Troubleshooting

HAVE YOU FOLLOWED ALL STEPS OF THE

ALIGNMENT PROCEDURE? IF YOU HAVE

NOT FOLLOWED THEM IN THEIR PROPER

SEQUENCE, YOU CANNOT EXPECT ACCU-

RATE CUTTING RESULTS.

In addition to the proper alignment of your saw, you must also become familiar with the following practices in order to expect the best results.

1.Edge of workpiece which is placed against fence must be as straight as the long side of your framing square.

2.Workpiece must be as flat as the front table board on your saw.

3.There must be no sawdust or other wood chips between the fence and the front table board.

4.There must be no sawdust or other wood chips underneath workpiece or between- workpiece and fence.

5.Workpiece must be held tightly against fence and down against the table...this is especially important when making angle cuts because the workpiece has a tendency to move.

6.Always use the correct sawblade for the job. Always keep it sharp.

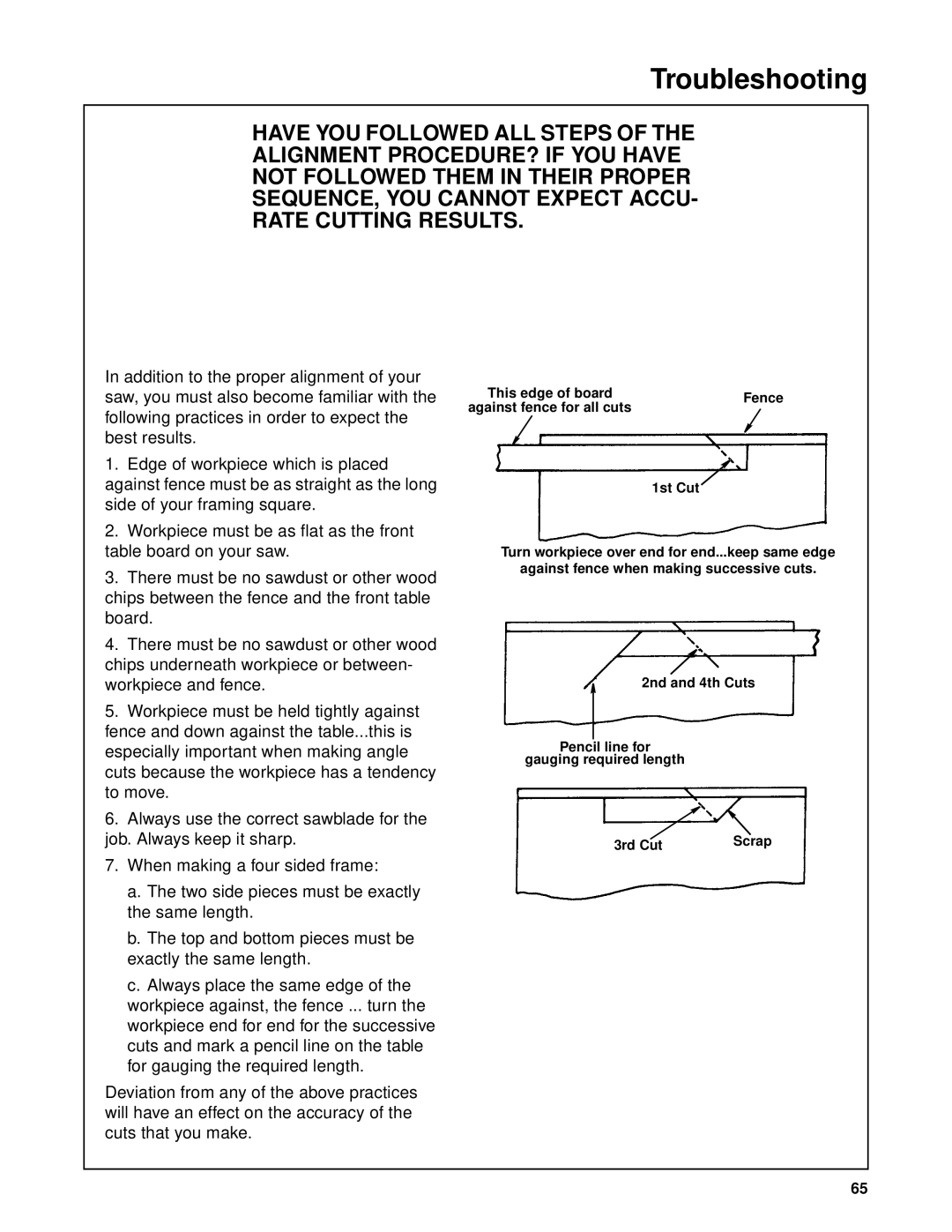

7.When making a four sided frame:

a.The two side pieces must be exactly the same length.

b.The top and bottom pieces must be exactly the same length.

c.Always place the same edge of the workpiece against, the fence ... turn the workpiece end for end for the successive cuts and mark a pencil line on the table for gauging the required length.

Deviation from any of the above practices will have an effect on the accuracy of the cuts that you make.

This edge of board | Fence | |

against fence for all cuts | ||

|

1st Cut

Turn workpiece over end for end...keep same edge

against fence when making successive cuts.

2nd and 4th Cuts

Pencil line for

gauging required length

3rd Cut | Scrap |

|

65