | What to Do |

Workpiece strikes riving knife | Riving knife not in line with | Align riving knife to blade |

during ripping | blade |

|

Workpiece binds, smokes, | Saw blade out of alignment | |

and motor slows or stops | Warped workpiece | Do not cut severely warped |

when ripping |

| pieces |

| Feed rate too fast | Slow feed rate |

| Carriage assembly loose | Adjust carriage bearings, then |

|

| realign saw |

| Fence not straight | Replace fence |

| Dull or incorrect blade | Sharpen or replace blade |

Board pulls away from fence during ripping

Saw blade out of alignment | |

May occur as normal result of | Use featherboard on infeed |

applying feed pressure | side |

Saw Problem

Radial arm moves when locked in a

Motor moves when bevel lock is locked

Yoke moves when rip lock is locked

Blade carriage does not travel smoothly on arm

Possible Cause(s) | What to Do |

Miter not locked firmly | Adjust miter lock for wear |

Bevel not locked firmly | Adjust bevel lock for wear |

Rip lock not locked firmly | Adjust rip lock for wear |

Dirty track | Clean and lubricate track |

Carriage bearings set too tight | Adjust carriage bearings, then |

| realign saw |

Rip lock rubbing track | Loosen Rip Lock |

Worn steel track | Replace track |

Bad carriage bearing | Replace carriage bearing |

Blade does not stop spinning | Blade nut loose | Tighten blade nut |

within 15 seconds after saw is | Internal damage | Contact RIDGID service cen- |

turned off |

| ter |

68